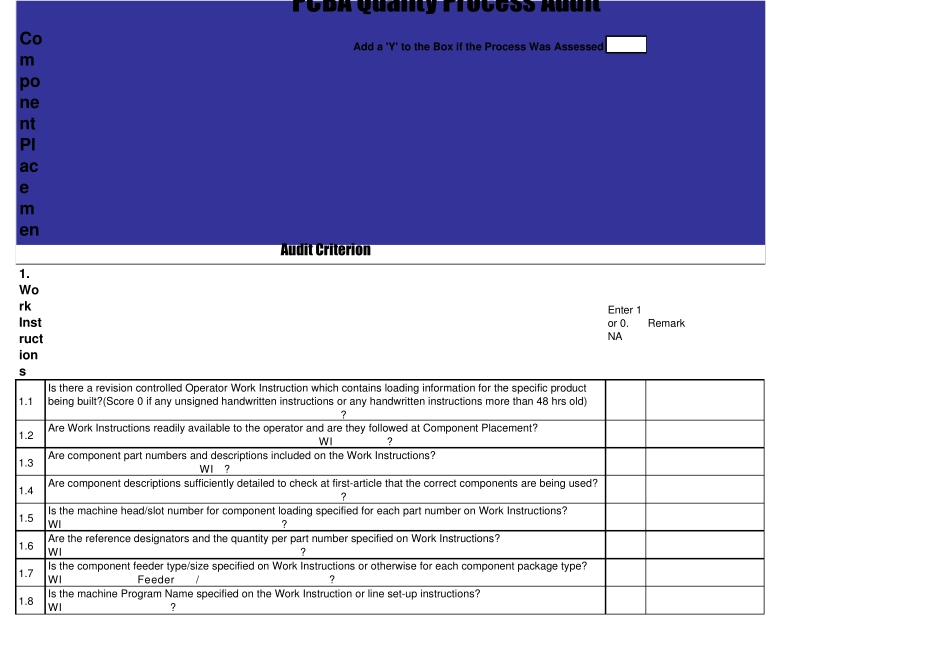

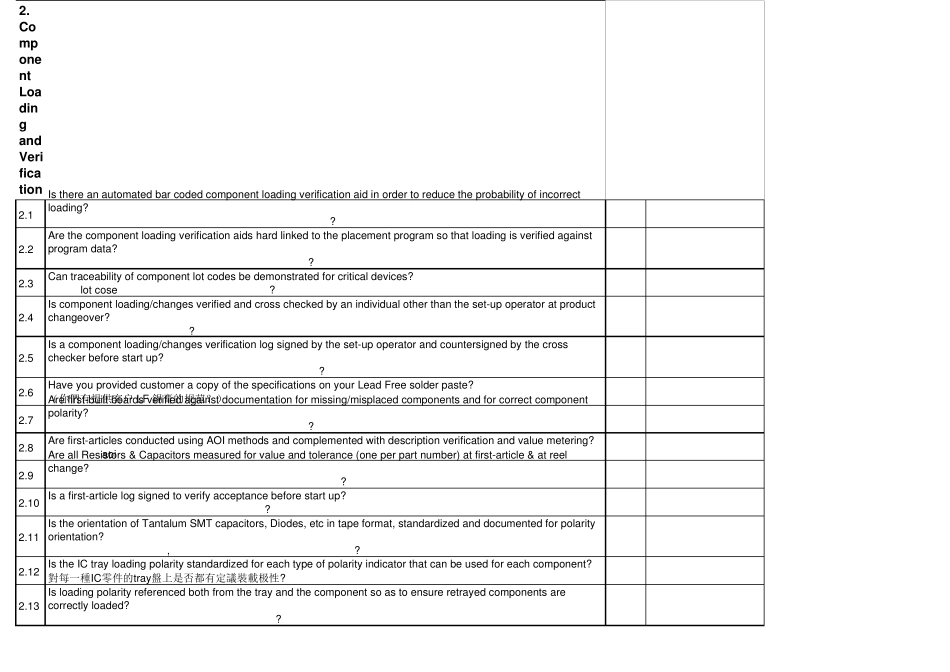

PCBA Quality Process AuditAdd a 'Y' to the Box if the Process Was AssessedComponentPlacemenAudit Criterion1.WorkInstructionsEnter 1or 0.NARemark1.1Is there a revision controlled Operator Work Instruction which contains loading information for the specific productbeing built?(Score 0 if any unsigned handwritten instructions or any handwritten instructions more than 48 hrs old)?1.2Are Work Instructions readily available to the operator and are they followed at Component Placement?WI?1.3Are component part numbers and descriptions included on the Work Instructions?WI?1.4Are component descriptions sufficiently detailed to check at first-article that the correct components are being used??1.5Is the machine head/slot number for component loading specified for each part number on Work Instructions?WI ?1.6Are the reference designators and the quantity per part number specified on Work Instructions?WI?1.7Is the component feeder type/size specified on Work Instructions or otherwise for each component package type?WIFeeder /?1.8Is the machine Program Name specified on the Work Instruction or line set-up instructions?WI?2.ComponentLoadingandVerification2.1Is there an automated bar coded component loading verification aid in order to reduce the probability of incorrectloading??2.2Are the component loading verification aids hard linked to the placement program so that loading is verified againstprogram data??2.3Can traceability of component lot codes be demonstrated for critical devices?lot cose?2.4Is component loading/changes verified and cross checked by an individual other than the set-up operator at productchangeover??2.5Is a component loading/changes verification log signed by the set-up operator and countersigned by the crosschecker before start up??2....