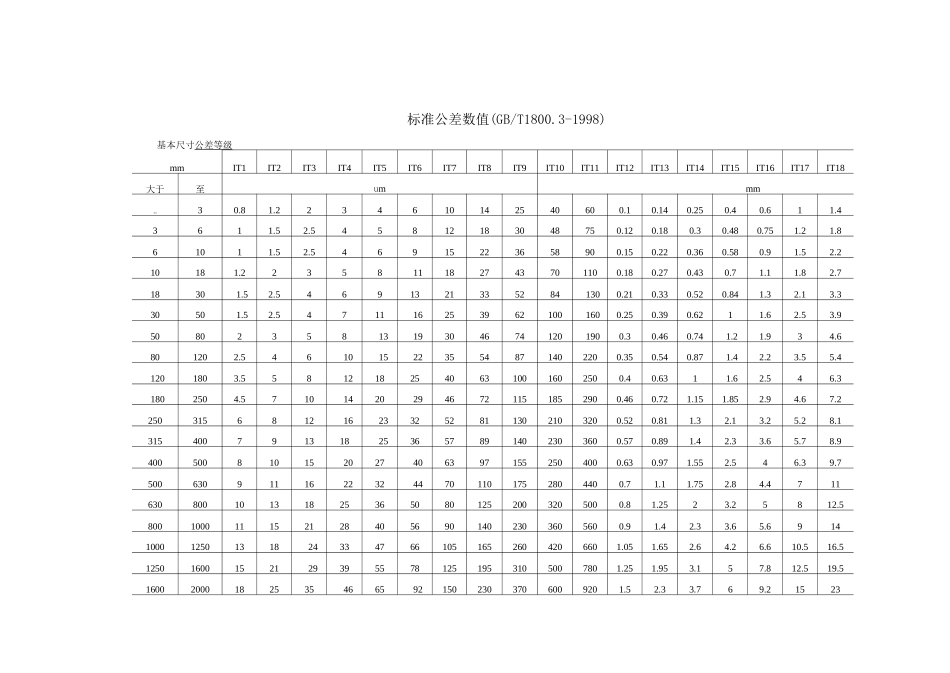

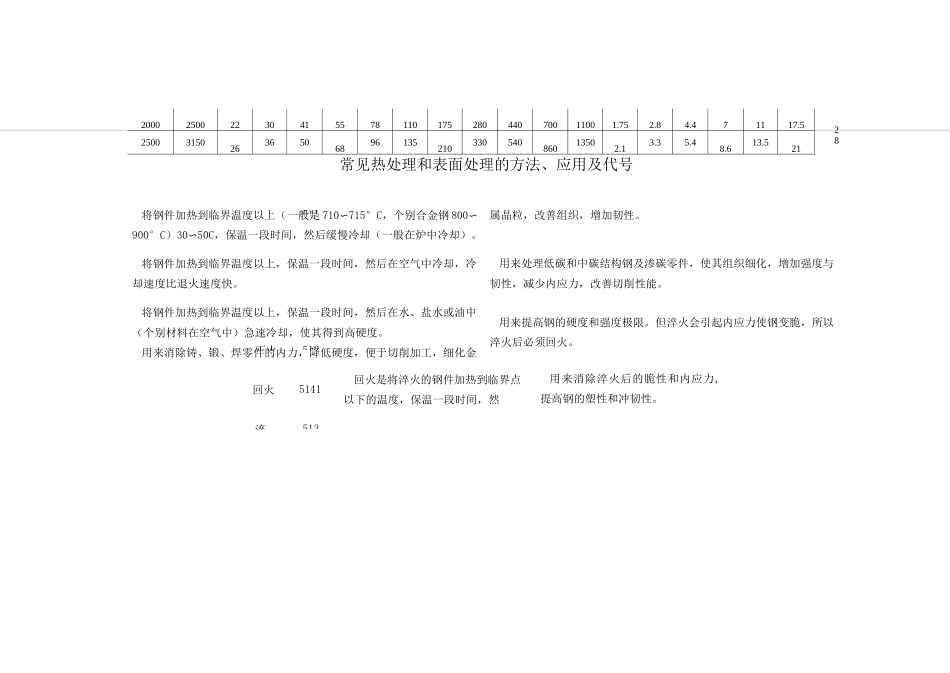

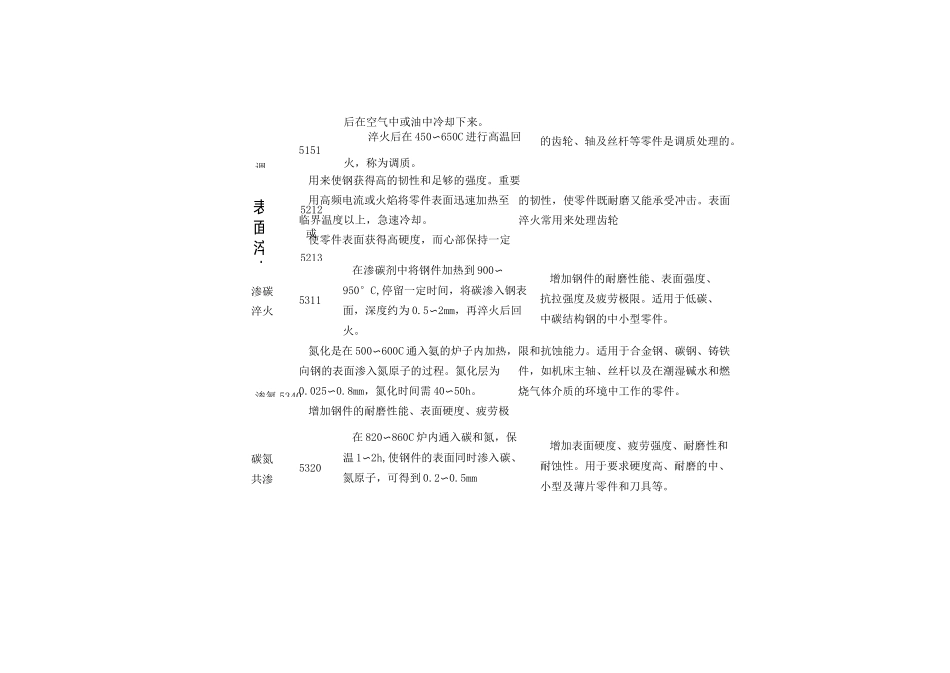

标准公差数值(GB/T1800.3-1998)基本尺寸公差等级mmIT1IT2IT3IT4IT5IT6IT7IT8IT9IT10IT11IT12IT13IT14IT15IT16IT17IT18大于至ummm--30.81.2234610142540600.10.140.250.40.611.43611.52.545812183048750.120.180.30.480.751.21.861011.52.546915223658900.150.220.360.580.91.52.210181.2235811182743701100.180.270.430.71.11.82.718301.52.546913213352841300.210.330.520.841.32.13.330501.52.54711162539621001600.250.390.6211.62.53.95080235813193046741201900.30.460.741.21.934.6801202.5461015223554871402200.350.540.871.42.23.55.41201803.55812182540631001602500.40.6311.62.546.31802504.571014202946721151852900.460.721.151.852.94.67.2250315681216233252811302103200.520.811.32.13.25.28.1315400791318253657891402303600.570.891.42.33.65.78.94005008101520274063971552504000.630.971.552.