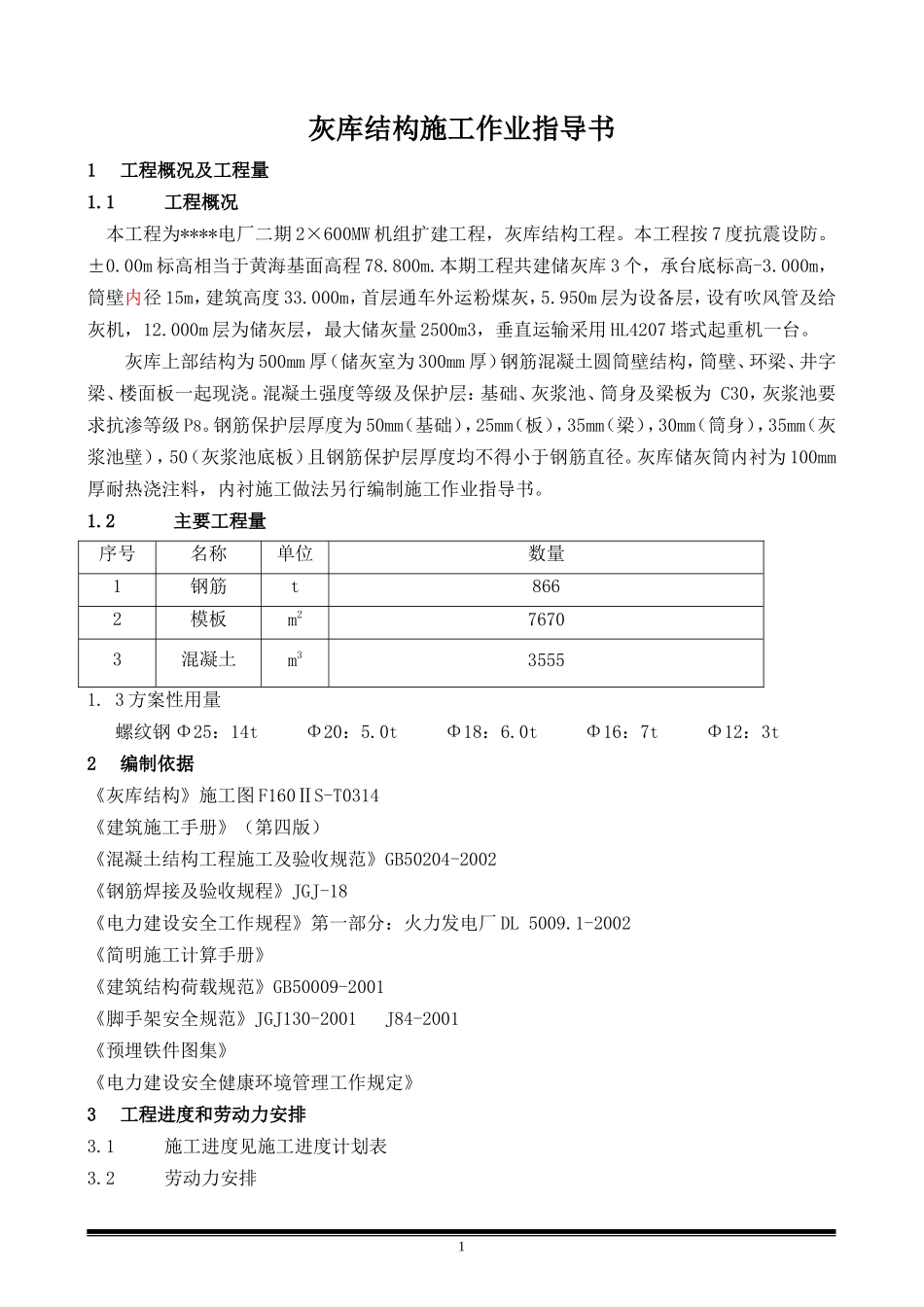

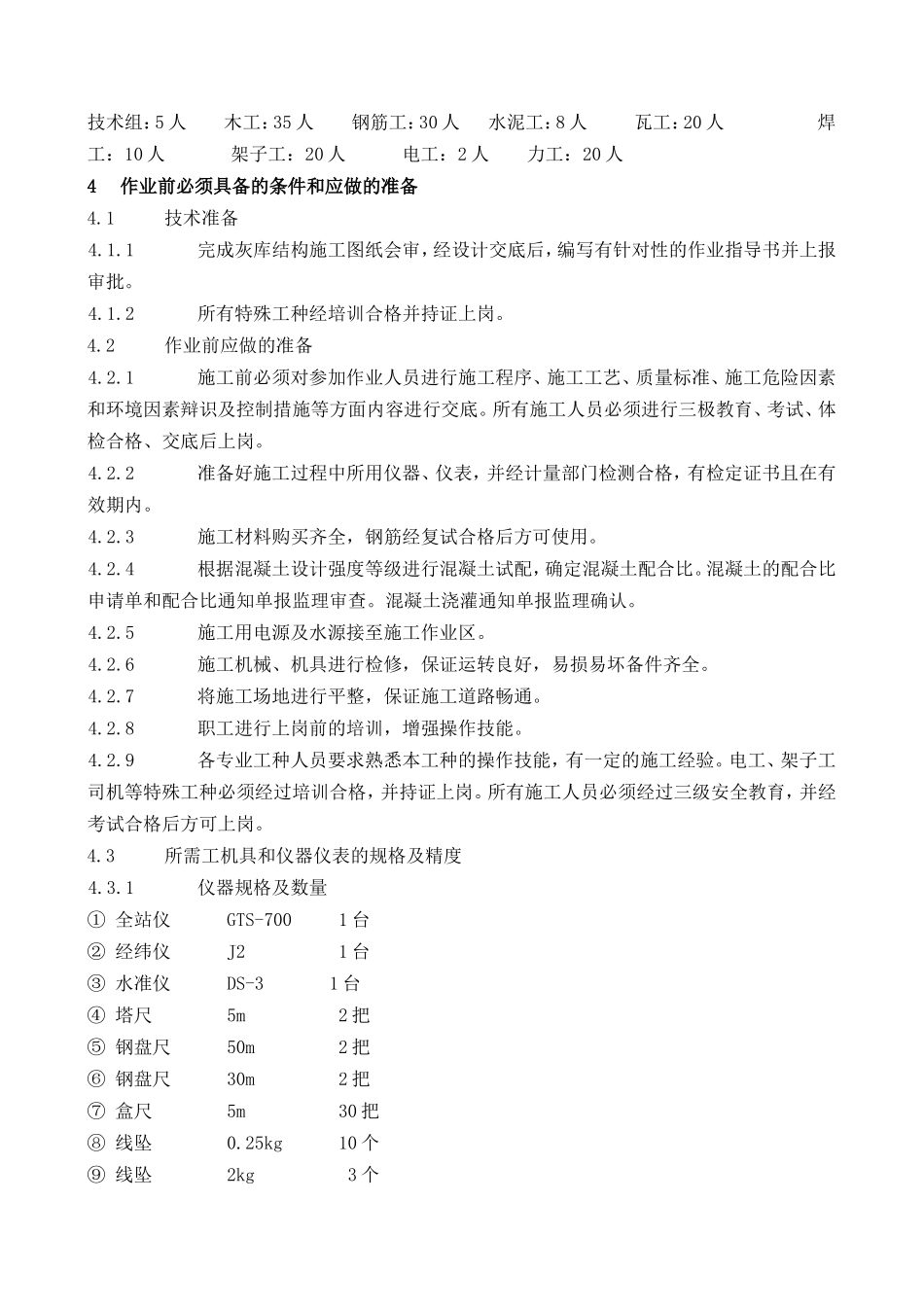

目录1工程概况及工程量........................................................................................12编制依据........................................................................................................13工程进度和劳动力安排................................................................................24作业前必须具备的条件和应做的准备........................................................25作业的程序步骤和方法................................................................................35.1施工顺序.......................................................................................................35.2作业步骤.......................................................................................................45.2.3钢筋工程....................................................................................................65.2.4模板工程..................................................................................................115.2.5埋件的制作和安装..................................................................................155.2.6混凝土工程..............................................................................................165.2.7成品保护..................................................................................................186作业质量要求和质量通病及预防..............................................................186.1质量目标.....................................