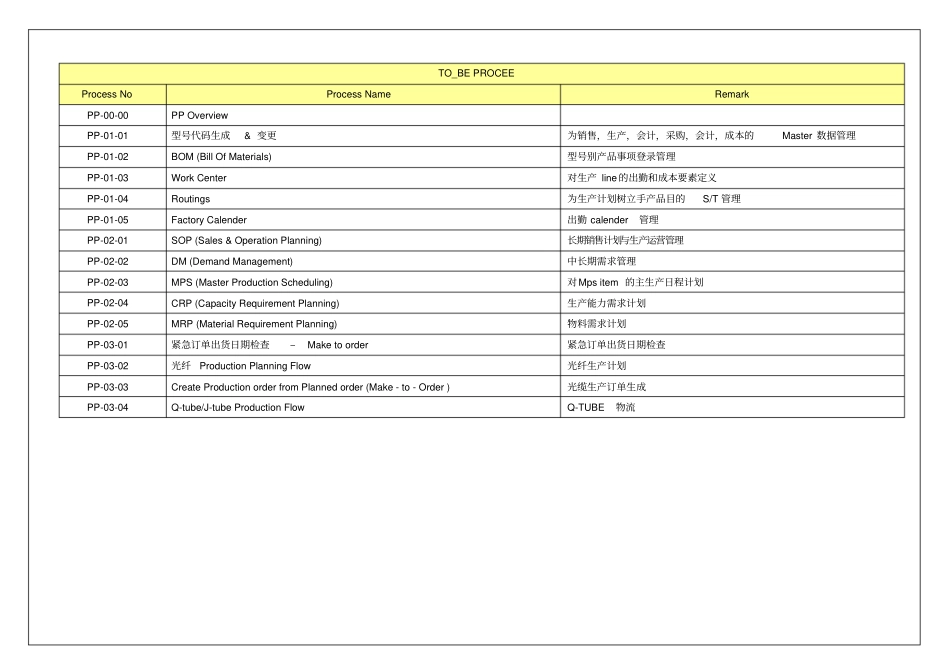

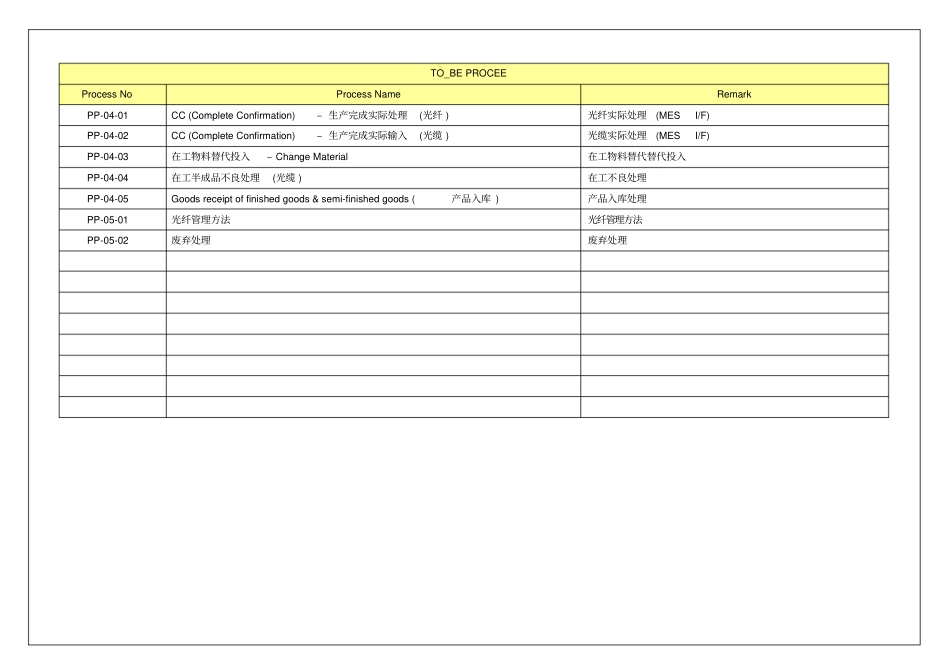

Planning&Prod.controlTo-BeProcessAugust.2004SEHFERPProjectTeamTO_BEPROCEEProcessNoProcessNameRemarkPP-00-00PPOverviewPP-01-01型号代码生成&变更为销售,生产,会计,采购,会计,成本的Master数据管理PP-01-02BOM(BillOfMaterials)型号别产品事项登录管理PP-01-03WorkCenter对生产line的出勤和成本要素定义PP-01-04Routings为生产计划树立手产品目的S/T管理PP-01-05FactoryCalender出勤calender管理PP-02-01SOP(Sales&OperationPlanning)长期销售计划与生产运营管理PP-02-02DM(DemandManagement)中长期需求管理PP-02-03MPS(MasterProductionScheduling)对Mpsitem的主生产日程计划PP-02-04CRP(CapacityRequirementPlanning)生产能力需求计划PP-02-05MRP(MaterialRequirementPlanning)物料需求计划PP-03-01紧急订单出货日期检查–Maketoorder紧急订单出货日期检查PP-03-02光纤ProductionPlanningFlow光纤生产计划PP-03-03CreateProductionorderfromPlannedorder(Make-to-Order)光缆生产订单生成PP-03-04Q-tube/J-tubeProductionFlowQ-TUBE物流TO_BEPROCEEProcessNoProcessNameRemarkPP-04-01CC(CompleteConfirmation)–生产完成实际处理(光纤)光纤实际处理(MESI/F)PP-04-02CC(CompleteConfirmation)–生产完成实际输入(光缆)光缆实际处理(MESI/F)PP-04-03在工物料替代投入–ChangeMaterial在工物料替代替代投入PP-04-04在工半成品不良处理(光缆)在工不良处理PP-04-05Goodsreceiptoffinishedgoods&semi-finishedgoods(产品入库)产品入库处理PP-05-01光纤管理方法光纤管理方法PP-05-02废弃处理废弃处理TO-BEPROCESSProcessnamePPOverviewPROCESSNOPP-00-00SalesProductionplanningProductionQCPurchasingfromVendorMES/Production(生产)Pur.Req.(采购请求书)Purorder(采购订单)ProductionplanDM(需求管理)MPS(基础生产计划)Plannedorder(计划订单)ProductionorderSalesforecasting(销售预测)Completeconf.