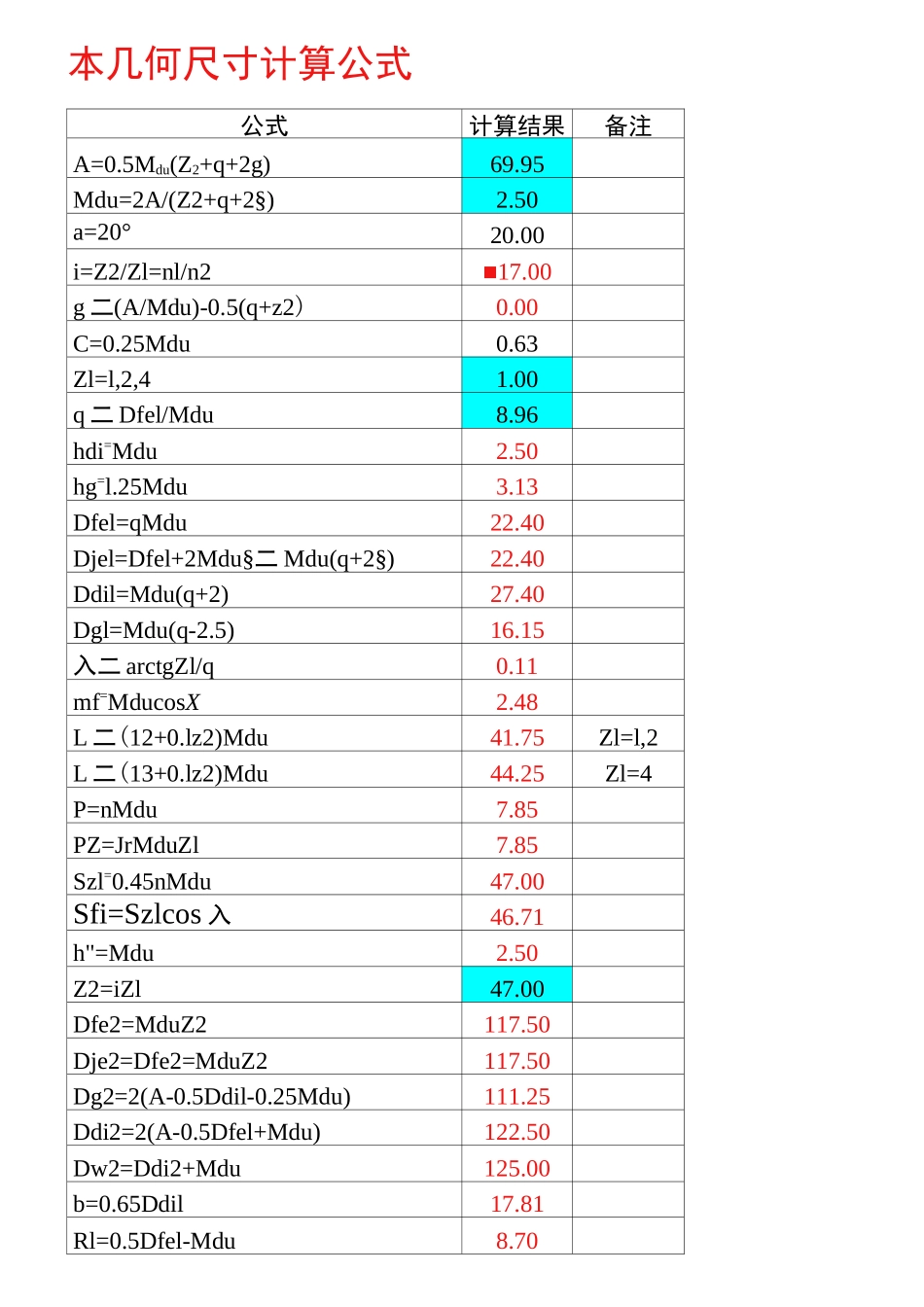

圆柱蜗杆传动基计算项目代号中心距A模数%轴截面齿形角a传动比•1变位系数g径向间隙c蜗杆头数Z1特性系数q齿顶高hdi齿根高hg分度圆直径Dfel节圆直径Djel齿顶圆直径Ddil齿根圆直径片分度圆螺旋导角X法向模数mf螺旋长度轴截面齿距P螺旋导程Pz尖糸刁mvr/Jcisi仕jLtrj扌出冋凶戸Szl嫁乃冷〃丿艾因仕jLtrj?厶冋凶Sfi齿厚测量高度蜗轮齿数Z2分度圆直径Dfe2节圆直径Dje2齿根圆直径%齿顶圆直径Ddi2最大外圆直径DW2轮缘宽度b齿顶圆弧半径Ri齿根圆弧半径注:☆磨削蜗杆需加长:MduW10时,加长25MM;10WMduW16时,加长35MM;Mdu>16时,加长40-50MM本几何尺寸计算公式公式计算结果备注A=0.5Mdu(Z2+q+2g)69.95Mdu=2A/(Z2+q+2§)2.50a=20°20.00i=Z2/Zl=nl/n2■17.00g二(A/Mdu)-0.5(q+z2)0.00C=0.25Mdu0.63Zl=l,2,41.00q二Dfel/Mdu8.96hdi=Mdu2.50hg=l.25Mdu3.13Dfel=qMdu22.40Djel=Dfel+2Mdu§二Mdu(q+2§)22.40Ddil=Mdu(q+2)27.40Dgl=Mdu(q-2.5)16.15入二arctgZl/q0.11mf=MducosX2.48L二(12+0.lz2)Mdu41.75Zl=l,2L二(13+0.lz2)Mdu44.25Zl=4P=nMdu7.85PZ=JrMduZl7.85Szl=0.45nMdu47.00Sfi=Szlcos入46.71h"=Mdu2.50Z2=iZl47.00Dfe2=MduZ2117.50Dje2=Dfe2=MduZ2117.50Dg2=2(A-0.5Ddil-0.25Mdu)111.25Ddi2=2(A-0.5Dfel+Mdu)122.50Dw2=Ddi2+Mdu125.00b=0.65Ddil17.81Rl=0.5Dfel-Mdu8.70R1=O.5Ddil+0.25Mdu14.33(JB2318-79)