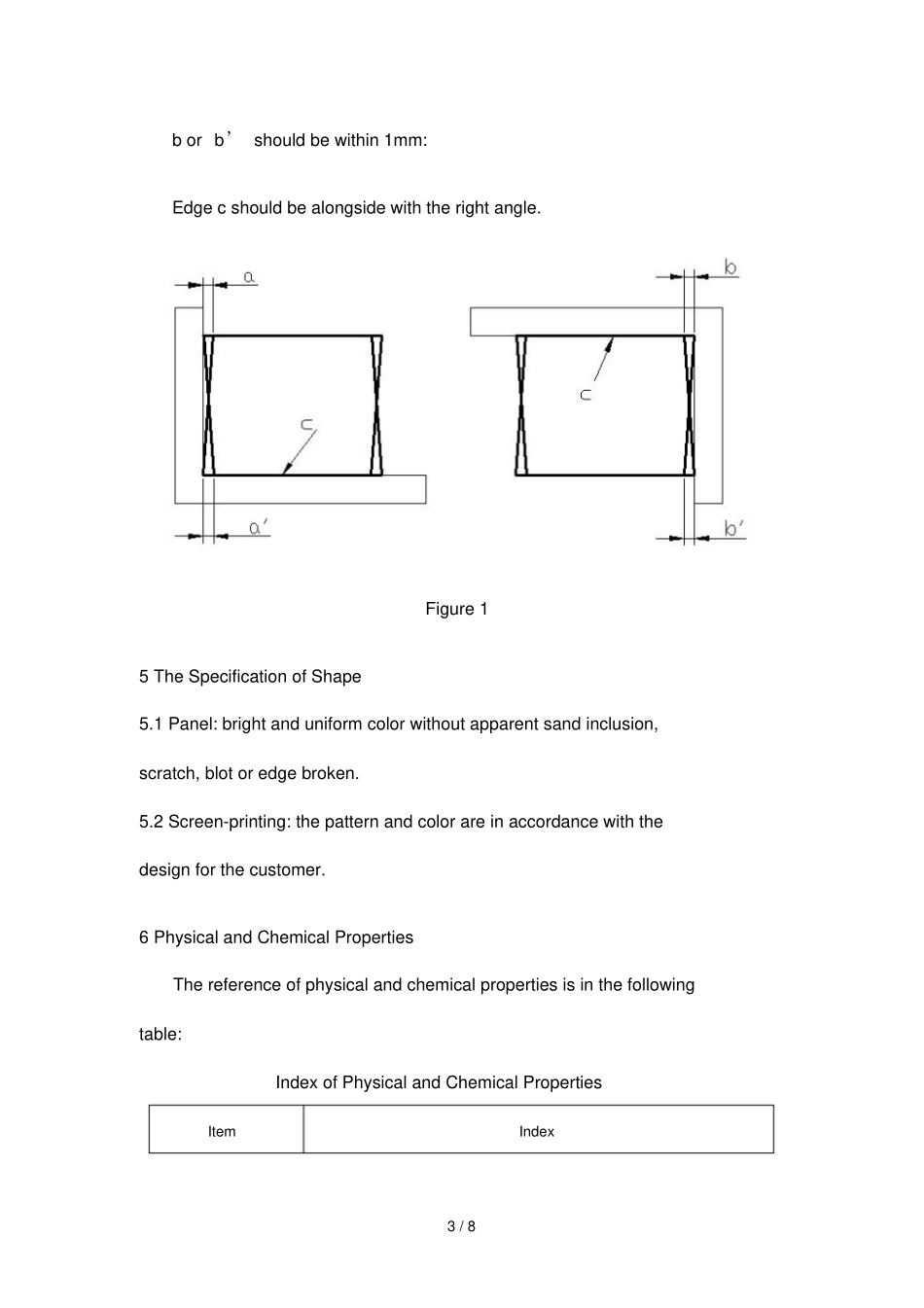

1/8ProductdescriptionProductName:BlackTransparentElectromagneticOvenpanelGuangdongKediGlass-ceramicIndustrialCo.,Ltd.1ScopeofApplicationThismanualappliestoblacktransparentglassceramicspanel.2ReferenceStandardGuangdongProvinceIndustryStandard,Q/PKT02-2007BroadBlackTransparentGlass-ceramicPlate.3MaterialBlacktransparentglassceramicsareusedtomeetthespecialrequirementsofelectromagneticovenStandardfeatureswhicharetobedescribedrespectively,fittheRoHSrules.3.1Characteristicsofglassceramics3.1.1MaximumServiceTemperature:Theoriginalcoloroftheplatewillchangeatthetemperatureof780℃.3.1.2TemperatureofThermalShock2/8780℃(thermalshockresistancetest:afterheatingtheelectricfurnaceandkeepingthetemperatureat780℃,placetheplateinitfor30minutes,thecharacteristicsoftheplatekeepsstablewhenitisimmediatelythrownintothewater).4Specifications4.1Thesizeandshapeoftheelectromagneticstovepanelaresubjecttotherequirementdiagram.4.2DimensionsandtestmethodoftheproductaremeasuredinaccordancewiththedesignandtheVerniercaliper.4.3Theamountofdeformationiswithin1.0mm(intheprocessoftesting,theproductshouldbeplacedonthehorizontalplatform,andmeasuredbyapluggaugecoordinatedastandardruler.Onlyrulerisallowedtobeplaceontheplate.)4.4Theallowanceerrorofthicknessiswithin±0.5mm.4.5Theallowanceerrorofthestraightedgeiswithin±0.5mm.Thearcedgeissmooth,withoutbrokenandflangingedge.4.6TheRangleofproductiswithin±0.3mm.TheperpendicularityandparallelismispresentedinFigure1.aora’shouldbewithin1mm:3/8borb’shouldbewithin1mm:Edgecshouldbealongsidewiththerightangle.Figure15TheSpecificationofShape5.1Panel:brightanduniformcolorwithoutapparentsandinclusion,scratch,blotoredgebroken.5.2Screen-printing:thepatternandcolorareinaccordancewiththedesignforthecustomer.6PhysicalandChemicalPropertiesThereferenceofphysicalandchemicalpropertiesisinthefollowingtable:IndexofPhysicalandChemicalPropertiesItemIndex4/8ThermalShockResistanceNodeformationat760℃LinearExpansionCoefficient-1.5~+5×10-7/℃(0~700℃)Density(Specificgravity)2.55±0.02g/cm3Acidresistance<0.25mg/cm2Alkaliresistance<0.3mg/cm2ShockstrengthNodeformationunderspecifiedconditions(110mm)Moh’sstrength≥5.06.1ThermalProperties6.1.1HeatResistanceInnon-screenprintingcondition,nodeformationafter100hintheenvironmentof500℃.6.1.2ThermalShockResistanceHeatedfor30mininthetemperatureof760℃,nodeformationafterimmersioninwaterof20℃.6.1.3ThermalDeformationThethermalexpansioncoefficientoftheplatematerialis-1.5~+5×5/810-7/℃attherangeof30℃~700℃.Testingreference:GB/T16920-1997.Theheatingrateis5℃/mininthemediumofairoxygen.Testingequipment:NETZSCHDLL-402C.6.2MechanicalProperties6.2.1Moh’sStrengthTheMoh’sstrengthis6.5,undertheexecutionofterm6.5.4inJC/T.6.2.2ShockStrengthTestingisexecutedbythefollowingmechanicalstrengthtest.Theappearanceoftheplateremainsthesameafterthetesting.Products(testsample)isplacedinaccordancewiththatinFigure2.Threecontinuoushitswasexertedonthecenterpointoftestsamplebya525gsolidsteelballof50mmindiameter.6/8Figure26.3ChemicalProperties6.3.1AcidResistanceUndernon-screenprintingcondition,thecorrosionrateofglass-ceramicplateisunder0.25mg/cm2after24himmersionin5%hydrochloricacidsolutionat90℃.6.3.2AlkaliResistanceUndernon-screenprintingcondition,thecorrosionrateofglass-ceramicplateisunder0.3mg/cm2after24himmersionin5%sodiumcarbonatesolutionat90℃.7Screen-printingProperty...