(生产完成实际输入)Picklist(物料list)Materialreceipt(物料入库)Materialissue(物料出库)MES/OutgoingInsp.DeliveryDeliverynoteMaterialmasterBOMWorkcenterRoutings生产策略1050Salesorder(销售订单)SOP(销售运作计划)一次MRP(物料需求计划)CRP(生产能力计划)Fiber光纤生产计划二次MRP(物料需求计划)Goodsreceipt(产品入库)TO-BEPROCESSProcessname型号代码登录PROCESSNOPP-01-01区分市场部研发部生产管理财务RemarkCIS信息1.CIS->SAPI/F实行2.QMVIEW除外SAP型号代码登录委托检查承认自动生成BasicSalesMRPStorageAcct.CostingWorkSch确认字符/修整BasicMRPStorageWorkSch.确认字符/修整Sales确认字符/修整Acct.CostingI/FTO-BEPROCESSProcessnameBOM生成PROCESSNOPP-01-02区分市场部研发部RemarkCIS1.CIS->PDM->SAPI/F实行PDMSAP型号代码委托型号代码承认BOM构成BOM生成I/FI/FTO-BEPROCESSProcessnameWorkCenterPROCESSNOPP-01-03ProductionPlanningdept.Remark1.光缆是CRP适用工作中心,COST反应工作中心区分.2.光纤工作单独不区分YesNo生产线变动事项发生出勤时间检验NewW/C生成变更与否Check?Factorycalendar检验Activitytype检验ChangeWorkCenterCostcenter检验TO-BEPROCESSProcessnameRoutingPROCESSNOPP-01-04ProductionPlanningdept.Remark1.光缆Routing构成时CRP适用工序和加工分配工序区分构成.ST输入方法-CRP适用工序:压缩工序ST输入-COST适用工序:全工序ST输入2.光纤与其它工序是CRP工序除外新规型号/A'ssy生成/变更代码是否在系统里存在?PP-01-03WorkCenter生成/变更Routing修整PP-01-01MaterialMaster生成/变更STCheckRouting生成Version&Quata生成WorkCenter是否存基础Routing是否存在?YNOYESYNONOTO-BEPROCESSProcessnameFactoryCalender(出勤日历)PROCESSNOPP-01-05ProductionPlanningdept.Remark1.FactoryCalender是年间calendar制作输入SAP里输入2.全月最后周别FactoryCalendar生产管理通报3.通报的差别FactoryCalendat是每月SAP里输入.法人管理科+生产管理科协商法人住员会议时确定SAPR/3反应TO-BEPROCESSProcessnameSOP(Sales&OperationPlanning)PR...