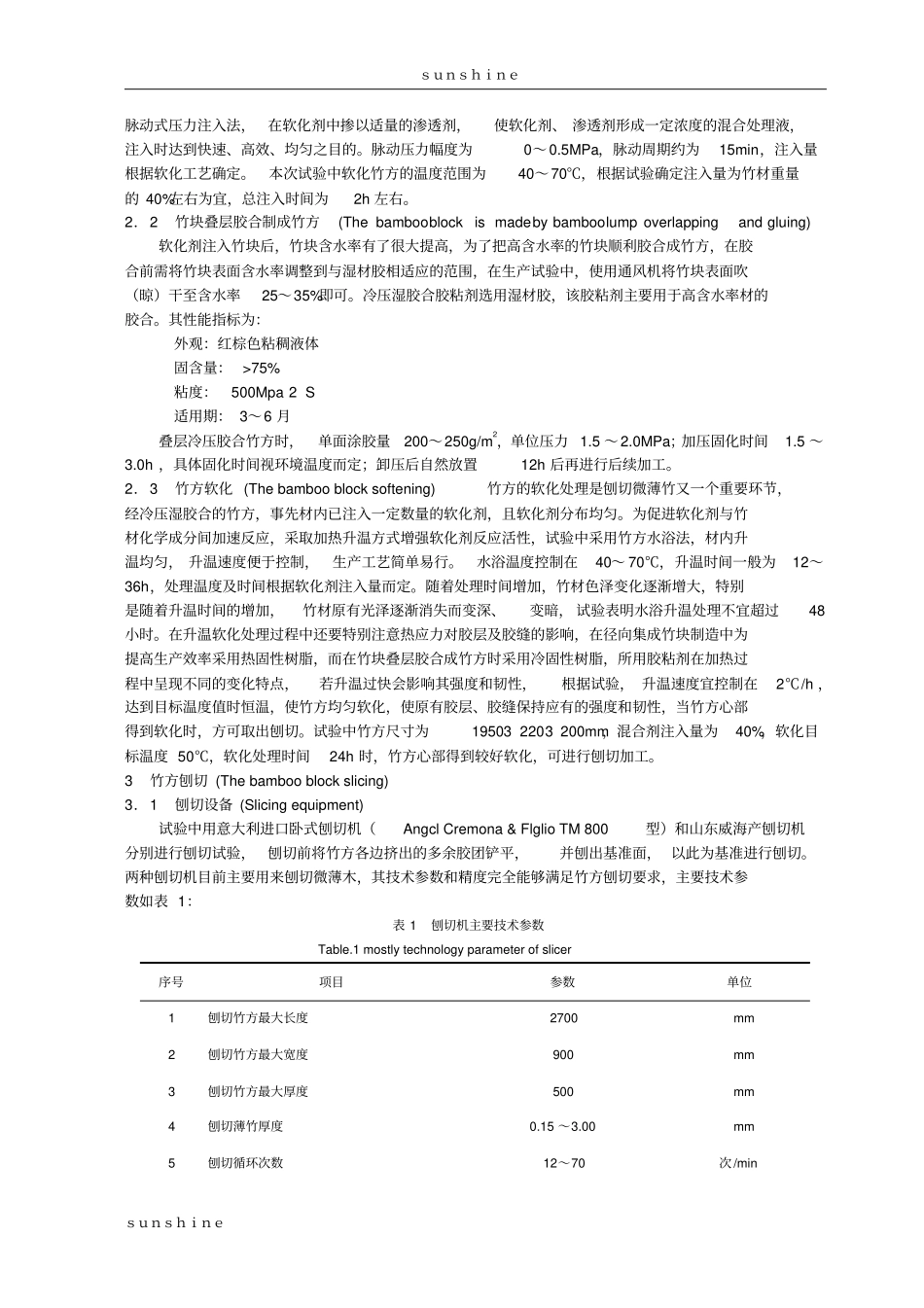

sunshinesunshine刨 切 薄 竹 生 产 工 艺 研 究刘志坤1 李延军1 杜春贵1 文桂峰1 林勇2( 1. 浙江林学院工程学院,浙江临安,311300 ; 2.杭州木材厂 . 浙江杭州 .310009; )摘要: 为提高竹材产品的科技含量和附加值,提高资源的利用效率,将毛竹横截、纵锯、粗刨、蒸煮、干燥等工序加工成矩形断面的竹条;再经精刨、 砂光、 涂胶、 侧拼制成侧拼单层竹片胶合板块;之后注入软化剂、竹块叠层湿胶合制得竹方;将竹方升温软化处理,在刨切机上刨切获得0.20 ~1.50mm,柔韧性良好,厚度均匀的刨切薄竹片,为竹材精、深加工和高效利用开辟了工业化利用新途径。刨切薄竹片可代替广泛使用的珍贵薄木用于装饰材料的贴面和家具表面装饰。关键词 :竹材加工、刨切、薄竹片、软化、竹方、胶粘剂中图分类号:A Study on Production Technology of Sliced Bamboo Veneer Liu Zhi-kun1Li Yan-jun 1 Du Chun-gui1Wen Gui-feng1 Lin Yong2 (1. Zhejiang Forestry College, Lian Zhenjiang 311300 ; 2 Hangzhou Wood factory . Hangzhou Zhenjiang. 310009)Abstract: A technology of sliced bamboo veneer is introduced. Bamboo is processed via cross cutting, rip saw, primary slicing, steaming, drying and so on planning into rectangle side bamboo strips, The strips are turned to bamboo plate plywood via smoothing slice ,sanding, glue application, increase the bamboo block ’s temperature to intenerate it. After the block is processed to the even-thickness(about 0.20~1.50mm)sliced bamboo veneer with high tenacity which may be used as the finely veneer for overlaying. This technology breaks a new path for the advanced industrialized process and usage of bamboo. Key Word: Bamboo Process ,Slice, Bamboo Veneer , Softening, Bamboo Block, Adhesive 我国是一个木材资源相对贫乏,特别是优质大径阔叶材短缺,而竹材资源较丰富的国家。较长时间以来木材资源一直存在着供需紧张的矛盾,尤其是国家实施“天然林保护工程”后,这种矛盾就变得更加突出,森林资源开发利用的重点已由天然林逐步转变为速生人工林为主,因此竹...