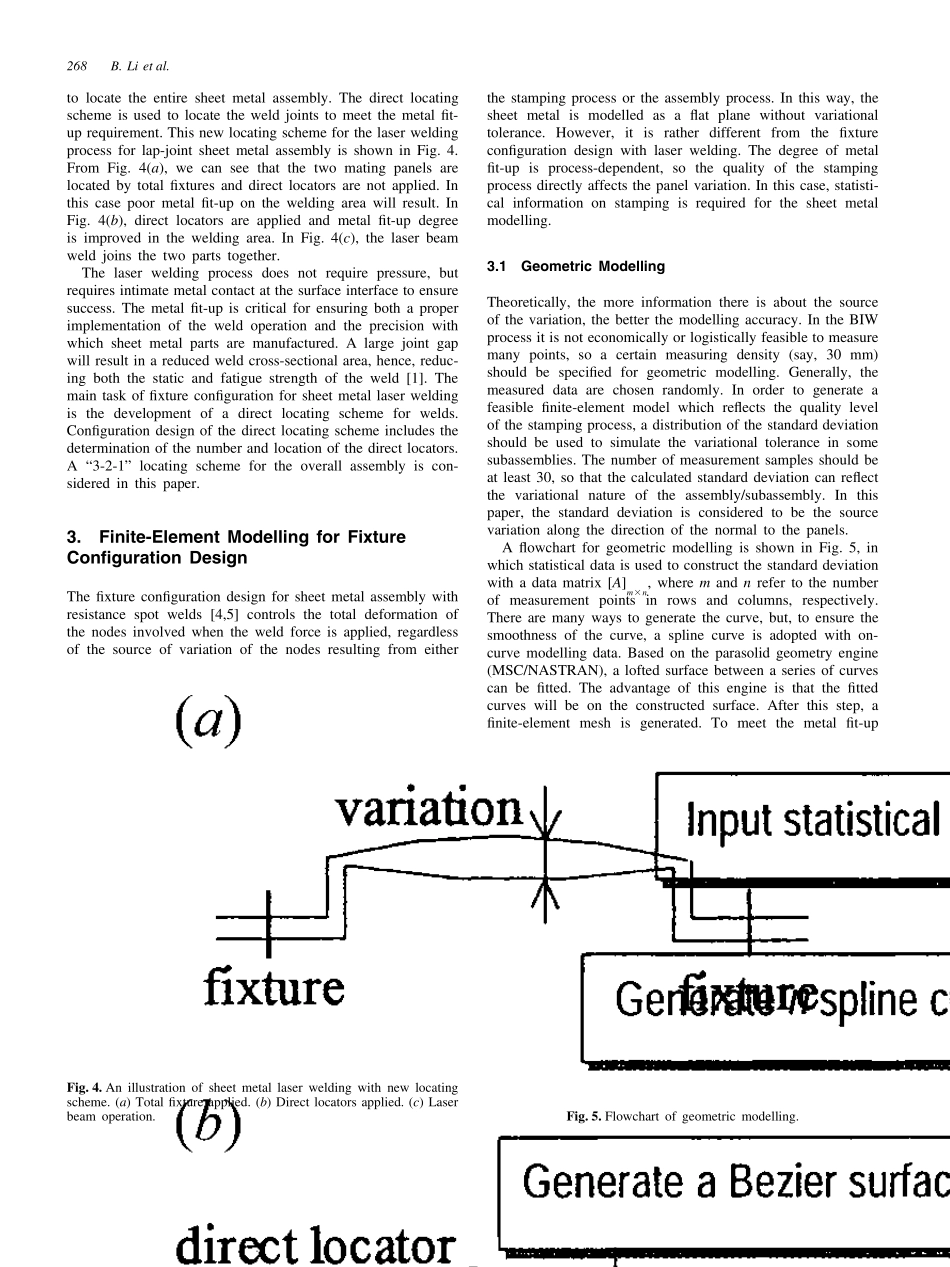

Int J Adv Manuf Technol (2001) 18:266–275 2001 Springer-Verlag London LimitedPrinciple and Simulation of Fixture Configuration Design forSheet Metal Assembly with Laser Welding. Part 1: Finite-ElementModelling and a Prediction and Correction MethodB. Li, B. W. Shiu and K. J. LauDepartment of Mechanical Engineering, Hong Kong Polytechnic University, Kowloon, Hong KongThe quality of the stamping process has a direct effect onlaser welded sheet metal assembly. The fixture plays animportant role in the satisfactory metal fit-up that laser weldingrequires. The traditional “3-2-1” locating scheme will nolonger suffice for the deformable laser sheet metal assemblyprocess. Because of the often poor stamping quality, a complexdie fixture has to be employed to meet the metal fit-up require-ments. The die fixture corresponds to an “infinite-2-1” locatingscheme where the tooling cost is very high and yet lacksflexibility. This limits the application of laser welding. In thispaper, a new locating scheme with both total locating anddirect locating for welds is proposed. A total locating schemeis used to locate the overall assembly, and a direct locatingscheme is used to locate the weld location, which is criticalfor ensuring correct metal fit-up. A finite-element model anda prediction and correction method for the direct locatorconfiguration are developed in this paper. A case study is usedto show that the proposed method is effective for sheet metalassembly for laser welding.Keywords: Fixture configuration design; Laser welding; Locat-ing scheme; Sheet metal assembly1.IntroductionThe process of automotive body assembly involves joiningsheetmetalcomponents to form abody-in-white (BIW)assembly. Welding contributes to much of the ass...