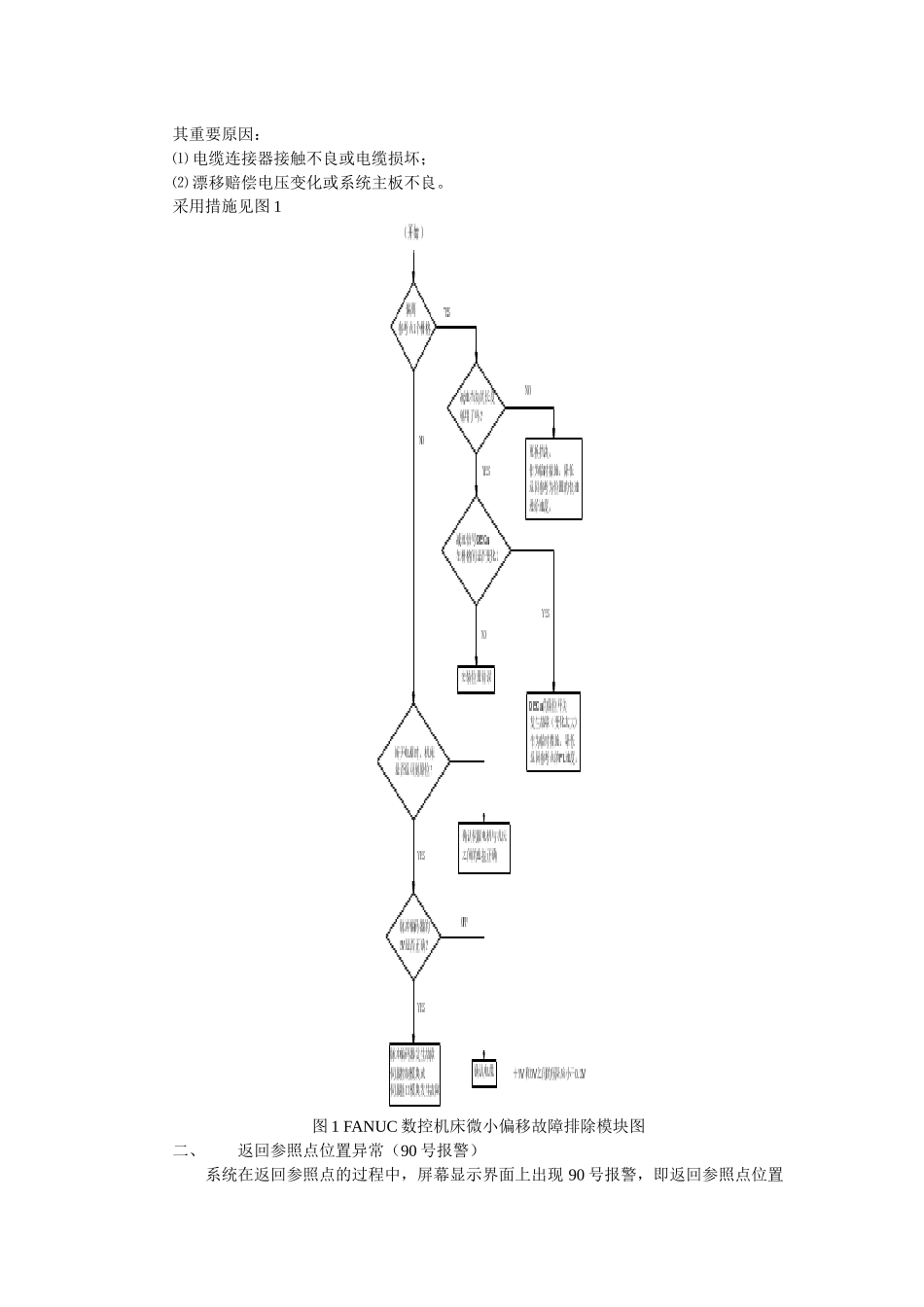

FANUC 数控机床不能返回参照点的故障处理许光磊 高来明(河北能源职业技术学院,河北 唐山 063004)摘要:FANUC 数控机床是高性能机电一体化产品,其位置检测用的是串行脉冲编码器,由于串行脉冲编码器的特点,机床在开机和急停的状况下,都要执行返回参照点的操作。就是让机床坐标轴移动到一种预先制定的精确位置,如不能返回参照点,数控机床将不能正常工作。关键词:数控机床,参照点,编码器FANUC-OTD Numerical control machine tool can not return to referencepoint recovery processingXu Guanglei (The Department of Mechanical and Electrical Engineering, Hebei Polytechnic College of Energy Resources, Hebei, Tangshan, 063004)Abstract: FANUC-OTD numerical control machine tool is a high-performance integration of machinery with electronics product , whose location checks the serial pulse coder with being, since stringing the characteristic doing a pulse coder together, the machine tool all needs to carry out the operation returning to the reference point under the situation of starting up and staying urgently. Be to let the machine tool coordinate axis move the accurate location working out in advance to one, if being able to not return to the reference point, numerical control machine tool will can not work regularly.Keywords: Numerical control machine tool , reference point , coder数控机床是高性能机电一体化设备,FANUC-OTD 数控机床在开机、断电、急停的状况下,需要机床返回参照点。参照点是机床坐标轴需要移动到一种预先指定的精确位置这一位置成为机床的参照点,执行回参照点操作是为了建立机床坐标系。机床通电后刀具的位置是随机的,因此 CRT 显示的坐标值也是随机的 ,必须进行手动返回参照点的操作,系统才能捕捉到刀具的位置,然后机床才能转入正常工作。机床不能返回参照点是数控机床的常见故障。一、FANUC-OTD 数控机床不能返回参照点的常见原因如下:1、 刀具偏离参照点一种栅格的距离。⑴ 参照点减速挡块位置不对的;⑵ 参照点减速挡块的长度太短;⑶ 参照点用的靠近开关位置不妥;该故障一...