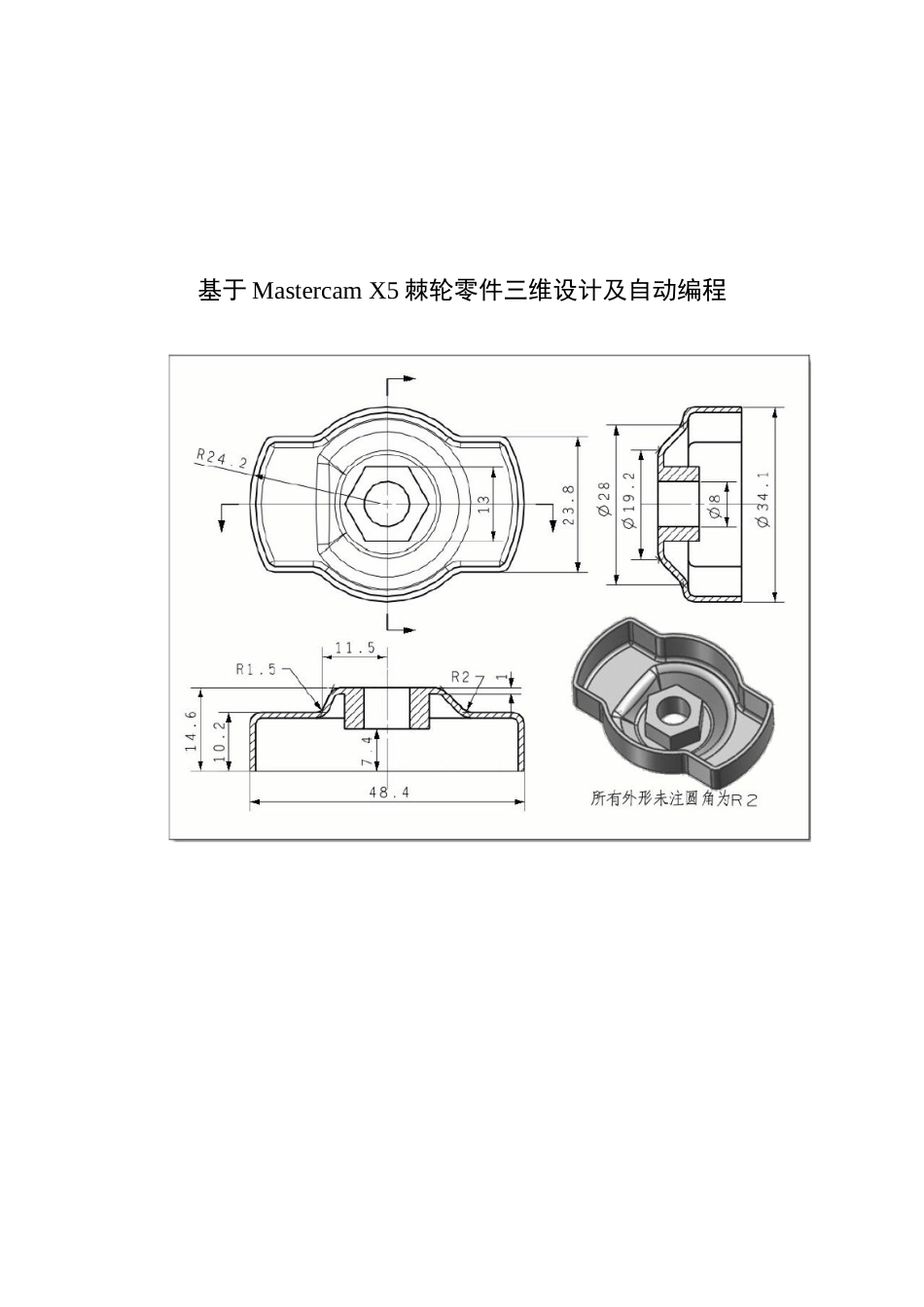

基于 Mastercam X5 棘轮零件三维设计及自动编程【摘要】本文主要阐述棘轮零件的三维造型及数控加工,内容包括零件图的工艺分析、工件的装夹方案、零件的加工工艺分析、工艺流程、程序设计等,其中零件图的工艺分析包括零件图的完整性及正确性、材料、技术要求、结构工艺性等方面的分析;装夹方案包括毛坯的选择、机床的选择、夹具的选择;加工工艺分析包括加工顺序的安排、刀具的选择、切削用量的选择等等。这些都是零件加工的重要组成部分,要使零件的加工精度,效率得到提高,就必须先对零件进行分析,确定好正确的工艺流程,使用 Mastercam 软件对零件进行三维造型和数控加工,充分发挥数控机床的高精度,高效率的特性。关键词: 工艺分析、装夹方案、工艺流程、三维造型、自动编程Abstract: This paper mainly discusses the 3D modeling and NC machining of ratchet parts, including parts of the process analysis, workpiece clamping scheme, parts of the process analysis, process, program design, the process of parts drawing analysis includes parts of the integrity and correctness, materials, technical requirements, construction technology and so on; the clamping scheme includes the choice of blank, the choice of machine tools, jig choice; analysis of the technological process including the sequencing of machining, tool selection, cutting the amount of choice etc.. These are an important part of machining, the machining accuracy of parts, improve the efficiency, we must first on the parts for analysis, determine the correct process, 3D modeling and NC machining of parts using the Mastercam software, give full play to the high accuracy of numerical control machine, high efficiency characteristics.Key words: Process analysis, clamping scheme, process flow, three-dimensional modeling, automatic programming目 录1 绪论.........................................................................................................................................................41.1 ...