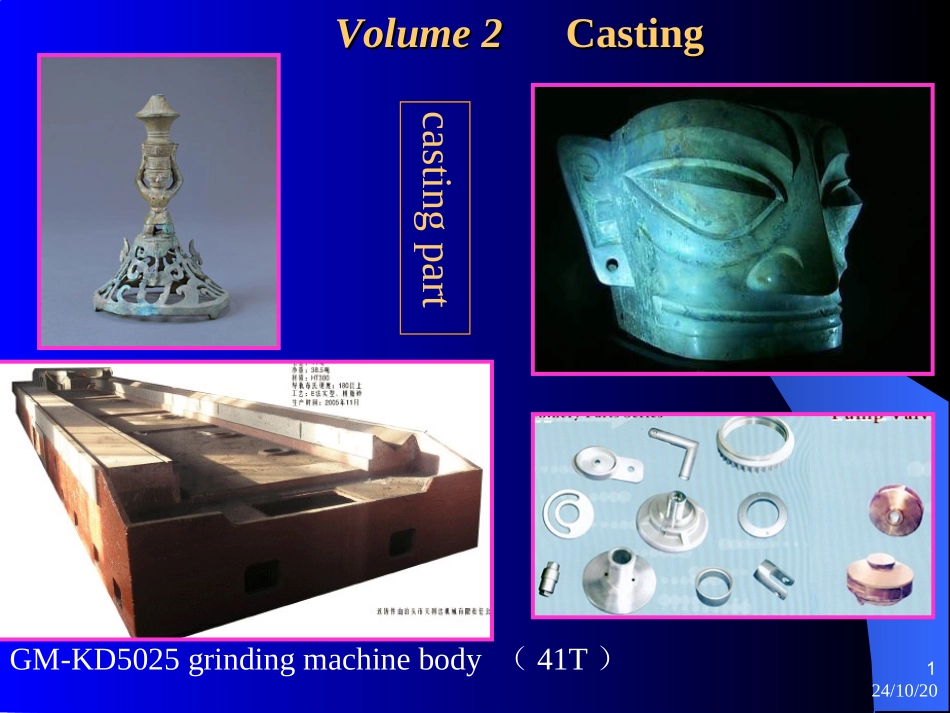

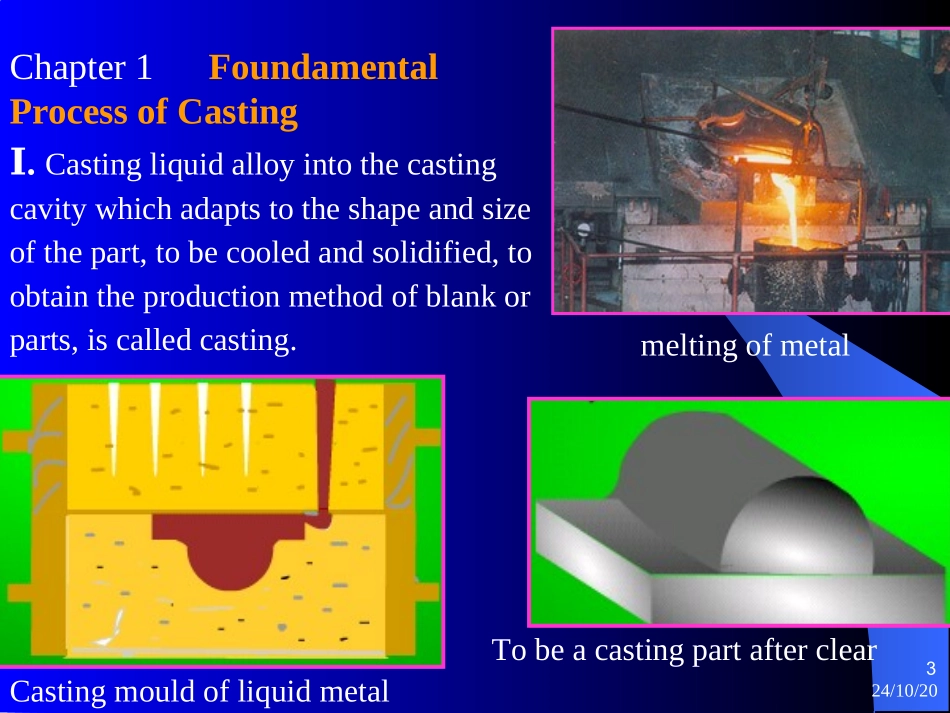

24/10/201GM-KD5025grindingmachinebody(41T)castingpartVolume2Volume2CastingCasting1.Casting1.CastingCastingliquidalloyintothecastingcavitywhichadaptstotheshapeandsizeofthepart,tobecooledandsolidified,toobtaintheproductionmethodofblankorparts,iscalledcasting24/10/20224/10/203meltingofmetalCastingmouldofliquidmetalTobeacastingpartafterclearChapter1FoundamentalProcessofCastingⅠ.Castingliquidalloyintothecastingcavitywhichadaptstotheshapeandsizeofthepart,tobecooledandsolidified,toobtaintheproductionmethodofblankorparts,iscalledcasting.24/10/204Ⅱ.CharacteristicsofCasting1.Canbemadetocomplicatedform,especiallyfortheworkblankwithcomplicatedlumen;2.Thecastingweightandthealloycanbeusedareunrestricted;3.Hassmallallowanceofmachingandlowcost。Therefore,thecastingprocessiswidelyapplicated.But,(1)tensilestrengthandimpacttoughnessarenotasgoodasforgingandwelding.(2)complicatedprocess,higherrejectrate.24/10/205ⅠⅠ.concept.concept::processofliquidalloyprocessofliquidalloyfillinginthecastingmold—Moldfillinginthecastingmold—MoldFilling.CapbilityofliquidalloyFilling.Capbilityofliquidalloyfullyfullyfillinginthemoldfillinginthemold,,togetcompletetogetcompleteform,clearedgesharpness--Liquidform,clearedgesharpness--LiquidAlloyAlloyFillingFillingAbility.Ability.spiralspecimenSection1Section1MoldFillingofLiquidAlloyMoldFillingofLiquidAlloyⅡ.LiquidAlloyfillingcapacityinfluencefactors:1.Mobilityofalloy(commonlymeasuredbyspiralspecimen):Mobility,FillingCapacity,moreeasiertogetedgesharpness-thin-complicatedcastingpart.24/10/2061)MeasurementofAlloyMobility:byspiralspecimen.Underthesamepouringcondition,thelongerspiralspecimen,thebetterMobility。