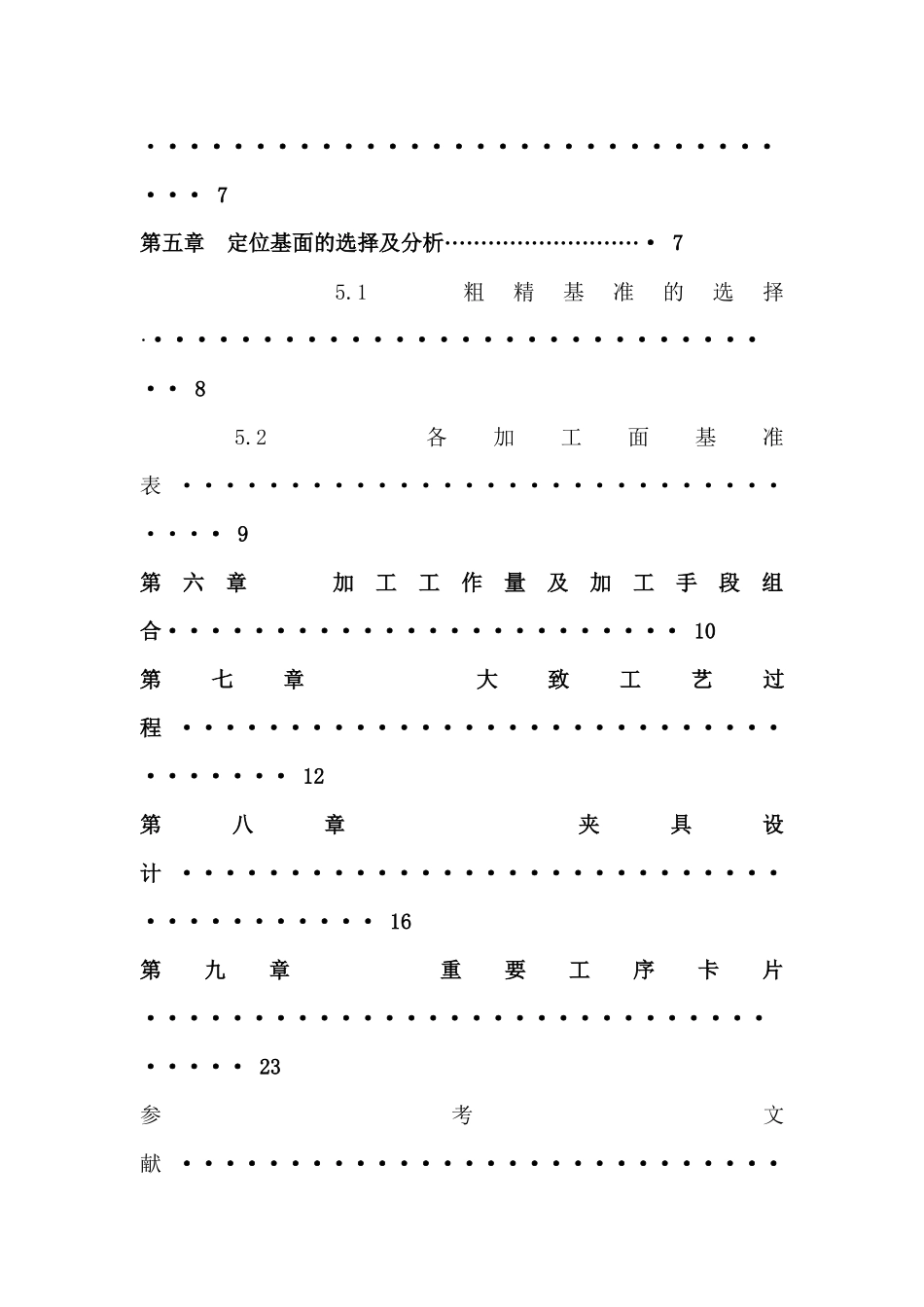

目 录第一章 产品概述········································ 2第二章 箱体的工艺分析 ································· 4 2.1图纸的错误及修改 ································· 4 2.2 图纸的技术要求分析······························· 4第三章 生产纲领 ········································ 5第四章 材料的选择和毛坯的制造方法的选择及毛坯图·· 5 4.1 材料选择 ····································· 5 4.2 毛坯制造方法的选择 ··························· 6 4.3 毛坯图的绘制 ································ 7 第五章 定位基面的选择及分析···························· 7 5.1 粗精基准的选择 ······························· 8 5.2 各加工面基准表 ································ 9 第六章 加工工作量及加工手段组合························ 10第七章 大致工艺过程 ··································· 12第八章 夹具设计 ······································· 16第九章 重要工序卡片 ·································· 23参考文献 ··············································· 24实习心得 ············································· 24附件 第一章 产品概述箱体是减速器(如图 1-1)中所有零件的基座,是支撑和固定轴系部件、保证传动零件的正确相对位置并承受作用在减速器上载荷的重要零件,在整个减速器总成中的起支撑和连接的作用,它把各个零件连接起来,支撑传动轴,保证各传动机构的正确安装。箱体一般还兼做润滑油的油箱,具有充分润滑和良好密封箱内零件的作用。 1-1 单级锥齿轮减速箱结...