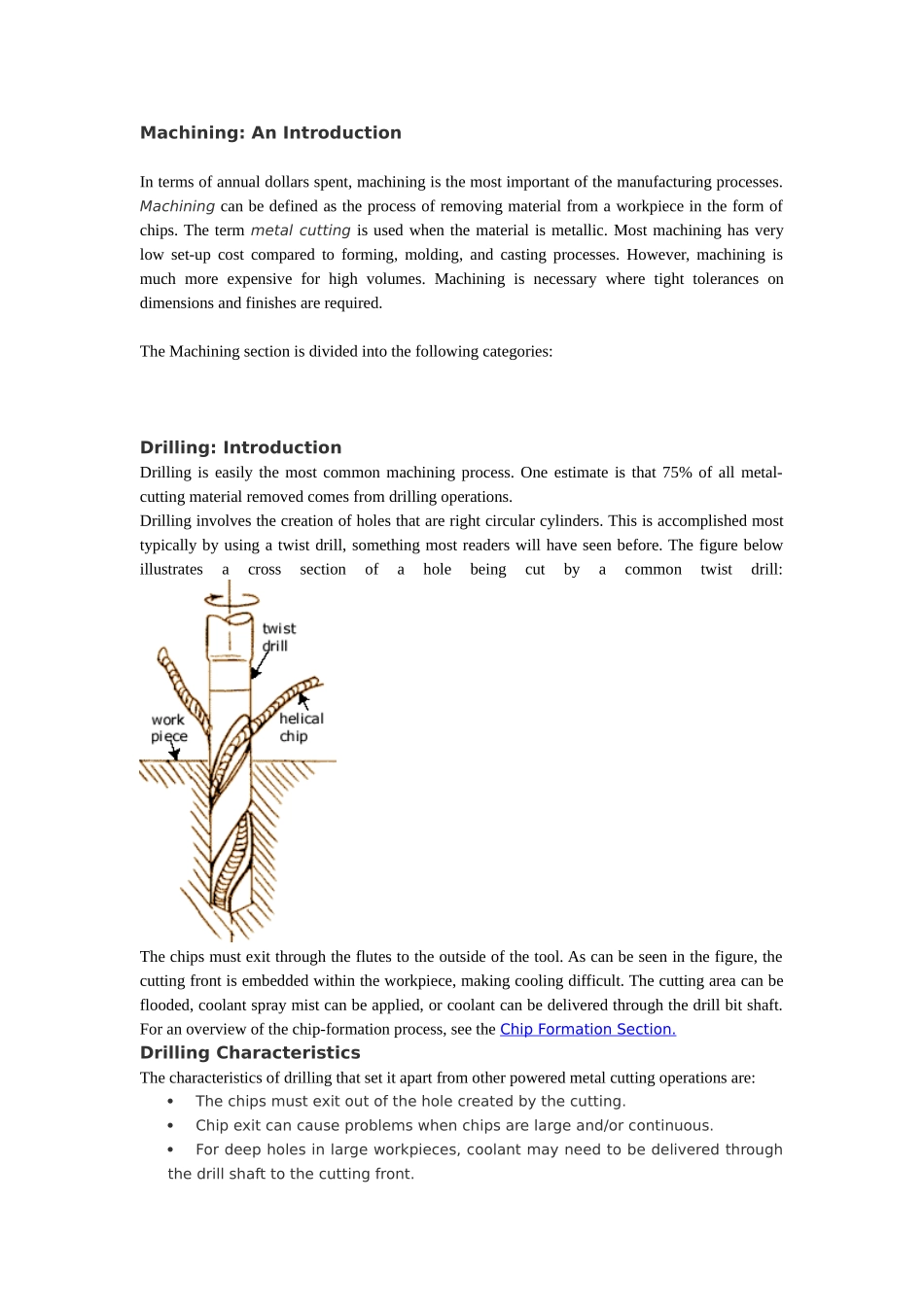

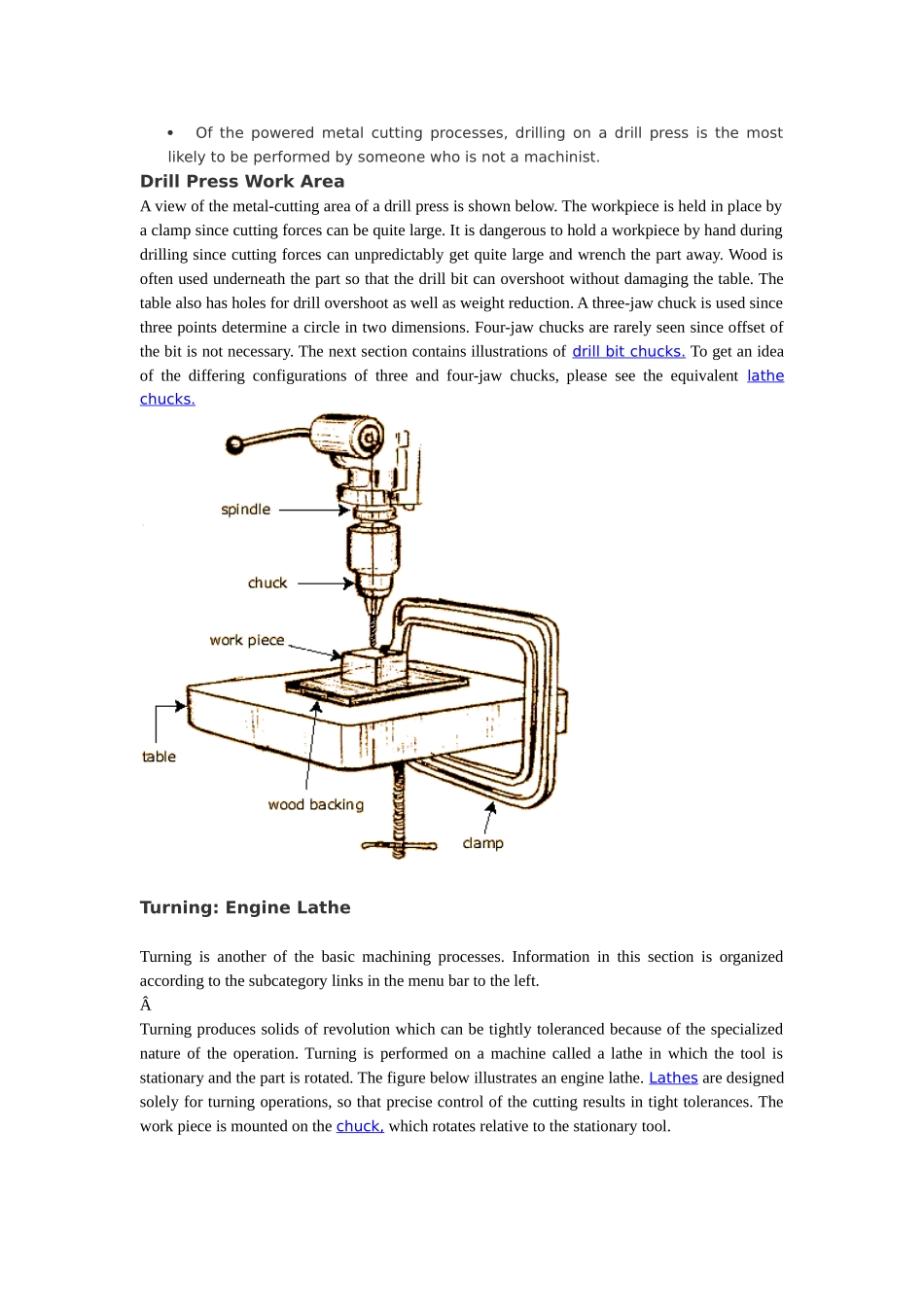

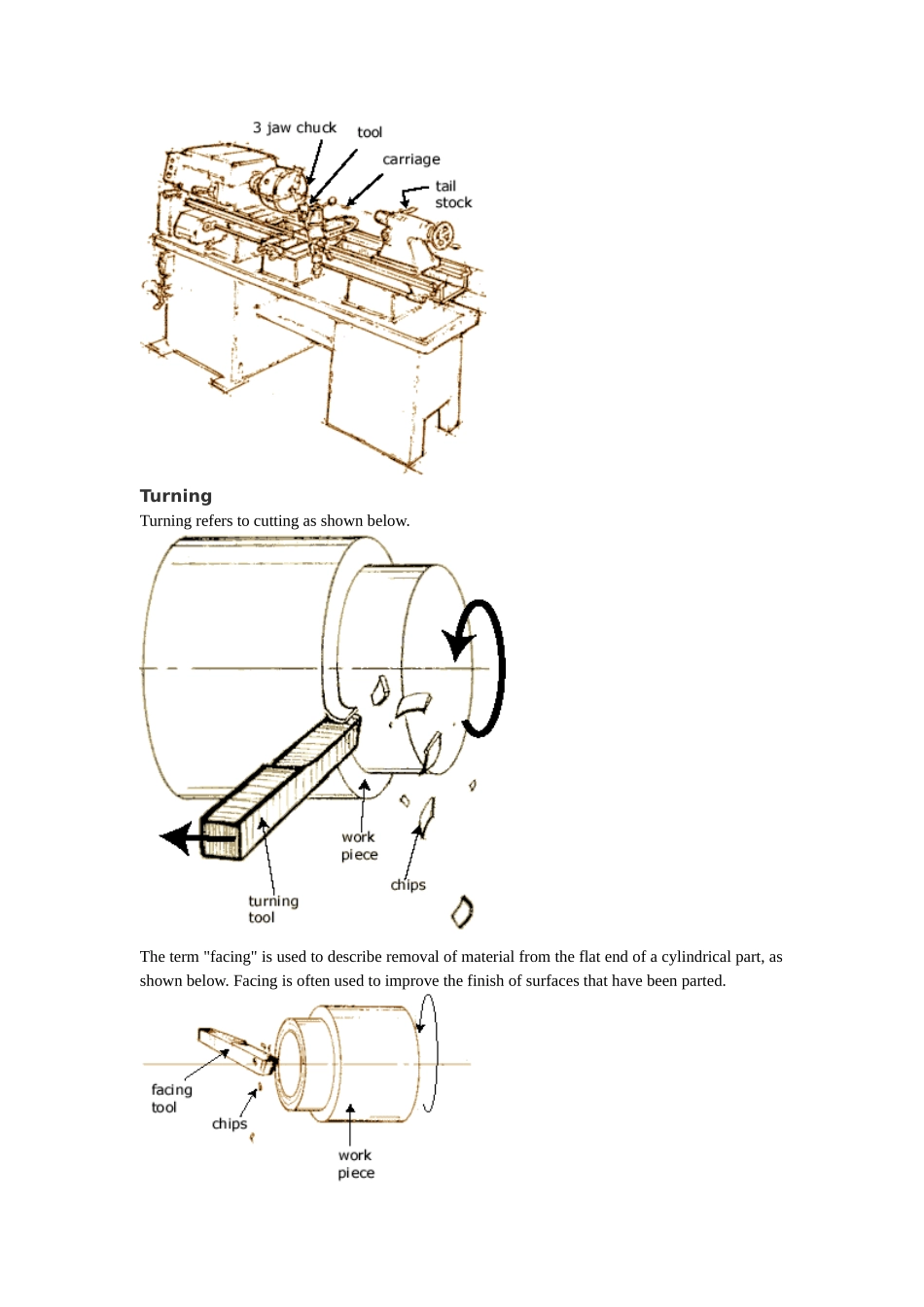

Machining: An IntroductionIn terms of annual dollars spent, machining is the most important of the manufacturing processes. Machining can be defined as the process of removing material from a workpiece in the form of chips. The term metal cutting is used when the material is metallic. Most machining has very low set-up cost compared to forming, molding, and casting processes. However, machining is much more expensive for high volumes. Machining is necessary where tight tolerances on dimensions and finishes are required. The Machining section is divided into the following categories: Drilling: IntroductionDrilling is easily the most common machining process. One estimate is that 75% of all metal-cutting material removed comes from drilling operations.Drilling involves the creation of holes that are right circular cylinders. This is accomplished most typically by using a twist drill, something most readers will have seen before. The figure below illustrates a cross section of a hole being cut by a common twist drill:The chips must exit through the flutes to the outside of the tool. As can be seen in the figure, the cutting front is embedded within the workpiece, making cooling difficult. The cutting area can be flooded, coolant spray mist can be applied, or coolant can be delivered through the drill bit shaft. For an overview of the chip-formation process, see the Chip Formation Section.Drilling CharacteristicsThe characteristics of drilling that set it apart from other powered metal cutting operations are: The chips must exit out of the hole created by the cutting.Chip exit can cause problems when chips are large and/or continuous.For deep holes in large workpieces, coolant may need to be delive...