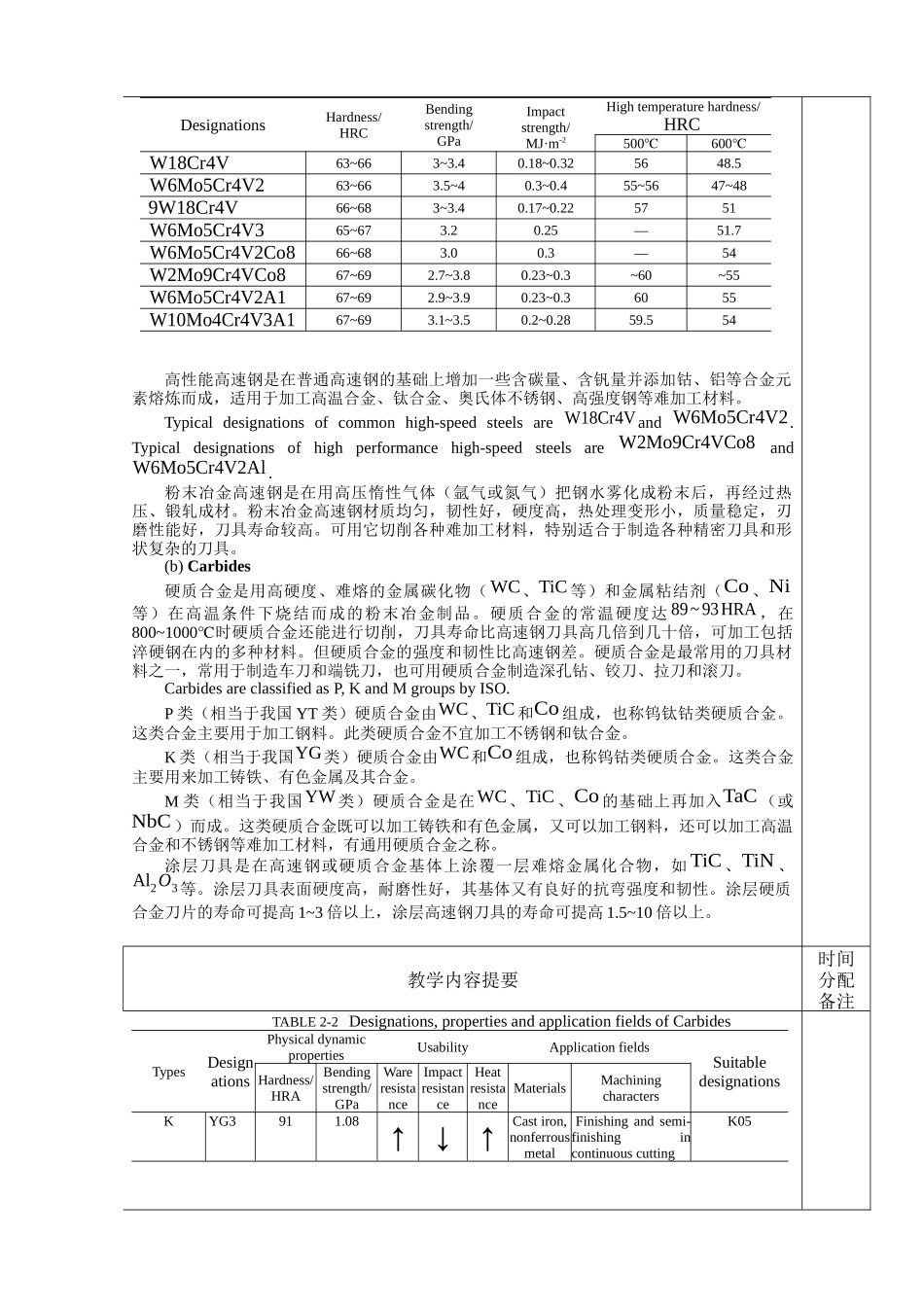

教 案 4课程名称:机械制造技术基础 双语 A 授课教师谭庆昌所在单位机械学院机械制造系课程类别课堂理论教学授课时间07~08 学年 2 学期 2 周授课内容2 Cutting Processes and their Control2.1 Basic Theory of Cutting-tool 2.2 Deformation during the cutting process授课对象机械工程、车辆工程、农业机械、汽运工程、交通工程专业本科生教学内容提要时间分配备注(b)Influence of the tool mounting position on working anglesWhen the tool tip is higher or lower than the axis of the workpiece, the working rake angle and relief angle will change.以图 2-11 为例,如果刀尖安装得高于工件中心,实际工作前角γ oe 将大于标注前角γ o ,工作后角α oe 将小于标注后角α o 。如果刀尖安装低于工件中心,则恰好相反。When the mean line of the tool holder is not perpendicular to the feed direction, the working cutting-edge angleκr and the minor cutting-edge angleκrˊ. will change (Figure2.12) .2.1.3Cutting-tool MaterialsA cutting-tool must have certain characteristics in order to produce good-quality and economical parts.1. Certain characteristics that a cutting-tool must have(a)High hardness and wearresistance (b)Enough strength and toughness(c)High heat resistance(d)Good heat conductivity and thermal shock resistance(e)Good processability2. Cutting-tool materials most in use(a) High-speed steels高速钢是加入了较多的钨(W )、钼(Mo )、铬(Cr )、钒(V )等合金元素的高合金工具钢。高速钢具有较高的硬度(62~67HRC)和耐热性,在切削温度高达500~650℃时仍能进行切削;高速钢的强度高、韧性好,可在有冲击、振动的场合应用;它可以用于加工有色金属、教学内容提要10 分钟5 分钟20 分钟时间分配备注结构钢、铸铁、高温合金等范围广泛的材料。高速钢的制造工艺性好。高速钢按切削性能可分为普通高速钢和高性能高速钢;按制造工艺方法可分为熔炼高速钢和粉末冶金高速钢。普通高速钢是切削硬度在250~280HBS以下的大部分结构钢和铸铁的基本刀具材料。TABLE 2-1 Typical properties of High-speed steel...