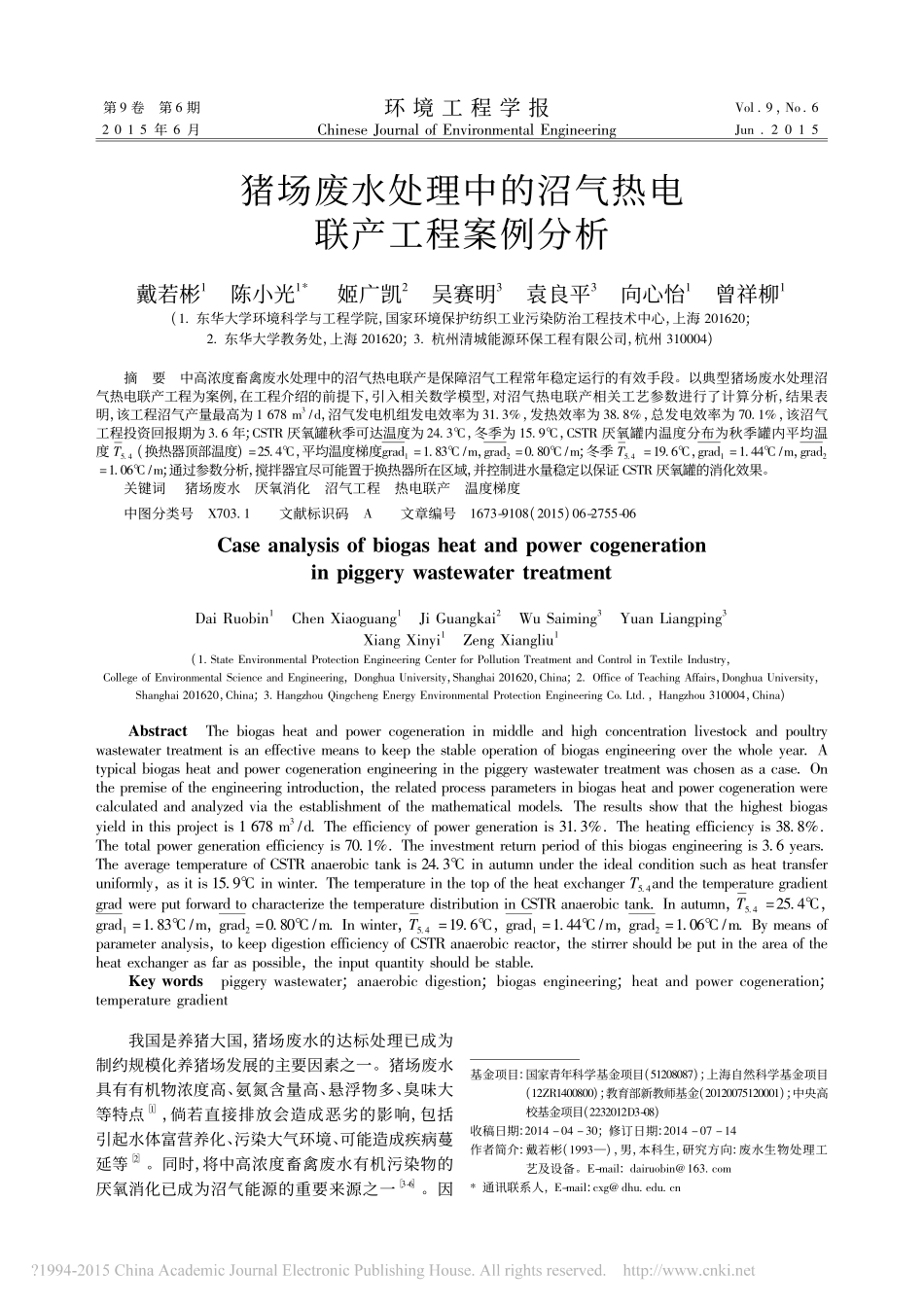

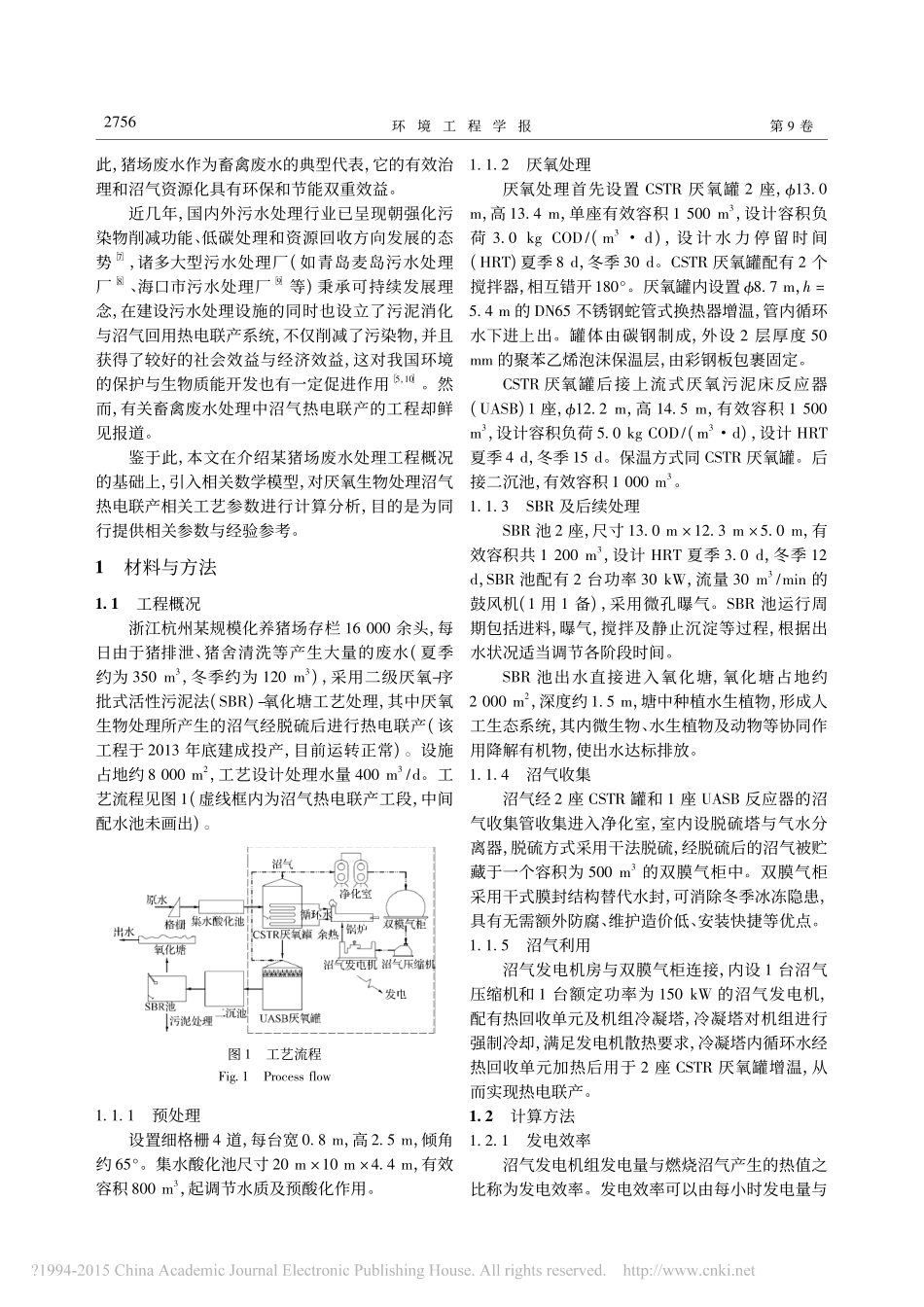

第9卷第6期环境工程学报Vol.9,No.62015年6月ChineseJournalofEnvironmentalEngineeringJun.2015猪场废水处理中的沼气热电联产工程案例分析戴若彬1陈小光1*姬广凯2吴赛明3袁良平3向心怡1曾祥柳1(1.东华大学环境科学与工程学院,国家环境保护纺织工业污染防治工程技术中心,上海201620;2.东华大学教务处,上海201620;3.杭州清城能源环保工程有限公司,杭州310004)摘要中高浓度畜禽废水处理中的沼气热电联产是保障沼气工程常年稳定运行的有效手段。以典型猪场废水处理沼气热电联产工程为案例,在工程介绍的前提下,引入相关数学模型,对沼气热电联产相关工艺参数进行了计算分析,结果表明,该工程沼气产量最高为1678m3/d,沼气发电机组发电效率为31.3%,发热效率为38.8%,总发电效率为70.1%,该沼气工程投资回报期为3.6年;CSTR厌氧罐秋季可达温度为24.3℃,冬季为15.9℃,CSTR厌氧罐内温度分布为秋季罐内平均温度T5.4(换热器顶部温度)=25.4℃,平均温度梯度grad1=1.83℃/m,grad2=0.80℃/m;冬季T5.4=19.6℃,grad1=1.44℃/m,grad2=1.06℃/m;通过参数分析,搅拌器宜尽可能置于换热器所在区域,并控制进水量稳定以保证CSTR厌氧罐的消化效果。关键词猪场废水厌氧消化沼气工程热电联产温度梯度中图分类号X703.1文献标识码A文章编号1673-9108(2015)06-2755-06CaseanalysisofbiogasheatandpowercogenerationinpiggerywastewatertreatmentDaiRuobin1ChenXiaoguang1JiGuangkai2WuSaiming3YuanLiangping3XiangXinyi1ZengXiangliu1(1.StateEnvironmentalProtectionEngineeringCenterforPollutionTreatmentandControlinTextileIndustry,CollegeofEnvironmentalScienceandEngineering,DonghuaUniversity,Shanghai201620,China;2.OfficeofTeachingAffairs,DonghuaUniversity,Shanghai201620,China;3.HangzhouQingchengEnergyEnvironmentalProtectionEngineeringCo.Ltd.,Hangzhou310004,China)AbstractThebiogasheatandpowercogenerationinmiddleandhighconcentrationlivestockandpoultrywastewatertreatmentisaneffectivemeanstokeepthestableoperationofbiogasengineeringoverthewholeyear.Atypicalbiogasheatandpowercogenerationengineeringinthepiggerywastewatertreatmentwaschosenasacase.Onthepremiseoftheengineeringintroduction,therelatedprocessparametersinbiogasheatandpowercogenerationwerecalculatedandanalyzedviatheestablishmentofthemathematicalmodels.Theresultsshowthatthehighestbiogasyieldinthisprojectis1678m3/d.Theefficiencyofpowergenerationis31.3%.Theheatingefficiencyis38.8%.Thetotalpowergenerationefficiencyis70.1%.Theinvestmentreturnperiodofthisbiogasengineeringis3.6years.TheaveragetemperatureofCSTRanaerobictankis24.3℃inautumnundertheidealconditionsuchasheattransferuniformly,asitis15.9℃inwinter.ThetemperatureinthetopoftheheatexchangerT5.4andthetemperaturegradientgradwereputforwardtocharacterizethetemperaturedistributioninCSTRanaerobictank.Inautumn,T5.4=25.4℃,grad1=1.83℃/m,grad2=0.80℃/m.Inwinter,T5.4=19.6℃,grad1=1.44℃/m,grad2=1.06℃/m.Bymeansofparameteranalysis,tokeepdigestionefficiencyofCSTRanaerobicreactor,thestirrershouldbeputintheareaoftheheatexchangerasfaraspossible,theinputquantityshouldbestable.Keywordspiggerywastewater;anaerobicdigestion;biogasengineering;heatandpowercogeneration;temperaturegradient基金项目:国家青年科学基金项目(51208087);上海自然科学基金项目(12ZR1400800);教育部新教师基金(20120075120001);中央高校基金项目(2232012D3-08)收稿日期:2014-04-30;修订日期:2014-07-14作者简介:戴若彬(1993—),男,本科生,研究方向:废水生物处理工艺及设备。E-mail:dairuobin@163.com*通讯联系人,E-mail:cxg@dhu.edu.cn我国是养猪大国,猪场废水的达标处理已成为制约规模化养猪场发展的主要因素之一。猪场废水具有有机物浓度...