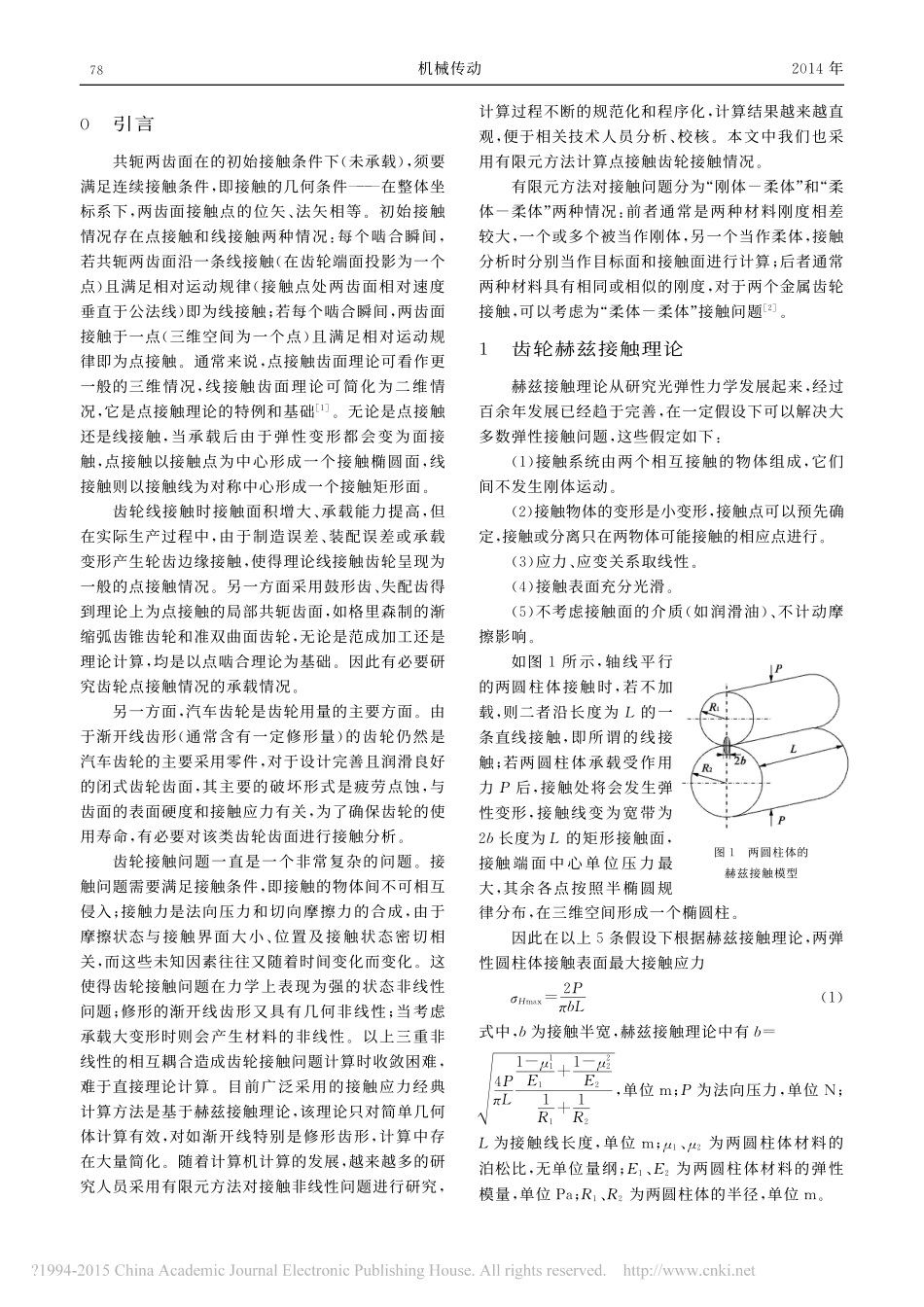

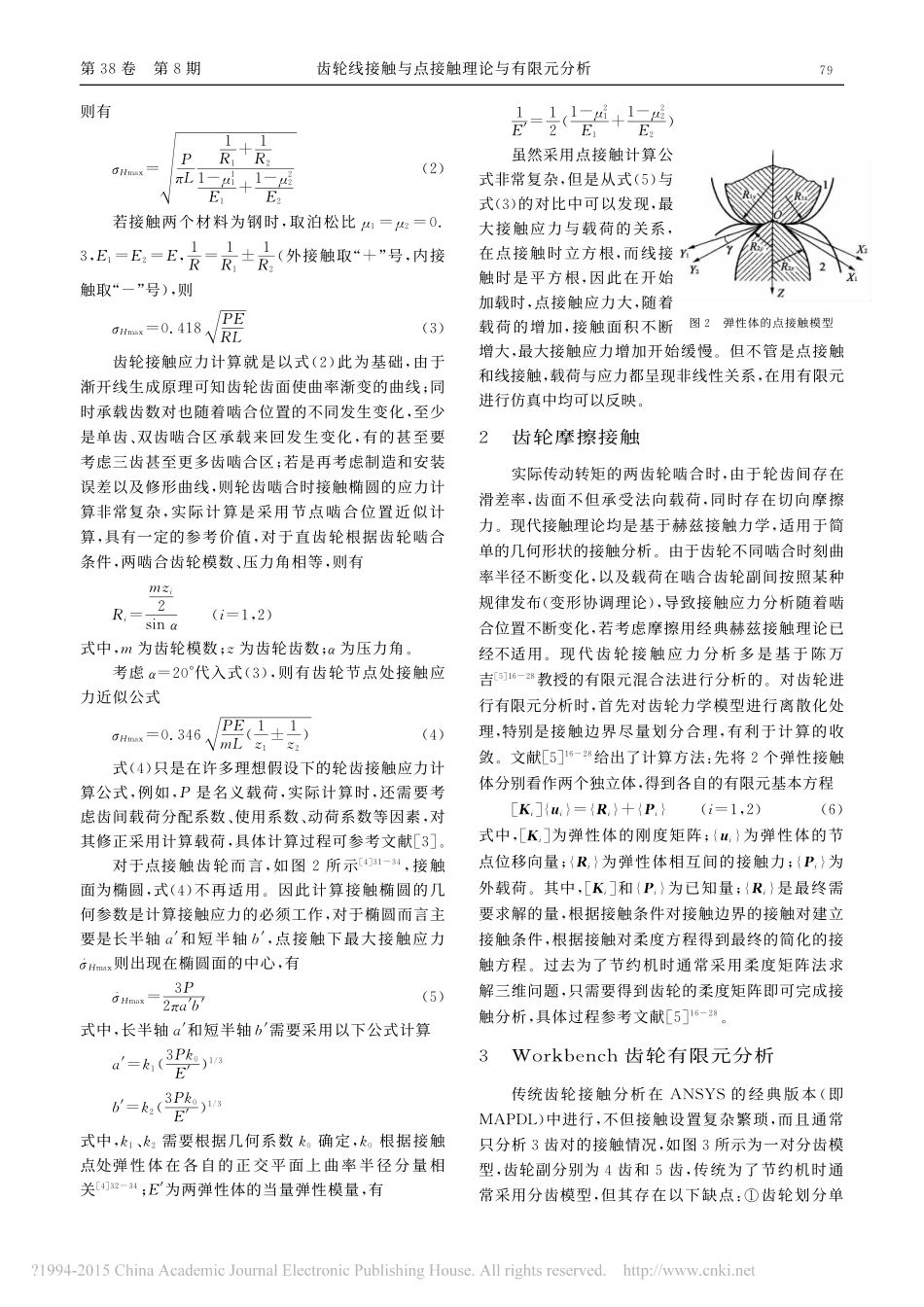

文章编号:1004-2539(2014)08-0077-05齿轮线接触与点接触理论与有限元分析徐恺1苏建新1周永丹2邱明1王伟生3(1河南科技大学机电工程学院,河南洛阳471003)(2中色科技股份有限公司,河南洛阳471039)(3韶能集团韶关宏大齿轮有限公司技术开发部,广东韶关512029)摘要由于制造误差、安装误差、支撑条件、齿轮承载变形等因素的影响,齿轮接触情况复杂且难以试验验证。齿轮接触按照初始接触条件通常分为线接触和点接触,承载后均为面接触:前者接触面为矩形,后者为椭圆形。线接触理论利用赫兹接触理论已经成熟,即采用两个圆柱体的线接触方式进行计算;点接触理论计算较为复杂,须考虑接触椭圆和其他非线性因素。用有限元方法分析渐开线及其修形齿轮的接触状态,计算实例表明,没有考虑安装误差的影响,线接触的仿真结果与赫兹接触理论相吻合,且接触状况明显好于点接触;当考虑安装误差的影响,二者接触应力均有上升,但线接触的接触状况明显恶化,接触应力急剧上升57倍以上,而点接触的接触应力上升不到1倍,说明齿轮线接触对安装误差的敏感性远大于齿轮点接触,极易造成齿轮的点蚀破坏。关键词齿轮接触分析赫兹接触点接触线接触ANSYSWorkbenchTheoreticalFormulaandFiniteElementAnalysisbetweenGearPairswithLineContactandPointContactXuKai1SuJianxin1ZhouYongdan2QiuMing1WangWeisheng3(1SchoolofMechatronicsEngineering,HenanUniversityofScienceandTechnology,Luoyang471003,China)(2ChinaNonferrousMetalsProcessingTechnologyCo.,Ltd.,Luoyang471039,China)(3TechnologyR&DDepartment,ShaonengGroupShaoguanHongdaGearCo.,Ltd.,Shaoguan512029,China)AbstractThegearcontactstressisverydifficulttocalculateandtestowingtocomplexityofgearpairscontactconditionbymanufacturingerror,assemblyerror,supportconditions,deformationofloadedgearpairs,etc.Thegearcontactcanbeconstitutedoflinecontactandpointcontactinnon-loadedcondition,andwillbechangetosurfacecontactinloadedcondition.Whentheloadisap-plied,theareaofthecontactisrectangularandellipserespectivelyinlinecontactandpointcontact.ThetheoryoflinecontactisperfectusingHertzcontacttocalculatetwocylinderscontact.Howeverthetheoryofpointcontactismorecomplicatedconsideringcontactellipseandothernonlinearfactors,etc.Thecalculationexamplesofinvolutegearandthesameparametergearwithmodificationareana-lyzedbyfiniteelementmethod.Itshowsthatthesimulationresultofgearlinecon...