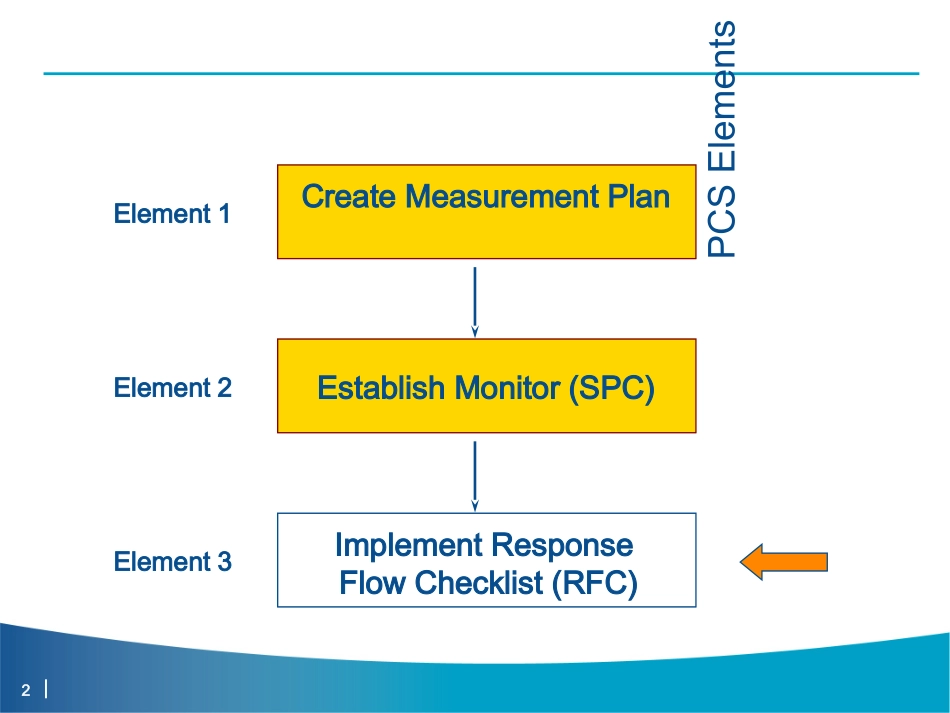

反应流程图ResponseFlowChecklist2PCSElementsCreateMeasurementPlanEstablishMonitor(SPC)ImplementResponseFlowChecklist(RFC)Element1Element2Element33ContentsIntroduction–WhatisanRFC?–BenefitsofUsinganRFC–WhenShouldanRFCbeUsed?DevelopinganRFCDocumentationofRFCResultsRFCStorageandRetentionRFCContinuousImprovementGuidelinesRFCExpectations4WhatisanRFC?Adocumenttocontainsuspectproductandreturntheprocess/equipmenttoaproductivestateasquicklyaspossible.Composedofdefinedsetoftasks(actionitems)tobeperformedinspecificorderRequirescertaindecisionstobemadetofindsolutiontotheproblemandthereforemayleadtotwoormoredifferentsolutionsdependingonthescenario.5START1)xxxx2)xxxx3)xxxx4)xxxxSTOPOK?“DIAGNOSIS”ACTIVITIESLISTOFALLPOSSIBLECAUSESOFINSTABILITY“REMEDY”ACTIVITIES“VERIFICATION”ACTIVITYRFCStructure”Diagnosis"activitiesareusedfirsttodeterminethecauseoftheprocessinstability.Foreachpossiblecause,thereisasetof"remedy"activitiesthatareusedtofixtheproblemoncethecausehasbeendetermined.”Verification"activityisthefinalstep.Itisperformedtomakesurethattheprocessproblemhasbeenfixed.6ExampleofanRFC(FlowchartType)ExposedCopperMonitoringRFCSpecxx-xxxxDecisionActionEndStartContinueFormRevACRevDate:12/20/97Page1of1MS/MT/OperatorTechnicianMfgSupervisorTop-up/DilutechemicalperShiftEngr.instructionanddocumentitinchemicalanalysisrecordingbookCheckDeflashandDescaleconcentrationYesWithinspecwindow?NoCheck1)Deflashrectifier2)Titaniumanodeplate3)OilcontaminationinHPtank4)Excessivemold/resinbleedoutVerifywithdummyNoDocumentitandinformShiftsupt.YesExposedcopper?YesNoRectifytheproblemaccordingly&documentitinrecordingbookWithinspecwindow?InformProc./Equip.EngineerVerifywithdummyNoDocumentitandinformShiftsupt.YesExposecopper?ExposedcopperYesWithinspecwindow?NoAAABBUpdateon-holdlotsinshiftlyreportLastBlock:Enggactions/comments:_____________________-_________________________________________EndorseRFCtoMfgforfiling.7BenefitsofUsinganRFCIdentifiescauseofprocessorequipmentfailures–ControlchartsandSPCtrendrulestellusonlywhentheprocessisout-of-control,notwhyitisout-of-control.Theycannottelluswhattodotofixtheproblem,either.Forthat,weneedtheRFC.LeadsMfgTechnician/SpecialistthroughstepsinsolvingtheprobleminthequickestpossibletimeMinimalneedforEngineeringinvolvementDocumentsproblemcauseandresolutionhistory8WhenShouldanRFCbeCreated?Statisticalprocesscontrol–Whenanout-of-control(OOC)conditionoccurredProductqualityandyieldcontrol–Whenquestionableproductsaredetectedatanystation–WhenlowyieldinglotsareseenatanystationProcess/Equipmentfailure–Forrestoringamachinetoproductionafterithasbeenshutdownduetoaprocess/equipmentrelatedfailure9PCSSPCProcess/EquipmentmaintenanceandcontrolsProductQualityandYieldRFCViolations?e.g.,out-of-control(OOC)pointsLowyieldordiscrepantmaterials?(i.e.,lessthandefined/agreedgoals)Failures?e.g.,missingunits,process/equipmentmonitorproblemssuchasballshearfailure,temperatureproblems,etc.FMEARFCModel10WhoDevelopstheRFC?Initiatedandledbytheprocessorequipmentowner(e.g.,ModuleEngineer)inateamenvironmentRFCDevelopmentTeamshouldincludethefollowing:–Process/EquipmentEngineers–ProductEngineers–Q&REngineers–MaintenanceTechnicians–ManufacturingpersonnelShiftManagers,MfgSupervisors,MS/MT/Operator–Statisticians–Contentexperts11ContinuousimprovementPublishtheRFCD...