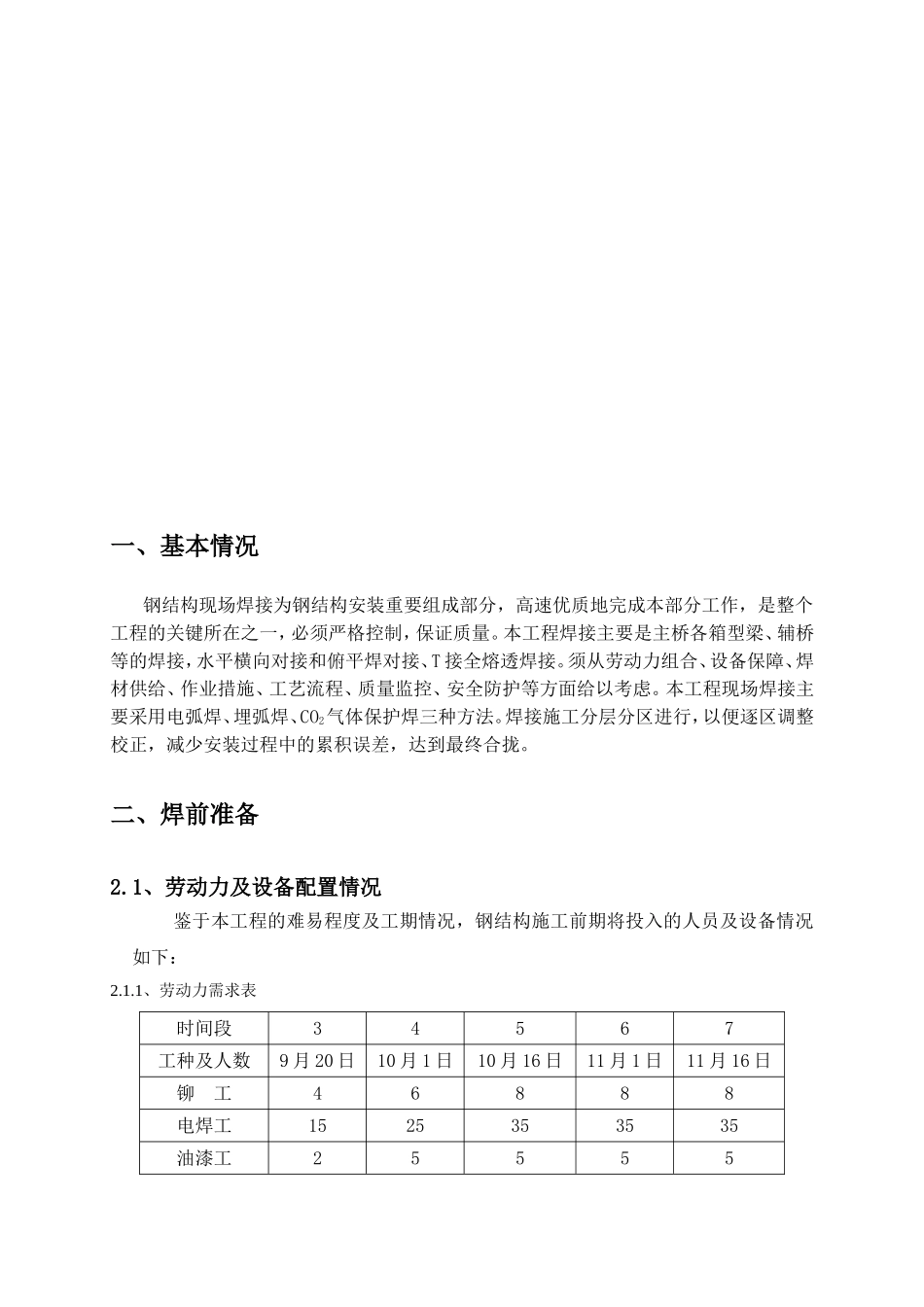

目录一、基本情况................................................3二、焊前准备..............................................32.1、劳动力及设备配置情况.......................................32.2、焊接工艺评定...............................................5三、焊接环境...............................................63.1、焊接防护....................................................63.2、焊接防护措施..............................................6四、焊接工艺流程............................................9五、焊接工艺...............................................105.1、钢箱梁现场焊接的主要焊缝...................................105.2、焊接原则...................................................105.3、焊接顺序及方法.............................................105.4、焊接方法....................................................11六、焊接检验..............................................136.1、焊缝检验范围...............................................136.2、焊缝检验标准...............................................13七、计划的保证措施........................................147.1、质量控制程序..............................................157.2、质量措施.................................................167.3、组织措施..................................................177.4、制度措施..................................................187.5、技术措施..................................................187.6、经济措施..................................................187.7、安全措施...................................................18八、冬、雨季施工安排及施工措施.................................198.1、冬季焊接施工..............................................198.2、雨季施工措施...............................................21九、安全施工保证措施.............................................22十、焊接过程中应急预案......................................2310.1、应急预案..................................................2310.2、各项事故的处理方法........................................2410.3、事故应急简单急救方法.....................................26一、基本情况钢结构现场焊接为钢结构安装重要组成部分,高速优质地完成本部分工作,是整个工程的关键所在之一,必须严格控制,保证质量。本工程焊接主要是主桥各箱型梁、辅桥等的焊接,水平横向对接和俯平焊对接、T接全熔透焊接。须从劳动力组合、设备保障、焊材供给、作业措施、工艺流程、质量监控、安全防护等方面给以考虑。本工程现场焊接主要采用电弧焊、埋弧焊、CO2气体保护焊三种方法。焊接施...