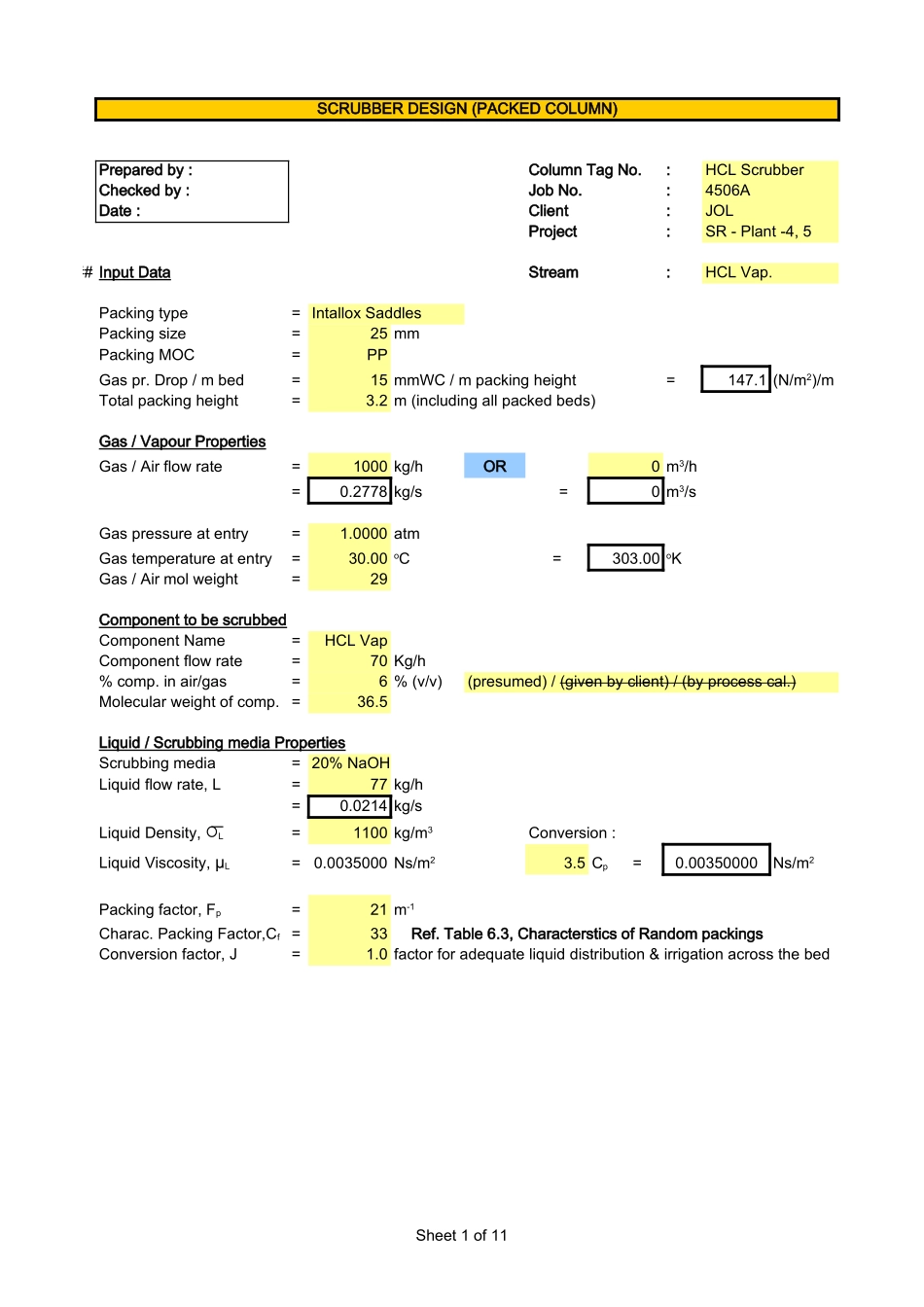

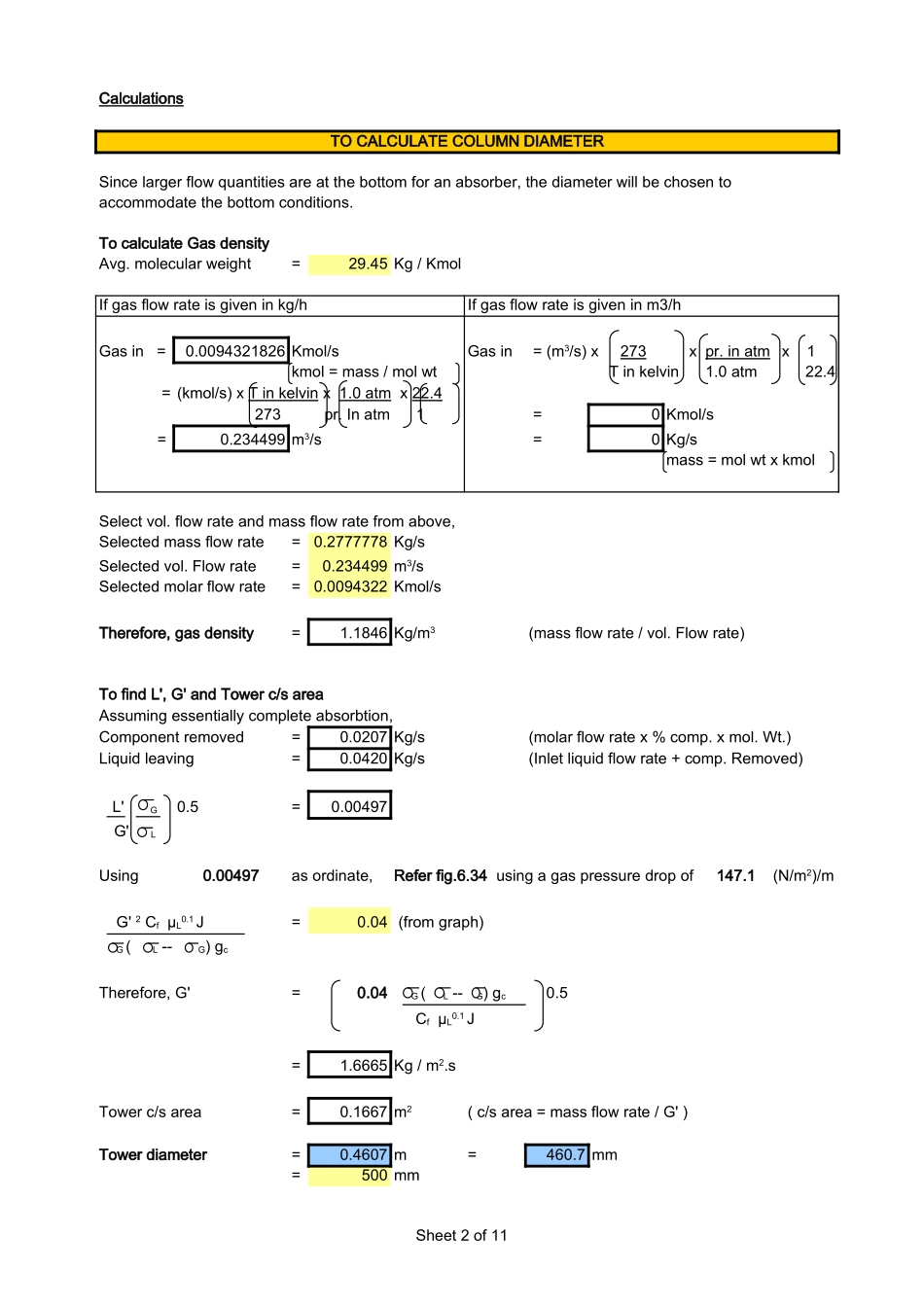

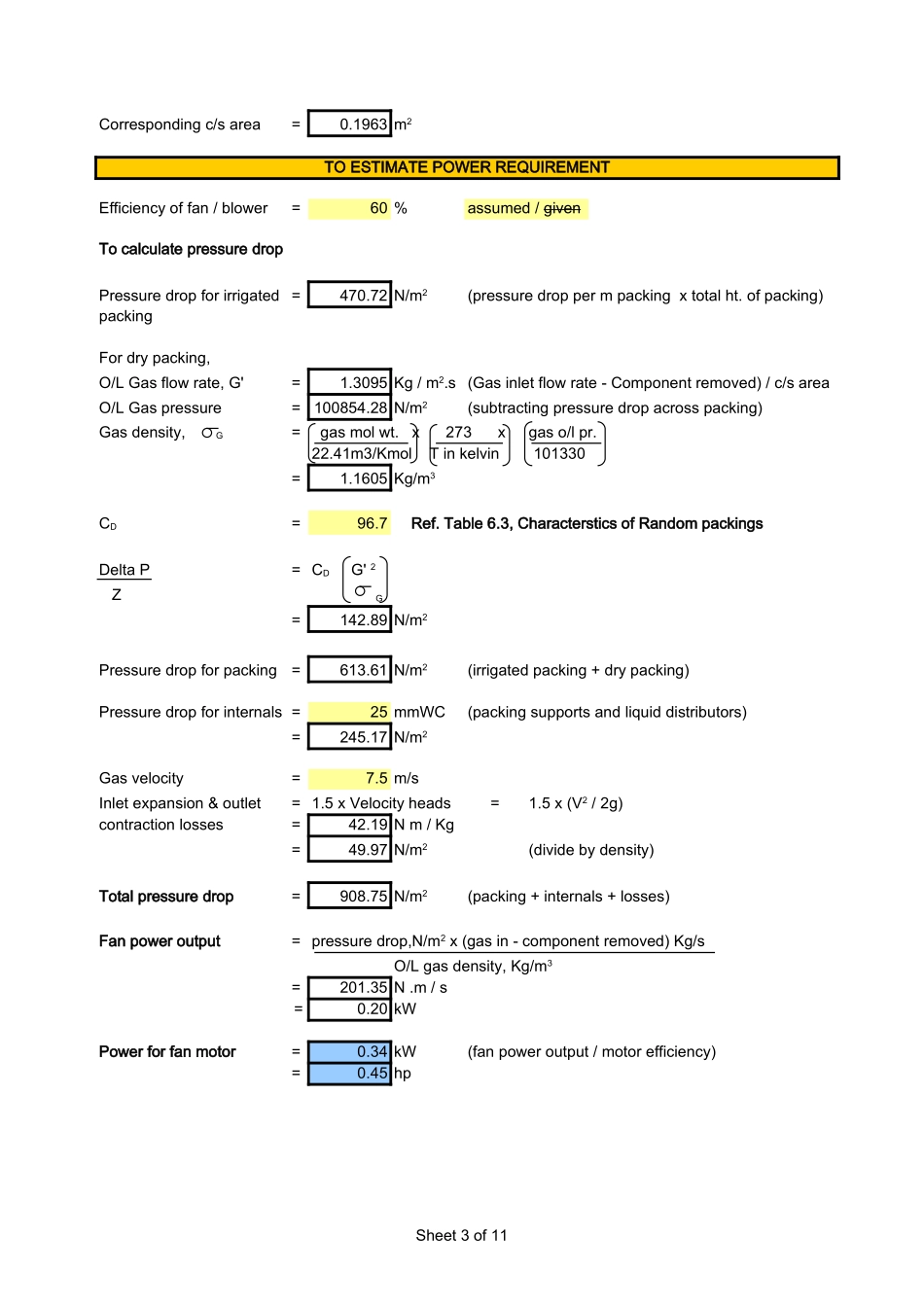

Sheet1of11SCRUBBERDESIGN(PACKEDCOLUMN)Preparedby:ColumnTagNo.:HCLScrubberCheckedby:JobNo.:4506ADate:Client:JOLProject:SR-Plant-4,5###InputDataStream:HCLVap.Packingtype=IntalloxSaddlesPackingsize=25mmPackingMOC=PPGaspr.Drop/mbed=15mmWC/mpackingheight=147.1Totalpackingheight=3.2m(includingallpackedbeds)Gas/VapourPropertiesGas/Airflowrate=1000kg/hOR0=0.2778kg/s=0Gaspressureatentry=1.0000atmGastemperatureatentry=30.00=303.00Gas/Airmolweight=29ComponenttobescrubbedComponentName=HCLVapComponentflowrate=70Kg/h%comp.inair/gas=6%(v/v)Molecularweightofcomp.=36.5Liquid/ScrubbingmediaPropertiesScrubbingmedia=20%NaOHLiquidflowrate,L=77kg/h=0.0214kg/s=1100Conversion:=0.00350003.50.00350000=21=33Ref.Table6.3,CharactersticsofRandompackingsConversionfactor,J=1.0factorforadequateliquiddistribution&irrigationacrossthebed(N/m2)/mm3/hm3/soCoK(presumed)/(givenbyclient)/(byprocesscal.)LiquidDensity,Lkg/m3LiquidViscosity,µLNs/m2Cp=Ns/m2Packingfactor,Fpm-1Charac.PackingFactor,CfSheet2of11CalculationsTOCALCULATECOLUMNDIAMETERSincelargerflowquantitiesareatthebottomforanabsorber,thediameterwillbechosentoaccommodatethebottomconditions.TocalculateGasdensityAvg.molecularweight=29.45Kg/KmolIfgasflowrateisgiveninkg/hIfgasflowrateisgiveninm3/hGasin=0.0094321826Kmol/sGasinxpr.inatmx1kmol=mass/molwtTinkelvin1.0atm22.4=273pr.Inatm1=0Kmol/s=0.234499=0Kg/smass=molwtxkmolSelectvol.flowrateandmassflowratefromabove,Selectedmassflowrate=0.2777778Kg/sSelectedvol.Flowrate=0.234499Selectedmolarflowrate=0.0094322Kmol/sTherefore,gasdensity=1.1846(massflowrate/vol.Flowrate)TofindL',G'andTowerc/sareaAssumingessentiallycompleteabsorbtion,Componentremoved=0.0207Kg/s(molarflowratex%comp.xmol.Wt.)Liquidleaving=0.0420Kg/s(Inletliquidflowrate+comp.Removed)0.5=0.00497Using0.00497asordinate,147.1=0.04(fromgraph)Therefore,G'=0.040.5=1.6665Towerc/sarea=0.1667(c/sarea=massflowrate/G')Towerdiameter=0.4607m=460.7mm=500mm=(m3/s)x273(kmol/s)xTinkelvinx1.0atmx22.4m3/sm3/sKg/m3L'GG'LReferfig.6.34usingagaspressuredropof(N/m2)/mG'2CfµL0.1JG(L--G)gcG(L--G)gcCfµL0.1JKg/m2.sm2Sheet3of11Correspondingc/sarea=0.1963TOESTIMATEPOWERREQUIREMENTEfficiencyoffan/blower=60%TocalculatepressuredropPressuredropforirrigated=470.72(pressuredroppermpackingxtotalht.ofpacking)packingFordrypacking,O/LGasflowrate,G'=1.3095(Gasinletflowrate-Componentremoved)/c/sareaO/LGaspressure=100854.28(subtractingpressuredropacrosspacking)=gasmolwt.x273xgaso/lpr.22.41m3/KmolTinkelvin101330=1.1605=96.7Ref.Table6.3,CharactersticsofRandompackingsDeltaP=Z=142.89Pressuredropforpacking=613.61(irrigatedpacking+drypacking)Pressuredropforinternals=25mmWC(packingsupportsandliquiddistributors)=245.17Gasvelocity=7.5m/sInletexpansion&outlet=1.5xVelocityheads=contractionlosses=42.19Nm/Kg=49.97(dividebydensity)Totalpressuredrop=908.75(packing+internals+losses)Fanpoweroutput==201.35N.m/s=0.20kWPowerforfanmotor=0.34kW(fanpoweroutput/motorefficiency)=0.45hpm2assumed/givenN/m2Kg/m2.sN/m2Gasdensity,GKg/m3CDCDG'2GN/m2N/m2N/m21.5x(V2/2g)N/m2N/m2pressuredrop,N/m2x(gasin-componentremoved)Kg/sO/Lgasdensity,Kg/m3Sheet4of11COLUMNDIAMETER/HYDRAULICCHECK==0.0025Designforaninitialpressuredropof15mmH2O/mpacking=0.85=6.50Trial%flooding==36.1620==3.7763Trialcolumnc/sarea==0.0736Trialcolumndia.,D=0.3060mD=Roundoff'D'toneareststandardsizeTherefore,D=0.500m=0.1963%flooding=13.5472ConclusionGenerallypackedtowersaredesignedfor50%--85%flooding.Iffloodingistobereduced,(i)Selectlargerpackingsizeandrepeattheabovesteps.OR(ii)Increasethecolumndiameterandrepeattheabovesteps.Liq.