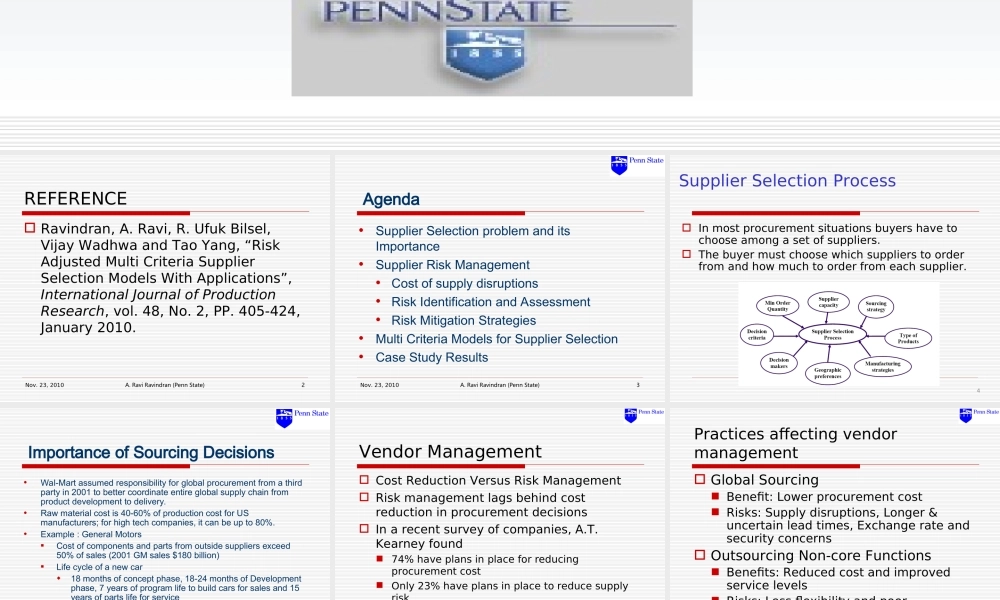

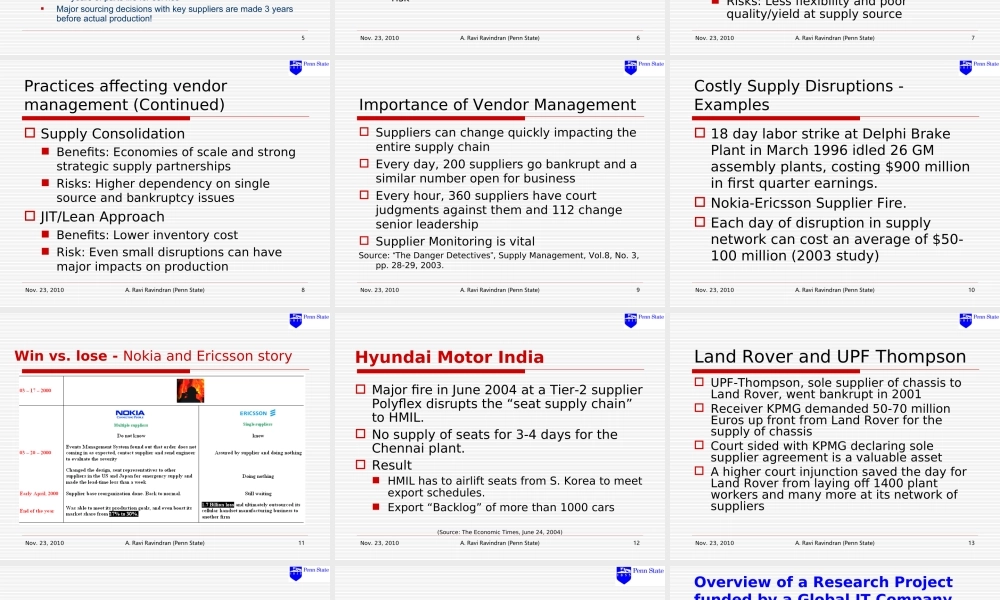

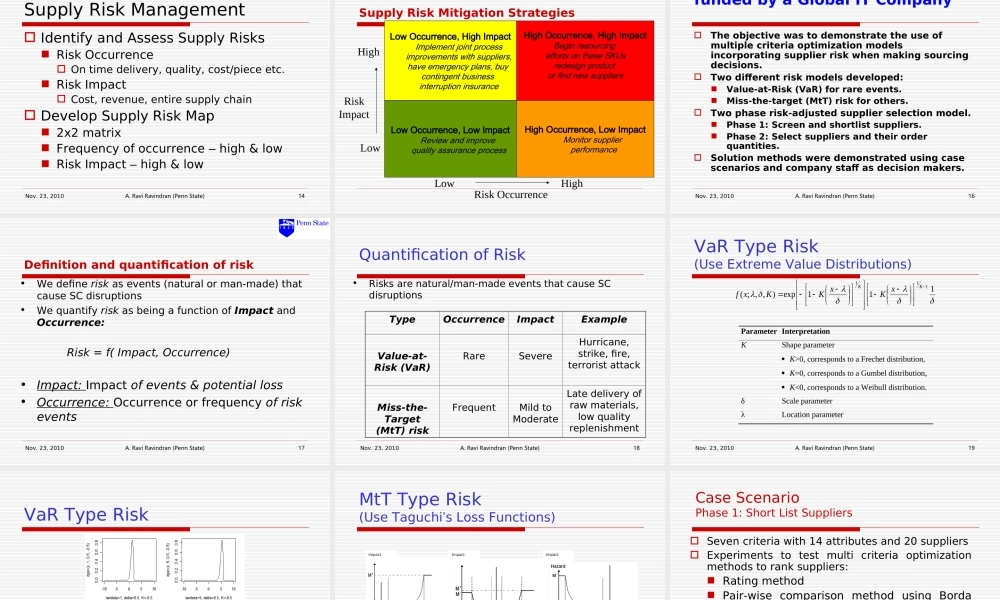

Global Sourcing and Vendor Risk Management in Supply ChainsProf. T. R. Natesan Endowment Lecture, ORSI, Chennai ChapterNovember 23, 2010Dr. A. Ravi RavindranProfessor of Industrial EngineeringREFERENCE Ravindran, A. Ravi, R. Ufuk Bilsel, Vijay Wadhwa and Tao Yang, “Risk Adjusted Multi Criteria Supplier Selection Models With Applications”, International Journal of Production Research, vol. 48, No. 2, PP. 405-424, January 2010.Nov. 23, 2010A. Ravi Ravindran (Penn State)2Nov. 23, 2010A. Ravi Ravindran (Penn State)3AgendaSupplier Selection problem and its ImportanceSupplier Risk ManagementCost of supply disruptionsRisk Identification and AssessmentRisk Mitigation StrategiesMulti Criteria Models for Supplier SelectionCase Study ResultsSupplier Selection Process In most procurement situations buyers have to choose among a set of suppliers. The buyer must choose which suppliers to order from and how much to order from each supplier.45Importance of Sourcing DecisionsWal-Mart assumed responsibility for global procurement from a third party in 2001 to better coordinate entire global supply chain from product development to delivery.Raw material cost is 40-60% of production cost for US manufacturers; for high tech companies, it can be up to 80%.Example : General MotorsCost of components and parts from outside suppliers exceed 50% of sales (2001 GM sales $180 billion)Life cycle of a new car18 months of concept phase, 18-24 months of Development phase, 7 years of program life to build cars for sales and 15 years of parts life for serviceMajor sourcing decisions with key suppliers are made 3 years before actual production!Nov. 23, 2010A. Ravi Ravindran (Penn State)6Vendor Management Cost Reduction Vers...