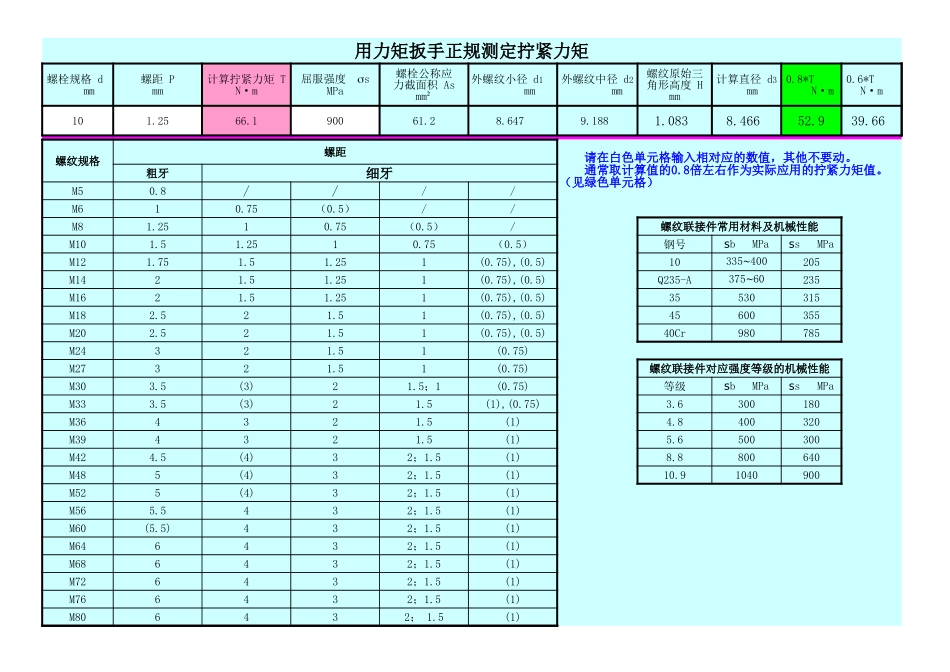

用力矩扳手正规测定拧紧力矩101.2566.190061.28.6479.1881.0838.46652.939.66螺纹规格螺距粗牙细牙M50.8////M610.75//M81.2510.75/螺纹联接件常用材料及机械性能M101.51.2510.75钢号M121.751.51.251(0.75),(0.5)10205M1421.51.251(0.75),(0.5)Q235-A235M1621.51.251(0.75),(0.5)35530315M182.521.51(0.75),(0.5)45600355M202.521.51(0.75),(0.5)40Cr980785M24321.51(0.75)M27321.51(0.75)螺纹联接件对应强度等级的机械性能M303.5(3)2(0.75)等级M333.5(3)21.5(1),(0.75)3.6300180M364321.5(1)4.8400320M394321.5(1)5.6500300M424.5(4)3(1)8.8800640M485(4)3(1)10.91040900M525(4)3(1)M565.543(1)M60(5.5)43(1)M64643(1)M68643(1)M72643(1)M76643(1)M80643(1)螺栓规格dmm螺距Pmm计算拧紧力矩TN·m屈服强度ssMPa螺栓公称应力截面积Asmm²外螺纹小径d1mm外螺纹中径d2mm螺纹原始三角形高度Hmm计算直径d3mm0.8*TN·m0.6*TN·m请在白色单元格输入相对应的数值,其他不要动。通常取计算值的0.8倍左右作为实际应用的拧紧力矩值。(见绿色单元格)(0.5)(0.5)(0.5)sbMPassMPa335~400375~601.5;1sbMPassMPa2;1.52;1.52;1.52;1.52;1.52;1.52;1.52;1.52;1.52;1.5