-Vap.Flowfactor,FLV(L/V)x(V/L)FromK4v/sFLV,K4K4atflooding((K4/K4atflooding))x100Gasmassflowrate,VmK4.V(L--V)13.1Fp(µL/L)0.1kg/m2.sV/Vm(TrialAs)m2(4/pi)xTrialAsColumnC/Sarea,Asm2As=(pi/4)xD2%flooding=Trial%floodingx(TrialAs/As)(1/2)Sheet5of11HETPPREDICTIONNorton'sCorrelation:lnHETP=n-0.187ln+0.213lnµApplicablewhen,liquidphasesurfacetension>4dyne/cm&<36dyne/cmliquidviscosity>0.08cP&<0.83cPConversion:InputData0.018N/m=18dyne/cmLiquid-phaseSurfaceTension,=20dyne/cmNorton'sCorrelationApplicableLiquidViscosity=3.5cPNorton'sCorrelationNOTapplicablen=1.13080CalculationlnHETP=0.8374366HETP=2.3104368ft=0.7042211mForseparations,lessthan15theoriticalstages,a20%designsafetyfactorcanbeapplied.Considering20%safetyfactor,HETP=0.8450653mForseparations,requiring15to25theoriticalstages,a15%designsafetyfactorcanbeapplied.Considering15%safetyfactor,HETP=0.8098543mTable6.2ConstantforHETPCorrelationRef.::RandomPackingsandPackedTowers----StrigleRef.::ChemicalEngineering,Volume-6,COULSON&RICHARDSON'SRef.::MassTransferOperation::Treybal