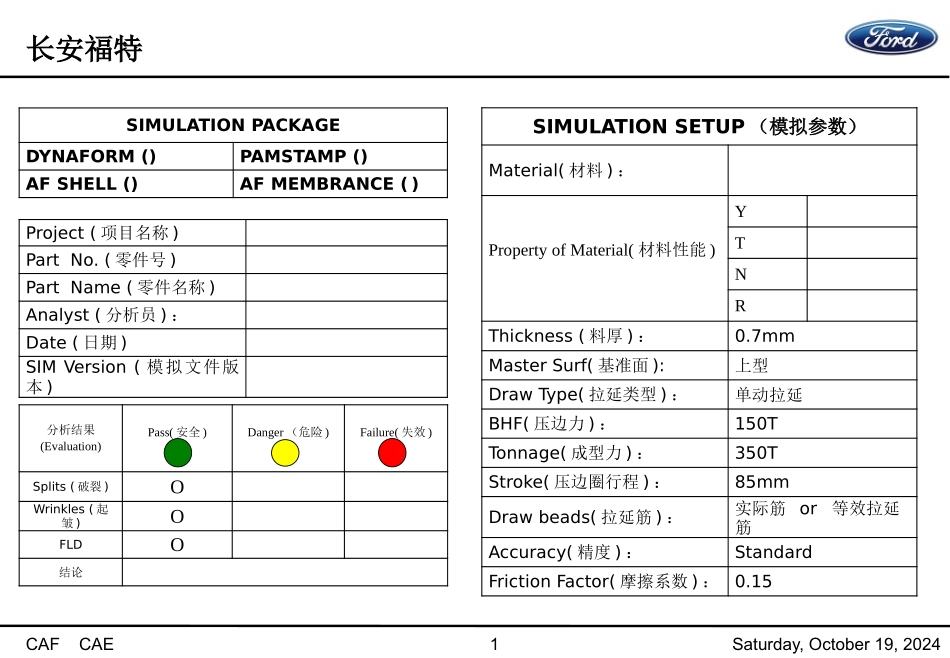

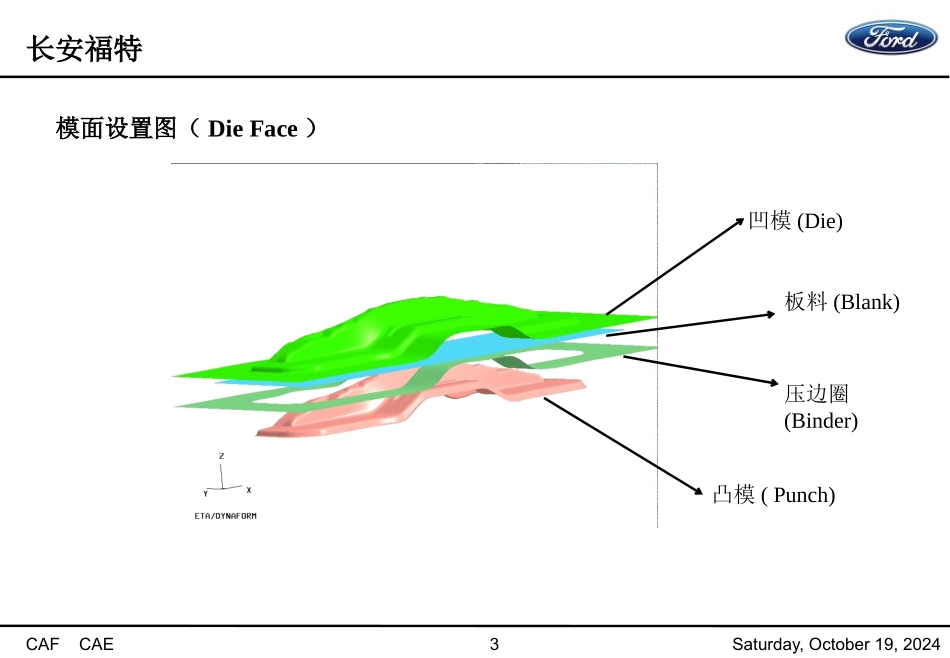

CAFCAE1Saturday,October19,2024长安福特Project(项目名称)PartNo.(零件号)PartName(零件名称)Analyst(分析员):Date(日期)SIMVersion(模拟文件版本)SIMULATIONPACKAGEDYNAFORM()PAMSTAMP()AFSHELL()AFMEMBRANCE()SIMULATIONSETUP(模拟参数)Material(材料):PropertyofMaterial(材料性能)YTNRThickness(料厚):0.7mmMasterSurf(基准面):上型DrawType(拉延类型):单动拉延BHF(压边力):150TTonnage(成型力):350TStroke(压边圈行程):85mmDrawbeads(拉延筋):实际筋or等效拉延筋Accuracy(精度):StandardFrictionFactor(摩擦系数):0.15分析结果(Evaluation)Pass(安全)Danger(危险)Failure(失效)Splits(破裂)OWrinkles(起皱)OFLDO结论CAFCAE2Saturday,October19,2024长安福特NestingandSHAPEOFTHEBLANK(坯料及排样图)方料Rectangle梯形料Trapezium形状料Shape4644401357345单位:mm下料尺寸:1357*800/2材料利用率:55%CAFCAE3Saturday,October19,2024长安福特模面设置图(DieFace)凹模(Die)板料(Blank)压边圈(Binder)凸模(Punch)CAFCAE4Saturday,October19,2024长安福特INFLOW(流入量分布图)&Trimline注:必须显示修边线位置或则最后零件轮廓线。CAFCAE5Saturday,October19,2024长安福特等效拉延筋位置(Drawbeads)CAFCAE6Saturday,October19,2024长安福特ThinningRatioAnalysis(坯料减薄率分布图)注:破裂起皱区域要显示出来零件最大减薄率(或则最大厚度)云图分级显示零件增厚率(或则最小厚度)CAFCAE7Saturday,October19,2024长安福特WrinkleAnalysis:Meanstress(平均应力分布图:起皱判断)最大值为材料屈服强度最小值为负的材料抗拉强度云图8级显示,红色表示起皱风险极高,黄色表示有一定风险。