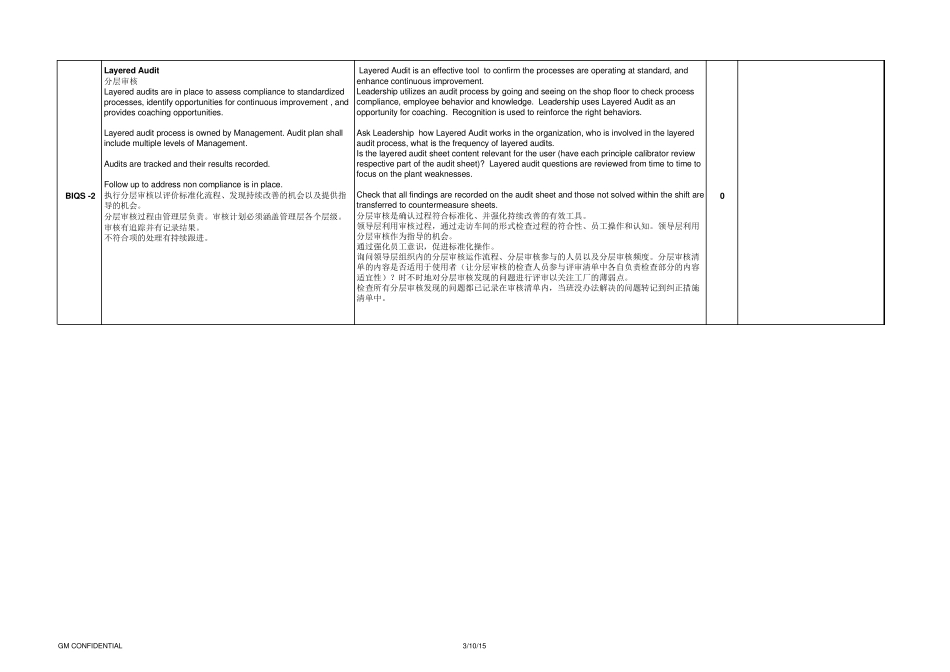

BIQSItem #BIQS RequirementBIQS Calibrator Guidelines (Look For)ScoreCommentsBIQS -1Nonconforming Material / Material Identification不合格物料/物料标识Team members have standardized work and understand what to dowith non conforming / suspect material.Conforming material is handled, stored and identified appropriately.Non conforming / suspect material is clearly identified and/orsegregated for review/disposition (i.e. appropriate color coding forfoot printing – red, yellow, green).A containment method is in place to ensure that an effectivebreakpoint has been established. Containment activities andresults are documented.Traceability is applied according to the traceability methods of thefinished product.团队成员有标准作业指导书指导作业,并清楚如何处理不合格/可疑物料。确认物料处理、存储、标识得当。清楚标识不合格/可疑物料,并隔离处置。(即:使用合适的颜色对地面进行标识-红、黄、绿)已定义围堵方法以确保建立了有效的断点。围堵活动及结果都有形成书面记录。根据成品的追溯方式应用追溯性。Sample audit to verify that team members understand what to do with nonconforming /suspect material.Confirm that conforming material is handled, stored and identified appropriately.Confirm that nonconforming / suspect material is clearly identified and/or segregated. Red,Yellow, Green stoplight approach is adhered to for foot printing, containerization, tablemarking and tagging.Audit that all parts removed from the process are identified, accounted for (FTQ), andreconciled to eliminate mishandling of material.Verify use of Department Containment Worksheets, with potential parts locations by operationidentified to ensure no parts are missed during a containment and all parts are reconciled.The containment worksheets must cover from the incoming material, process and shipment.Scrap or Suspect parts/containers cl...