2)Influenceoffactors:mainlychemicalingredient.Thedistanceofliquidusandsolidus(Tl-Ts)iscalledMetacollid.2.Pouringcondition(Pouringtemperature,moldfillingpressure):temperature,pressure--Moldfillingcapability.3.castingmouldfillingcondition(moldheatstoragecapacity,moldtemperatureandthegasesinmold):heatstoragecapacity,moldtemperature,gasesexaustingcondition--MoldFillingCapability。Lowmoldfillingcapabilitycanresultsindefects:ColdShut、Shortrun(misrun).Fe-Calloymobility--carboncontentThebiggerMetacollidhas,theAlloymobilityisworse,andviceversa.Fig.24/10/207CastingsolidificationpatternSection2Section2CastingsolidificationandshrinkⅠ.Castingpartsolidificationsolidifylayerbylayer(充型能力好,便于补缩)1.凝固方式糊状凝固(易形成缩孔、难以获得结晶紧实的铸件)pastysolidfyingmiddlesolidfying中间凝固(介于上两者间)solidificationpattern(S-D)ingredientstemperatureS.L.SurfacecentreCastingpartLiquidussolidus24/10/208Rangeofalloycrystaltemperature2、S-DmaininfluencefactorsTEMPgradientalloypropertyheatstoragecapacitypouringTEMPⅡ.CastingAlloyShrink(Shrinkage)Ontheprocessofpouring、solidfying、coolingtilltoindoortemperature,thephenomenonthatthevolumeandsizereduce,iscalledshrink.1.Essenceofshrink:electronholereducingwithTEMP,atomicseparationshortened,thevolumeandsizereduced。liquidshrinkεl:Tp~Tl2.Clasificationsolidfyingshrinkεs:Tl~Tp,solidshrinkεs:Ts~IndoorTEMP。S-Dinfluencefactors24/10/209Ⅲ.shrinkagecavityandshrinkageporosityincastingpart1.Formingofshrinkagecavityandshrinkageporosity:Intheliquidalloycondensationprocess,iftheabbreviatedvolumecannotbecomplemented,thecavitiesandholeswillbegeneratedatthefinalsolidficationposit...