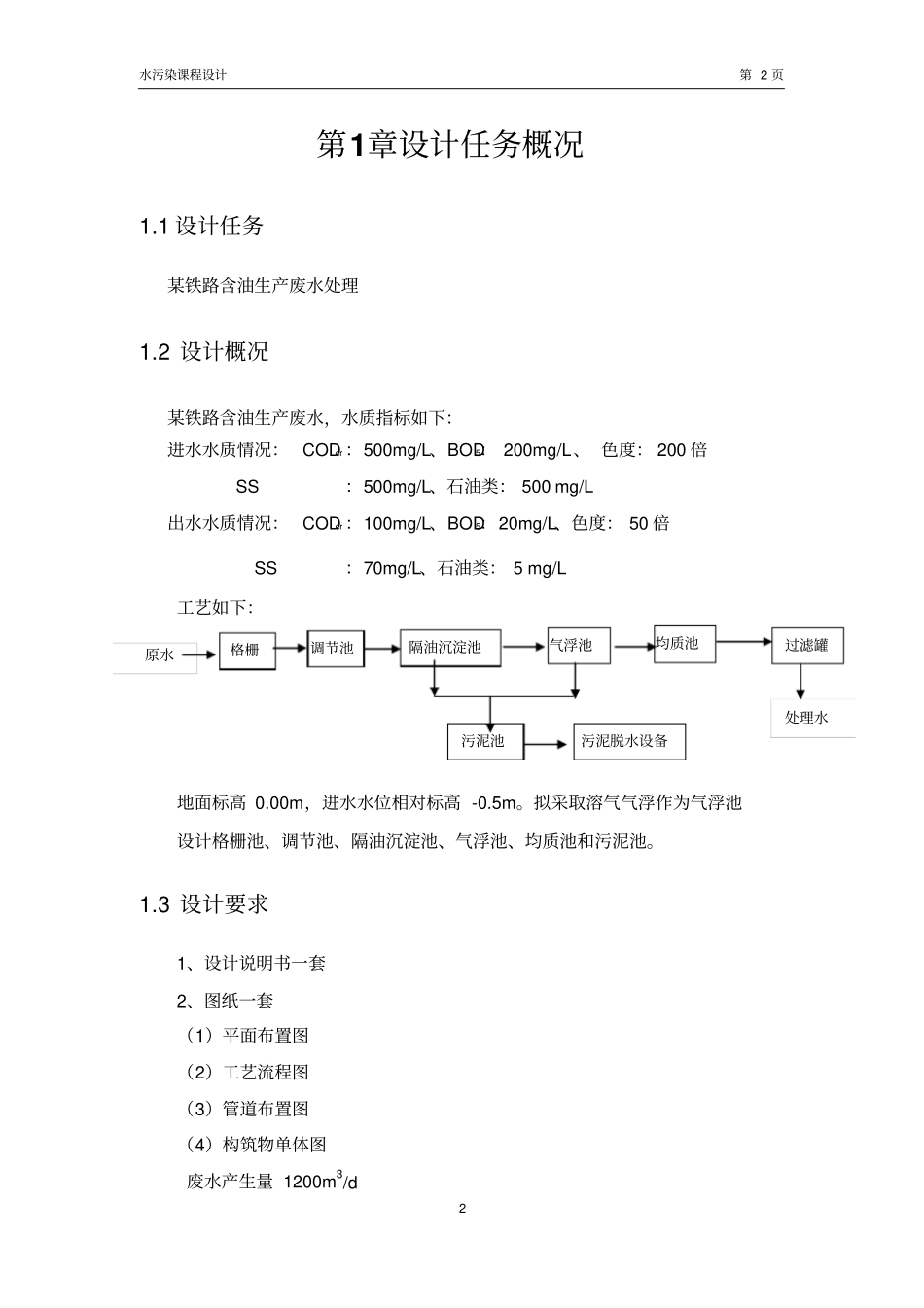

西南交通大学水污染课程设计题目:含油废水的处理学院:地球科学与环境工程学院专业:环境工程年级:2009级指导教师姓名:董海山设计人:孙立朋20094639冯柳阳20094640朱志勇20094642林鹏鹏20094643古丽君20094652魏清波20094653叶天一20094663完成日期:2012年7月13日水污染课程设计第1页1目录1设计任务及概况···································21.1设计任务·····································21.2设计概况·····································21.3设计要求·····································21.4铁路含油废水的特点、来源及危害·················31.5含油废水的初步处理与原理·····················51.6废水处理的原则·······························61.7含油废水处理流程·····························62主要构筑物的设计及选择··························82.1格栅········································82.2调节池·······································82.3潜污泵和管径的选择···························92.4隔油沉淀池···································112.5气浮池·······································132.6污泥池······································182.7均质池·······································192.8过滤罐·······································213总结············································22水污染课程设计第2页2第1章设计任务概况1.1设计任务某铁路含油生产废水处理1.2设计概况某铁路含油生产废水,水质指标如下:进水水质情况:CODcr:500mg/L、BOD5:200mg/L、色度:200倍SS:500mg/L、石油类:500mg/L出水水质情况:CODcr:100mg/L、BOD5:20mg/L、色度:50倍SS:70mg/L、石油类:5mg/L工艺如下:地面标高0.00m,进水水位相对标高-0.5m。拟采取溶气气浮作为气浮池设计格栅池、调节池、隔油沉淀池、气浮池、均质池和污泥池。1.3设计要求1、设计说明书一套2、图纸一套(1)平面布置图(2)工艺流程图(3)管道布置图(4)构筑物单体图废水产生量1200m3/d原水隔油沉淀池均质池过滤罐处理水格栅污泥池污泥脱水设备调节池气浮池水污染课程设计第3页31.4铁路含油废水的特点、来源及危害1.4.1含油废水来源目前铁路含油废水的处理及回用尚未普遍进行,而我国铁路机车车辆工厂、机务段、车辆段和洗罐站等单位是全路排放含油废水最为集中的单位,且排放量大,每年排放的大量生产废水主要以含油废水为主,是铁路废水治理的重点和难点。我国铁路下属有大量的机车、车辆检修企业,每年检修大量的铁路机车和车辆,在机车、车辆的检修过程中,须对机车、车辆清洗及对拆换下来的零配件进行蒸煮、清洗,因而产生大量含油废水。铁路检修企业所产生的含油废水的油类主要为废机械油、润滑油,含少量乳化油,废水中的主要污染物为石油类、COD、悬浮物等,水质变化幅度较大。铁路生产中产生的含油废水主要是机车车辆在检修过程中排放的,废水中主要污染物质是油,根据废水的性质和来源不同大致可以分为3类:(1)蒸汽机务段排放的含油废水:来自蒸汽机车检修和机车锅炉的清洗。(2)内燃机务段排放的含油废水:来自内燃机车定修、架修和零部件清洗。(3)车辆段排放的含油废水:主要来自车辆转向架的高压冲洗、油箱和零部件的煮洗。承担厂修任务的内燃和蒸汽机车厂排放的含油废水...