................................................................186.2工程质量验评标准.....................................................................................186.3关键检查项目、隐蔽工程及停工待检点的确定.....................................196.4作业质量要点、质量保证措施.................................................................196.5质量标准.....................................................................................................196.6质量通病及预防.........................................................................................207作业安全技术措施......................................................................................218作业的环境管理..........................................................................................239附录..............................................................................................................24灰库结构施工作业指导书1工程概况及工程量1.1工程概况本工程为****电厂二期2×600MW机组扩建工程,灰库结构工程。本工程按7度抗震设防。±0.00m标高相当于黄海基面高程78.800m.本期工程共建储灰库3个,承台底标高-3.000m,筒壁内径15m,建筑高度33.000m,首层通车外运粉煤灰,5.950m层为设备层,设有吹风管及给灰机,12.000m层为储灰层,最大储灰量2500m3,垂直运输采用HL4207塔式起重机一台。灰库上部结构为500mm厚(储灰室为300mm厚)钢筋混凝土圆筒壁结构,筒壁、环梁、井字梁、楼面板一起现浇。混凝土强度等级及保护层:基础、灰浆池、筒身及梁板为C30,灰浆池要求抗渗等级P8。钢筋保护层厚度为50mm(基础),25mm(板),35mm(梁),30mm(筒身),35mm(灰浆池壁),50(灰浆池底板)且钢筋保护层厚度均不得小于钢筋直径。灰库储灰筒内衬为100mm厚耐热浇注料,内衬施工做法另行编制施工作业指导书。1.2主要工程量序号名称单位数量1钢筋t8662模板m276703混凝土m335551.3方案性用量螺纹钢Φ25:14tΦ20:5.0tΦ18:6.0tΦ16:7tΦ12:3t2编制依据《灰库结构》施工图F160ⅡS-T0314《建筑施工手册》(第四版)《混凝土结构工程施工及验收规范》GB50204-200...