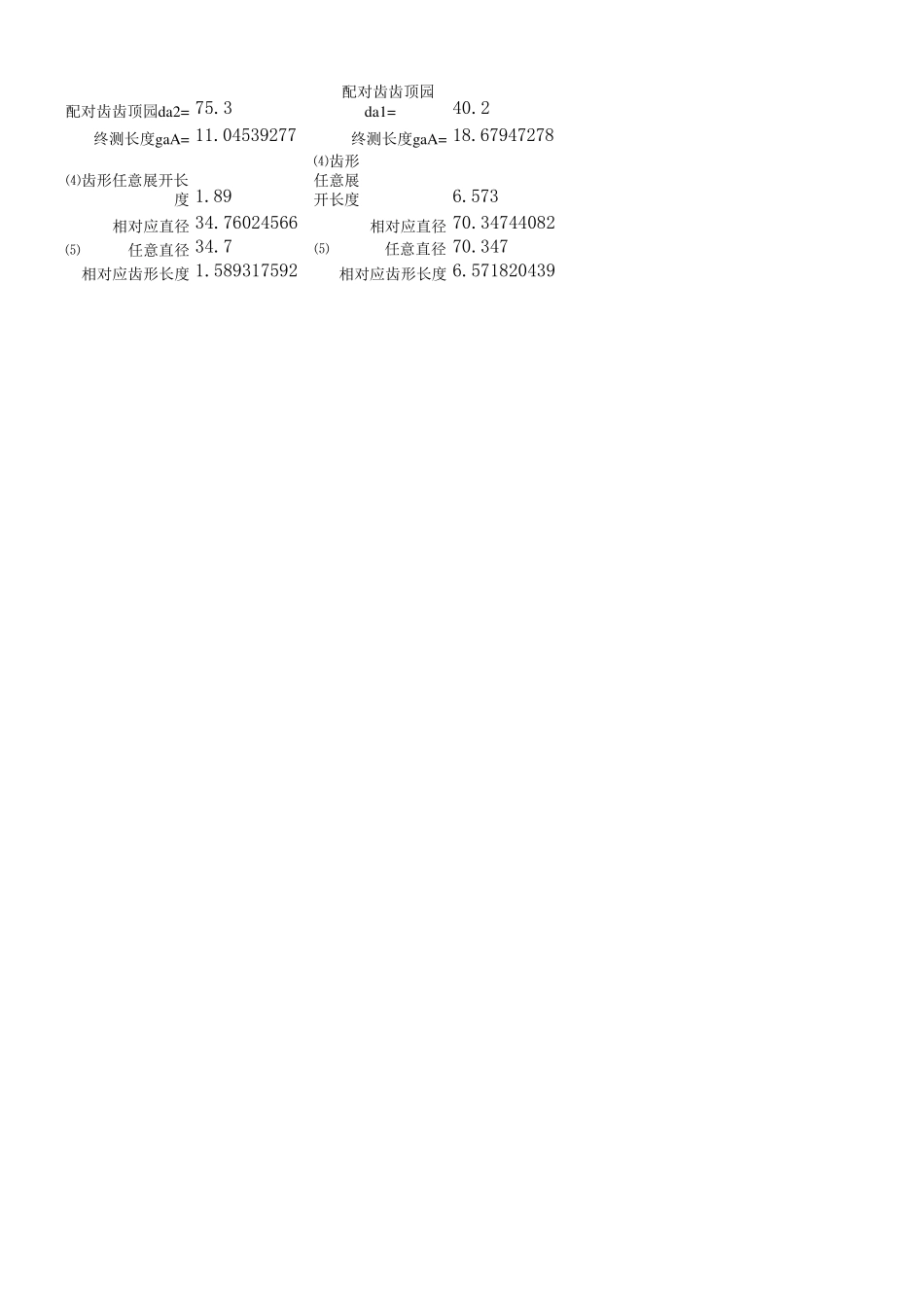

模数Mn= 1.5齿数Z1= 22分度圆压力角an= 20有效齿宽= 10变位系数x n1= 0.1齿数Z2= 44螺旋角B= 28顶隙系数C1*= 0.35变位系数x n2= -0.122.402523651.101316473 实际中心距ɑ= 54.50.4122217870.35 啮合角at′-0.1863899821.158945916 inv at′= 0.014606348-0.211099711 重合度齿顶圆压力角aat1= 32.5911876 at′= 19.8702059955.74556794齿顶圆压力角aat2= 28.39504347 重合度§=3.224061649齿顶圆直径da1= 41.0120602378.55976023滑动率η1= 176.3368958 齿根圆直径df1= 33.3208622570.5227856η2= 1.873879753 分度圆直径 d1= 37.3748116774.74962335 基圆直径db1= 34.5541065369.1082130716.0891 节圆直径d1′= 37.1637119674.327423924 分度圆弧齿厚Sn1= 2.465385562.4653855622任意弧齿厚Sx = 1.1674811772.250143179-0.06602229弧齿厚所对压力角= 30.7333574823.397528822.284104045弧齿厚所对直径dx = 40.275.3 公法线W1= 16.259448925.5687839542.23505 K1= 4.1507478837.2841795753实取跨齿数K= 4622 当量齿数Z'1=31.3282149962.6564299834.55410653 M值 M1= 42.6290225879.619009528.27370314 inv amt1= 0.0498764090.0322413790.880694852 amt1= 29.3152005125.58147868-0.0660dp1= 2.1114925332.3167046192.284117127 实取量棒径dp1= 3322Z1为奇数齿M值M1= 42.5280523779.5701898328.54393764 齿形展开长度0.878450942(1) 起测长度gaA= 0.267919027.901999032-0.0243(2) 起测长度gaA= 0.267919027.9019990322.329654488配对齿齿顶倒棱C= 00(3) 起测长度gaA= 3.9962640298.675418747 齿轮齿数Z1或Z2=已知公法线W=跨测齿数K=2) 分度园齿厚Sn=Ⅱ. 已知M值求变位系数、分度园齿厚配对齿轮参数计算1齿顶高系数ha1*= 顶隙系数C2*=齿顶高系数ha2*=量棒直径dp= 1)齿数(偶数)Z1或Z2=基园直径db= 量棒接触角αmt=M值=1) 变位系数Xn=基圆直径db2=分度圆直径d2= 量棒接触角αmt=cosαmt=变位系数Xn=分园齿厚(奇)Sn=cosαmt=变位系数Xn=分园齿厚(偶)Sn= 2)齿数(奇数)Z1或Z2=Ⅰ. 已知公法线求变位系数、分度园齿厚齿轮 1 齿轮 2弧齿厚所对直径dx =弧齿厚所对压力角=任意弧齿厚Sx =分度圆弧齿厚Sn2=节圆直径d2′=(2) 起测长度gaA=(1) 起测长度gaA=齿形展开长度Z2为奇数齿M值M2= 配对齿齿顶倒棱C=(3) 起测长度gaA=M值M2=当量齿数Z'2=K2=公法线W2=实取跨...