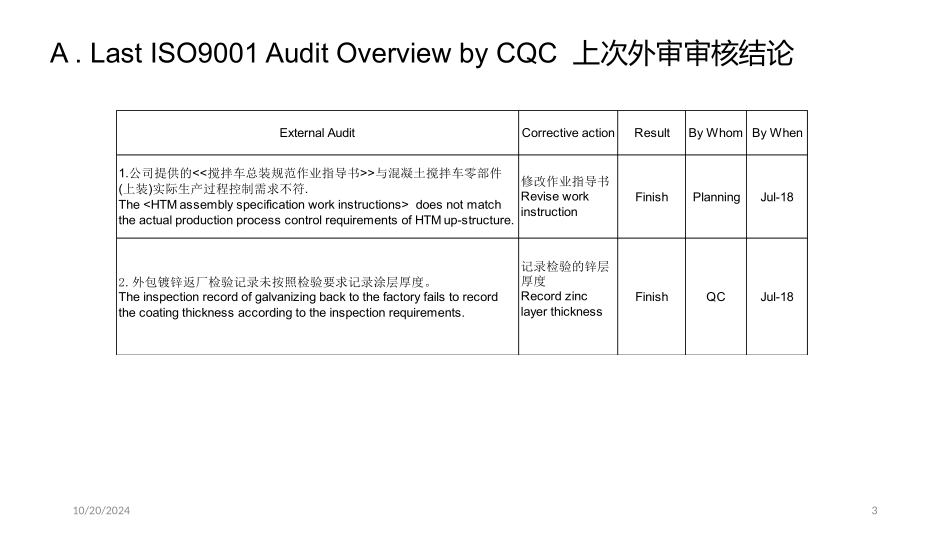

质量体系管理评审QMSManagementReview210/20/2024A.LastISO9001AuditOverviewbyCQC上次外审审核结论B.InternalAuditFindings(QMS)内审审核发现C.CustomerFeedback(Complaints/CustomerSurveys)顾客反馈D.SupplierPerformance供货商业绩E.ImprovementActions改进措施F.Costofpoorquality(COPQ)质量损失成本G.QualityTargetsAssessment质量目标评估H.ImprovementSuggestionsin2019(Product/QMS/Resources)2019改进建议(产品、体系、资源)I.2019QualityTargets(Draft)2019年质量目标(草案)310/20/2024A.LastISO9001AuditOverviewbyCQC上次外审审核结论ExternalAuditCorrectiveactionResultByWhomByWhen1.公司提供的<<搅拌车总装规范作业指导书>>与混凝土搅拌车零部件(上装)实际生产过程控制需求不符.ThedoesnotmatchtheactualproductionprocesscontrolrequirementsofHTMup-structure.修改作业指导书ReviseworkinstructionFinishPlanningJul-182.外包镀锌返厂检验记录未按照检验要求记录涂层厚度。Theinspectionrecordofgalvanizingbacktothefactoryfailstorecordthecoatingthicknessaccordingtotheinspectionrequirements.记录检验的锌层厚度RecordzinclayerthicknessFinishQCJul-18410/20/2024B.InternalAuditFindings(QMS)内部审核发现NoInternalAuditTypeDept.CorrectiveactionResultByWhomByWhen1标识和追溯性:半成品区4个料仓无任何标识。现场完成的搅拌车,滚筒上的钢印编号已看不清。Identificationandtraceability:4cementsiloinsemi-finishedproductsareahavenomark.ThemarkonthedrumoftheHTMonthesiteisnotclearfortraceability.Unqualified生产部Productioncontrol及时标注管理号,并保证清晰可辨认MarktheIDnumberintimeandensureitisclearfortraceability.FinishProduction2019/6/302客户财产保管:公司接受客户的底盘,存放在外库。询问仓管人员,不能提供清单明细。到外库查看,有2台底盘无任何标识。Customerpropertystorageconditions:Thecompanyreceivedcustomers'chassis.Askwarehousemanagementwhocouldnotprovidelistdetails.Checkoutsidethewarehouse,thereare2chassiswithoutanymark.Unqualified仓库Warehouse对底盘进行标识MarkthechassisFinishwarehouse2019/6/303质量目标:年度质量目标没达到的部门,需要制定相应的改进措施Qualityobjectives:Therearenoimprovementmeasuresforthedepartmentswhosequalityobjectivesarenotmet.ImprovementSuggestion采购部/销售部Purchasing/Sales制定相应的改进措施PrepareimprovementmeasuresInprocessSales/Pur.2019/6/304文件控制:计划部下发到生产车间的《焊接作业指导书》等新工艺文件没有受控章。Documentcontrol:The“weldingworkinstruction”issuedbyplanningdepartmentareunstamped.ImprovementSuggestion计划部ProductionPlan补盖受控章CoverthecontrolledstampedInprocessPlanning2019/6/305保管:外库有部分结构件无标识Storageconditions:SomestructuralpartsintheouterwarehousehavenoidentificationNo.ImprovementSuggestion仓库Warehouse对结构件进行标识MarkthestructuralpartsInprocesswarehouse2019/6/306产品的控制:生产现场缺少当天的设备点检及质量控制记录。Controlofproducts:Lackofequipmentinspectionandqualitycontrolrecordsontheproductionsite.ImprovementSuggestion生产部Productioncontrol增加记录AdditionrecordInprocessProduction2019/6/30510/20/2024C.CustomerFeedback(ComplaintsexceptingWarranty)顾客抱怨ProductType产品投诉数量ClaimQtyHTM55LMTParts11RP3BP170LRS622shaftcrackedmotorshaking;drumcrack27,RPLcrack9,coatproblem,impactpacking,paint,dimensionMixernoise2018CustomerComplaint顾客抱怨ClaimReason原因610/20/2024C.CustomerFeedback(ComplaintsexceptingWarranty)顾客抱怨710/20/20242018CustomerSatisfactionSurvey调查时间:2018年3月—2018年12月Timeduration:March201...