注:仅对DYNAFORMCAFCAE8Saturday,October19,2024长安福特WrinklingCriterionPlot(起皱趋势)注:仅对AUTOFORMCAFCAE9Saturday,October19,2024长安福特FormingLimitDiagram成型极限图(必须显示出零件有起皱和破裂的区域)FLD图必须显示清晰,且对于DYNAFORM,必须在此页注明FLD0值。FLD安全裕度推荐10%-20%FLD0:0.35CAFCAE10Saturday,October19,2024长安福特Formingprocess:Theblankgravity(重力状态)CAFCAE11Saturday,October19,2024长安福特Thebinderclosing(压边圈闭合)CAFCAE12Saturday,October19,2024长安福特85mmtothedrawhome75mmtothedrawhomeCAFCAE13Saturday,October19,2024长安福特65mmtothedrawhome55mmtothedrawhomeCAFCAE14Saturday,October19,2024长安福特45mmtothedrawhome35mmtothedrawhomeCAFCAE15Saturday,October19,2024长安福特25mmtothedrawhome15mmtothedrawhomeCAFCAE16Saturday,October19,2024长安福特5mmtothedrawhomehome注:压边圈闭合位置以及到底前3-5mm位置必须显示!CAFCAE17Saturday,October19,2024长安福特回弹分析结果Springbackresult:(显示回弹量和断面截图)(Shownthespringbackandsectionpic)(本页只需招标完成后开模之前提交)CAFCAE18Saturday,October19,2024长安福特附页供应商可自行填入其他重要内容,包括结论以及改进方案等