546.39.750063091116223244701101752804400.71.11.752.84.4711630800101318253650801252003205000.81.2523.25812.58001000111521284056901402303605600.91.42.33.65.6914100012501318243347661051652604206601.051.652.64.26.610.516.5125016001521293955781251953105007801.251.953.157.812.519.5160020001825354665921502303706009201.52.33.769.21523511正火28512淬51320002500223041557811017528044070011001.752.84.471117.525003150263650689613521033054086013502.13.35.48.613.521常见热处理和表面处理的方法、应用及代号将钢件加热到临界温度以上(一般是 710〜715°C,个别合金钢 800〜900°C)30〜50C,保温一段时间,然后缓慢冷却(一般在炉中冷却)。将钢件加热到临界温度以上,保温一段时间,然后在空气中冷却,冷却速度比退火速度快。将钢件加热到临界温度以上,保温一段时间,然后在水、盐水或油中(个别材料在空气中)急速冷却,使其得到高硬度。用来消除铸、锻、焊零件的内力,降低硬度,便于切削加工,细化金属晶粒,改善组织,增加韧性。用来处理低碳和中碳结构钢及渗碳零件,使其组织细化,增加强度与韧性,减少内应力,改善切削性能。用来提高钢的硬度和强度极限。但淬火会引起内应力使钢变脆,所以淬火后必须回火。回火5141回火是将淬火的钢件加热到临界点以下的温度,保温一段时间,然用来消除淬火后的脆性和内应力,提高钢的塑性和冲韧性。调表面淬火5212或5213渗氮 5340后在空气中或油中冷却下来。淬火后...