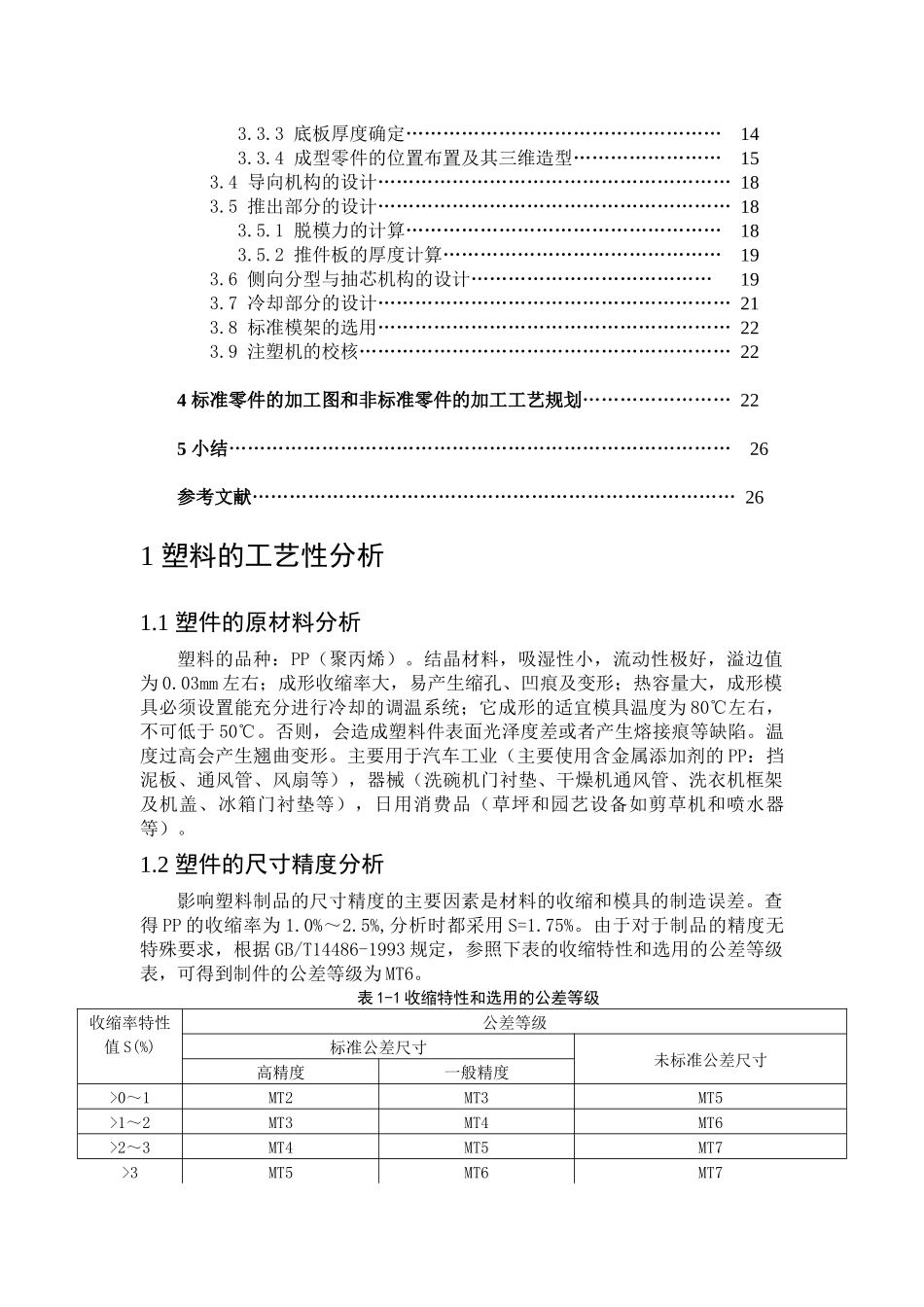

电风扇上盖注塑成型模具设计摘要:塑料注塑成型可以制作大量具有高精度和复杂型腔形状的制件。通过用注塑模 CAE 软件 MOLDFLOW 对塑件进行模流分析,选择聚丙烯的成型工艺参数 ,设计了一模一腔的注射模具。按聚丙烯的平均收缩率设计计算模具成型尺寸。分析了电风扇上盖的结构工艺特点,介绍了电风扇上盖注射模结构及模具的工作过程, 介绍了模具设计方案、工作原理, 阐述了成型部件、浇注系统凝料双层结构、顶出机构的设计特点。同时介绍了成型零件的加工制造的过程。关键字:注塑模;MOLDFLOW 分析;制造Design Of Injection Mould For Cover Of FanAbstract :The plastic injection molding is known to be the most effective process for producing discrete plastic parts of complex shape to the highest precision at a low cost.An injection die with a mold cavity was designed though using the injection mold CAE software MOLDFLOW to simulate plastic flow and choosing the molding parameters of polypropylene. The molding size was designed according to the average shrinkage ratio of polypropylene.Analyzing on the structural character of cover of fan, the structure of injection mold and the mold working process are introduced. The design specialities of molding parts,the double deck structure of concretionary plastic for the gating system and the ejection mechanism were presented as well.Meanwhile,manufacturing of the molding size were introduced.Keyword:Injection mould;Analyzing of MOLDFLOW;Manufacturing目 录中文摘要英文摘要1 塑料的工艺性分析……………………………………………………… 41.1 塑件的原材料分析……………………………………………… 41.2 塑件的尺寸精度分析…………………………………………… 41.3 塑件的表面质量分析…………………………………………… 41.4 塑件结构的工艺性分析………………………………………… 42 注塑过程的分析及确定成型设备选择………………………………… 52.1 注塑过程的分析………………………………………………… 52.2 选用注塑机……………………………...