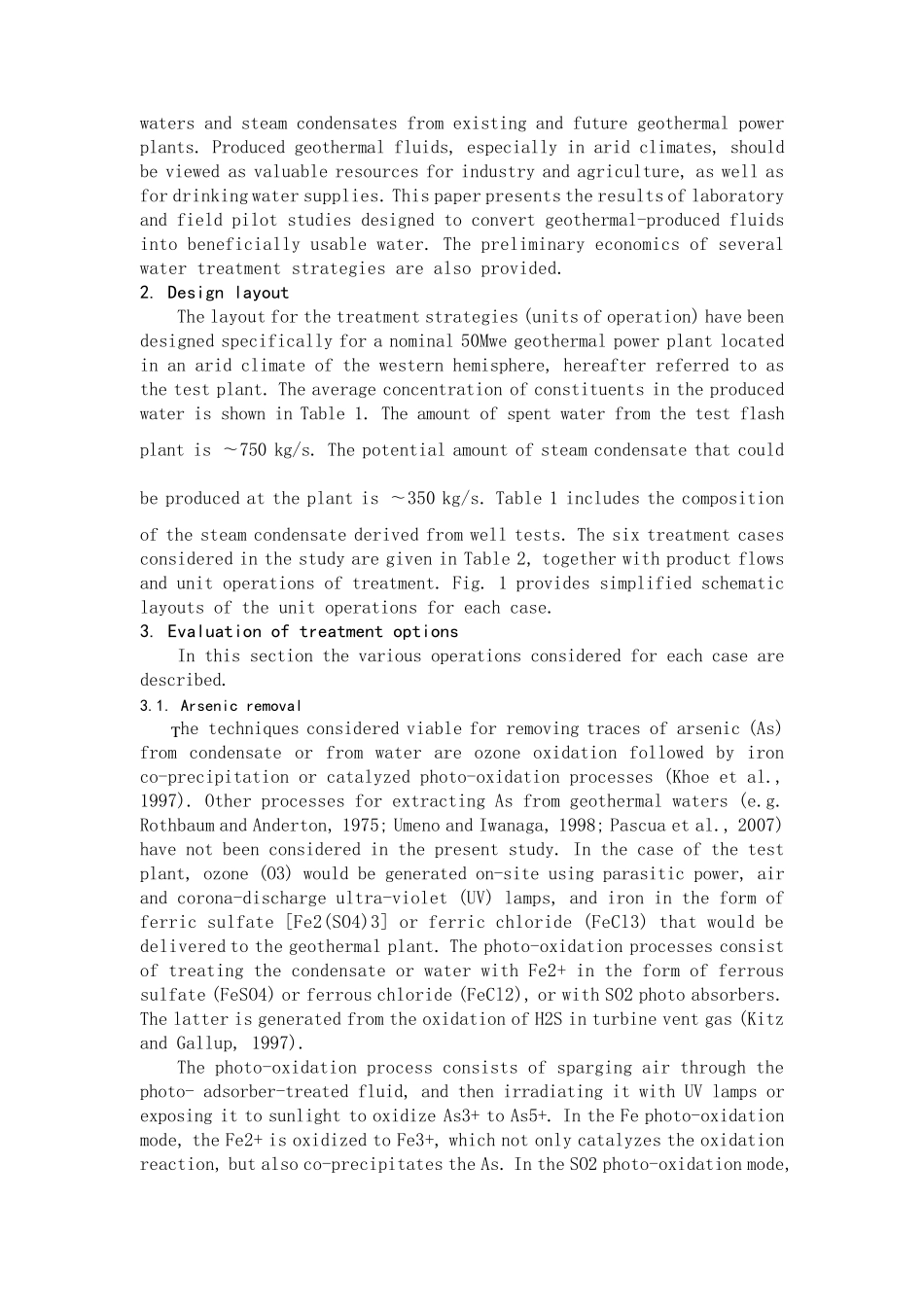

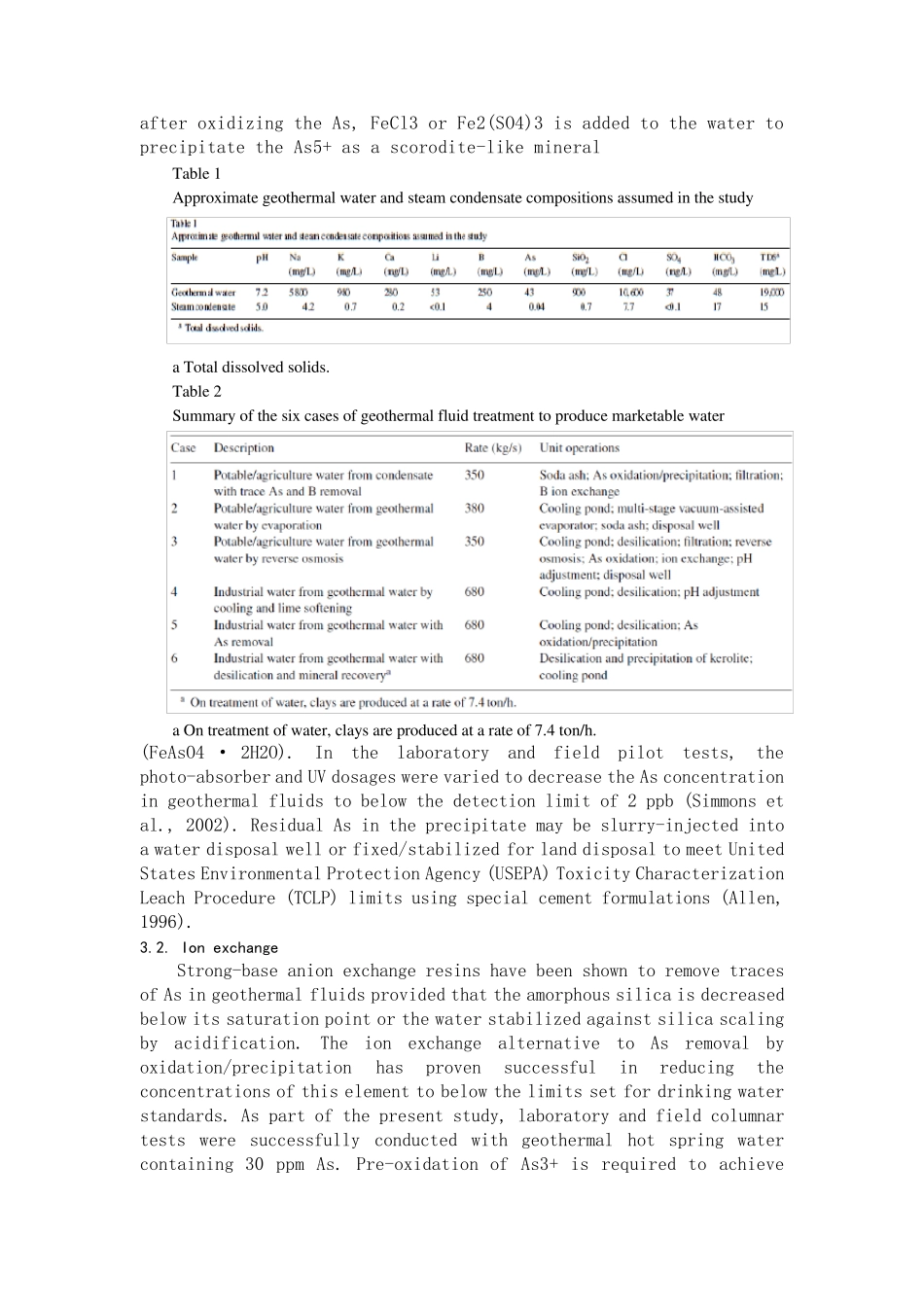

Treatment of geothermal waters for production of industrial, agricultural or drinking water Darrell L. Gallup ∗ Chevron Corporation, Energy Technology Company, 3901 Briarpark Dr., Houston, Texas 77042, USA Received 14 March 2007; accepted 16 July 2007 Available online 12 September 2007 Abstract A conceptual study has been carried out to convert geothermal water and condensate into a valuable industrial, agricultural or drinking water resource. Laboratory and field pilot test studies were used for the conceptual designs and preliminary cost estimates, referred to treatment facilities handling 750 kg/s of geothermal water and 350 kg/s of steam condensate. The experiments demonstrated that industrial, agricultural and drinking water standards could probably be met by adopting certain operating conditions. Six different treatments were examined. Unit processes for geothermal water/condensate treatment include desilication of the waters to produce marketable minerals, removal of dissolved solids by reverse osmosis or evaporation, removal of arsenic by oxidation/precipitation, and removal of boron by various methods including ion exchange. The total project cost estimates, with an accuracy of approximately ±25%, ranged from US$ 10 to 78 million in capital cost, with an operation and maintenance (or product) cost ranging from US$ 0.15 to 2.73m− 3 of treated water. © 2007 CNR. Published by Elsevier Ltd. All rights reserved. Keywords: Geothermal water treatment; Water resources; Desilication; Arsenic; Boron 1. Introduction With the world entering an age of water shortages and arid farming land, it is increasingly important that we find ways of recycling wastewater. The oil, gas and geothermal industries, for example, extr...