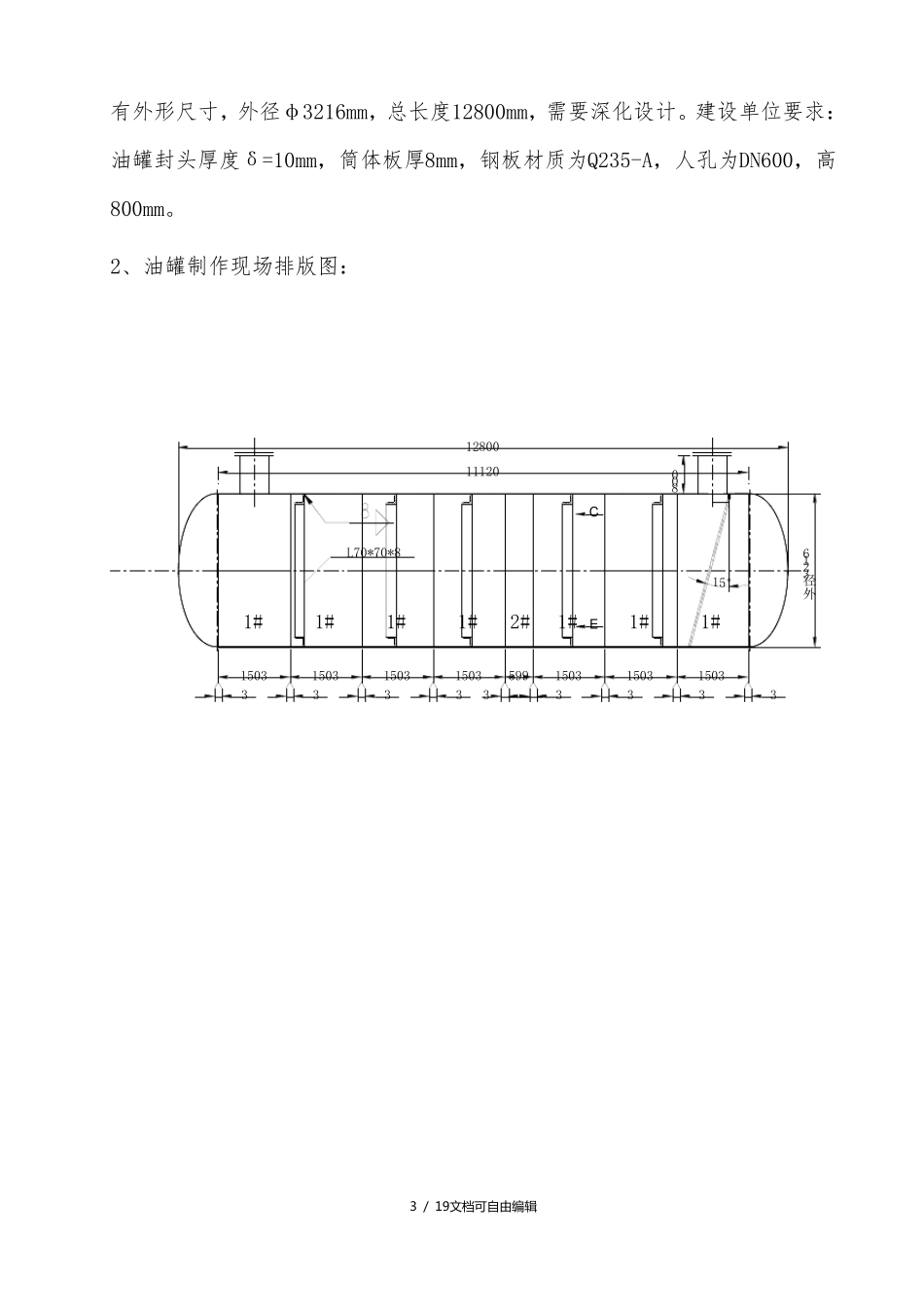

100m³常压卧式油罐一、单位工程概况························1、工程概况·························2、油罐制作现场排版图:二、施工方案··························制作方案1 / 19文档可自由编辑 2 2··················· 3 61.施工前准备 ························ 62.油罐制作 ························· 63.组对拼装 ························· 104.制造过程质量控制 ····················· 115.焊接检验 ························· 146.试验 ··························· 157.油罐的防腐 ························ 15三.验收···························· 16四、油罐吊装方案························ 171.油罐概况························· 172.施工准备 ························· 173.吊装 ··························· 18一、单位工程概况1、工程概况1.1、本工程为10×100m罐组,现场制作工程量为20台。原设计图纸油罐仅2 / 19文档可自由编辑有外形尺寸,外径φ3216mm,总长度12800mm,需要深化设计。建设单位要求:油罐封头厚度δ=10mm,筒体板厚8mm,钢板材质为Q235-A,人孔为DN600,高800mm。2、油罐制作现场排版图:12800C15°1#150331#150331#150331#1503332#5991#15033E1#150331#150333外径3216L70*70*8800111203 / 19文档可自由编辑V型坡口,角度32.5±2°钝边1.5mm3196EHA 3196×10-Q235A JB/T4746-2002以内径为基准的椭圆形封头数量:20个全部拼接焊接接头100%射线检测III级合格,(由甲方负责)出厂质量证明文件齐全40840IIφ20100IIφ20IR40450I3408φ22满焊R30R1200=3000810*3320945°60点焊30油罐内部斜梯图φ203179340R304 / 19文档可自由编辑C向、E向旋转860°±5°60°±5°110罐壁内侧罐壁焊缝祥图(纵缝对称错开)包边角钢对接焊缝详图角钢加强圈底部导油孔接管D6305°35±8D98082±0.5862R335±5°20°±2°8DN600人孔接管焊接补强图135R1831#7块100782#...