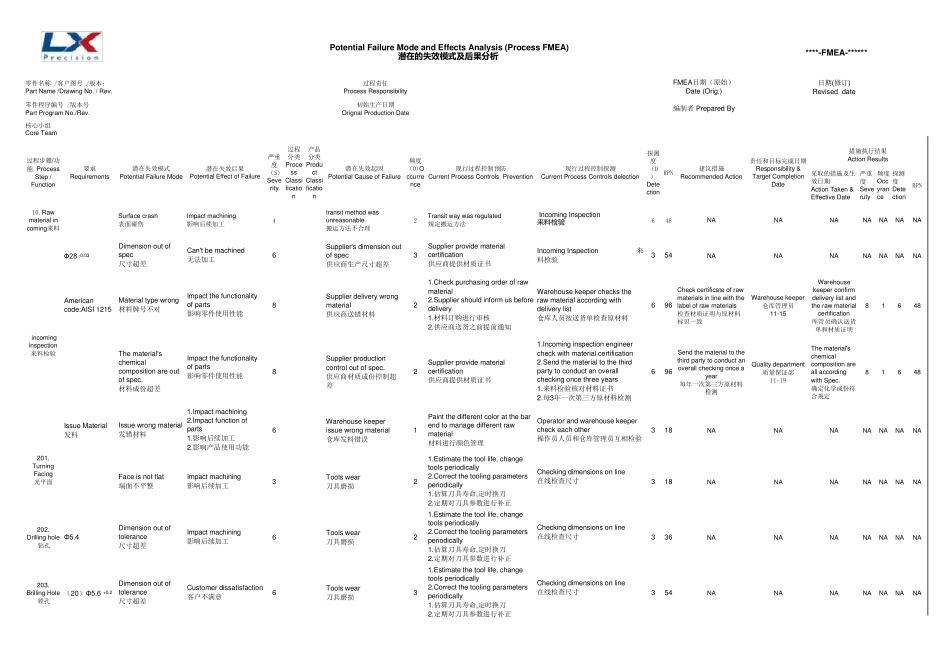

日期(修订)Revised date采取的措施及生效日期Action Taken &Effective Date严重度Severuty频度Occyrance探测度DetectionRPN10.Rawmaterial incoming来料4transit method wasunreasonable搬运方法不合理2648NANANANANANANAФ28 -0.036Supplier's dimension outof spec供应商生产尺寸超差3354NANANANANANANAAmericancode:AISI 12158Supplier delivery wrongmaterial供应商送错材料2696Check certificate of rawmaterials in line with thelabel of raw materials检查材质证明与原材料标识一致Warehouse keeper仓库管理员11-15Warehousekeeper confirmdelivery list andthe raw materialcertification库管员确认送货单和材质证明816488Supplier productioncontrol out of spec.供应商材质成份控制超差2696Send the material to thethird party to conduct anoverall checking once ayear每年一次第三方原材料检测Quality department质量保证部11-19The material'schemicalcomposition areall accordingwith Spec.确定化学成份符合规定81648Issue Material发料6Warehouse keeperissue wrong material仓库发料错误1318NANANANANANANA201.TurningFacing光平面3Tools wear刀具磨损2318NANANANANANANA202.Drilling hole 钻孔Φ5.46Tools wear刀具磨损2336NANANANANANANA203.Brilling Hole 镗孔(20)Φ5.6 +0.26Tools wear刀具磨损3354NANANANANANANACan't be machined无法加工Impact the functionalityof parts影响零件使用性能Impact the functionalityof parts影响零件使用性能1.Impact machining2.Impact function ofparts1.影响后续加工2.影响产品使用功能Impact machining影响后续加工Impact machining影响后续加工Customer dissatisfaction客户不满意Supplier provide materialcertification供应商提供材质证书1.Check purchasing order of rawmaterial2.Supplier should inform us beforedelivery1.材料订购进行审核2.供应商送货之前提前通知Supplier provide materialcertification供应商提供材质证书Paint the different color at the barend to manage different rawmaterial材料进行颜色管理1.Estimate the tool life, changetools periodically2.Correct the tooling parametersperiodically1.估算刀具寿命,定时换刀2.定期对刀具...