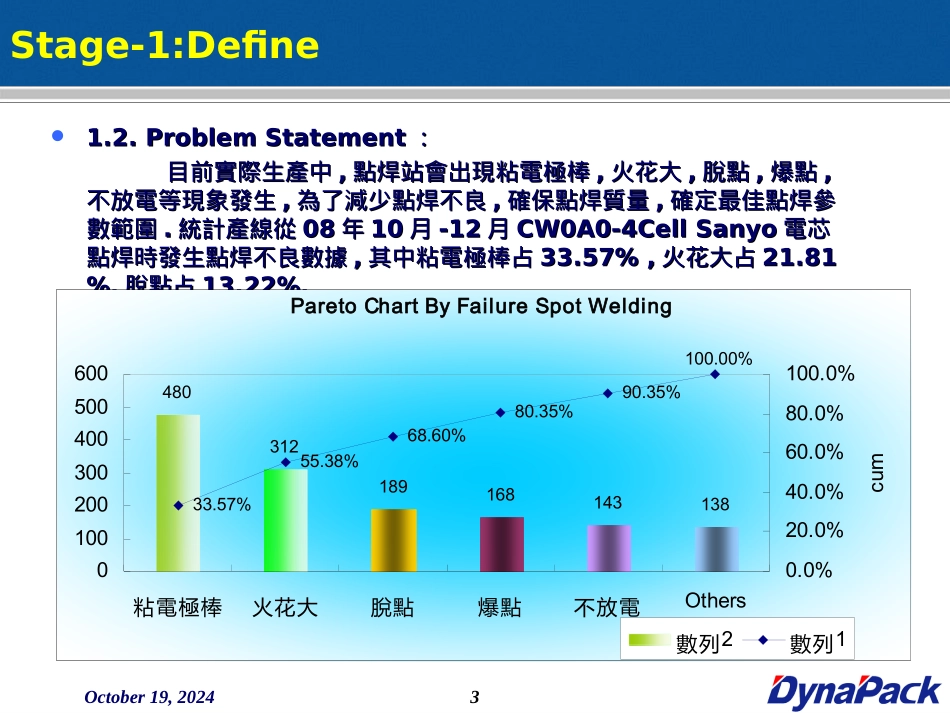

全因子試驗設計及MiniTab操作October19,20242Content1.Stage-1:Define1.Stage-1:Define–DOEcharter–ProblemStatement–VOC/KPOV/KPIV22.Stage-2:Measure:.Stage-2:Measure:–MSAPlan–Datacollection–MSAEvaluation3.Stage-3:Analyze3.Stage-3:Analyze–Cause&effectDiagram–PFMEA–FactorScreening4.Stage-4:Improve:4.Stage-4:Improve:–DOEdesign–DOEExecutionandAnalysis–ModelSimplificationandAnalysis–MathModuleBuilding–ParameterOptimization5.Stage-5:Control5.Stage-5:Control–PilotRun–NormalTest–CPK–StandardizationOctober19,20243Stage-1:Define1.2.ProblemStatement1.2.ProblemStatement::目前實際生產中目前實際生產中,,點焊站會出現粘電極棒點焊站會出現粘電極棒,,火花大火花大,,脫點脫點,,爆點爆點,,不放電等現象發生不放電等現象發生,,為了減少點焊不良為了減少點焊不良,,確保點焊質量確保點焊質量,,確定最佳點焊參確定最佳點焊參數範圍數範圍..統計產線從統計產線從0808年年1010月月-12-12月月CW0A0-4CellSanyoCW0A0-4CellSanyo電芯電芯點焊時發生點焊不良數據點焊時發生點焊不良數據,,其中粘電極棒占其中粘電極棒占33.57%,33.57%,火花大占火花大占21.8121.81%,%,脫點占脫點占13.22%.13.22%.ParetoChartByFailureSpotWelding48031218916814313833.57%55.38%68.60%80.35%90.35%100.00%0100200300400500600粘電極棒火花大脫點爆點不放電Others0.0%20.0%40.0%60.0%80.0%100.0%cum數列2數列1October19,20244TypeVOCKeyCustomerIssueCTQ點焊參數設置不當DOE點焊參數未做優化/點焊機台治具調整不當/點焊機台治具未做校驗人員作業不當SOP人員未參加教育訓練或未按照作業/脫點粘電極棒//火花大爆點沾銅OEMCustomerMUOQCKPOVSpotweldingProcessfailKPIVProcessParameterMaterialQualityControlPressureWeldingVoltageWeldingTimeFactor&levelDOE1.3.VOC&KPOV/KPIV1.3.VOC&KPOV/KPIVStage-1:DefineOctober19,20245Stage-2:Measure2.1.MSAPlan:2.1.MSAPlan:–目的:對拉力測試機執行量測系統分析,以確認測試儀器的准確性,以及確定不同人員對測試無影響–人員:郝尚書/劉澤文/常鵬–時間:2009/03/10~16–材料:拉力計(20kg)一台Al-P點焊樣品(共3種規格*30)Total90pcs–內容:3個測試人員每個人每種點焊樣本取10PCS,進行拉力測試並記錄數據.2.2PullingTestMachine2.2PullingTestMachine–設備編號:54W0600144–保養日期:2009/02/29–校驗日期:2009/06/06–效驗編號:830179October19,20246Stage-2:Measure2.3PullingTestmethod:2.3PullingTestmethod:2.4TestFlowChart:2.4TestFlowChart:樣本制作樣本編號及列檔人員測試數據記錄及分析合格判定設備調校執行檢定NGOK標准試打Al-P相同點焊參數穩定運行機台TopViewSideViewNi-tabCupperPullOctober19,20247Stage-2:Measure2.5TestData:2.5TestData:2.6NormalTest2.6NormalTestSamplelot郝尚書劉澤文常鵬Samplelot郝尚書劉澤文常鵬Samplelot郝尚書劉澤文常鵬12.73.2323.73.83.834.64.54.413.13322.33.83.234.44.54.612.732.823.43.83.534.24.64.612.72.7323.83.83.834.64.54.713.132.723.83.8334.54.64.61332.823.83.43.734.64.64.5132.83.123.53.83.634.64.64.61332.823.83.53.834.64.44.6133323.83.43.834.64.64.51333.123.63.6334.64.54.6ALplate1ALplate2ALplate365432199.99995908070605040302010510.1C1PercentMean3.69StDev0.6975N90AD3.836P-Value<0.005ProbabilityPlotofC1NormalOctober19,20248Stage-2:Measure2.5GageR&RChart:2.5GageR&RChart:Part-to-PartReprodRepeatGageR&R100500Percent%Contribution%StudyVar0.40.20.0SampleStDev_S=0.1712UCL=0.2939LCL=0.0486郝尚書常鵬劉澤文4.23.63.0SampleMean__X=3.707UCL=3.874LCL=3.540郝尚書常鵬劉澤文InspectorSamplelot劉澤文常鵬郝尚書321321321432劉澤文常鵬郝尚書432InspectorGagename:PullingforcemachineDateofstudy:2009/04/15Reportedby:ED/MUTolerance:0.1Misc:ComponentsofVariationSChartbyInspe...