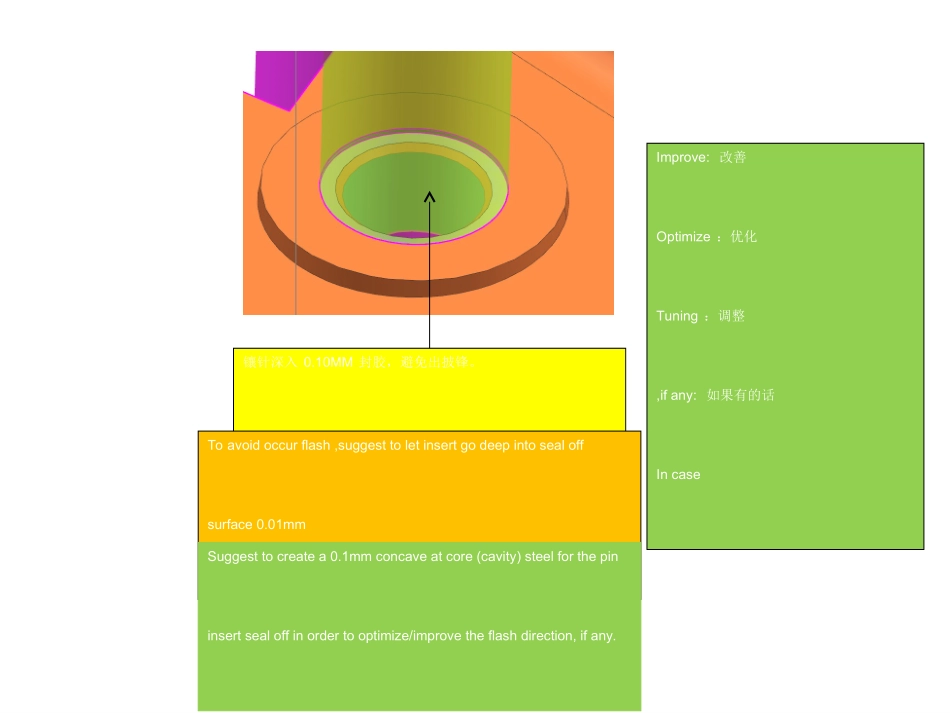

产品1:这个产品还有一件镜像体,这里不重复分析。70.672.64Part1:RHandLHismirroredsoonlyoneofitisshowninthisreport.注意,本文件底色绿色部分的翻译文本为比较合适的表述效果。镶针深入0.10MM封胶,避免出披锋。Toavoidoccurflash,suggesttoletinsertgodeepintosealoffsurface0.01mmSuggesttocreatea0.1mmconcaveatcore(cavity)steelforthepininsertsealoffinordertooptimize/improvetheflashdirection,ifany.Improve:改善Optimize:优化Tuning:调整,ifany:如果有的话Incase0.1MM前后模镶针碰穿,避免出现段差,前模镶针比后模镶针做大0.1MM.Duetocoreinsertpinshuttingoff,suggesttomakethesizeofcavityinsertpinbiger0.1mmthancoreinsertpinsizetoavoidoccurlevermarkThereisshutoffbetweencorepins,wesuggesttomakecavitysidecorepin0.1mmbigger.如图,红色部分出前模,产品减胶0.05MMIndicatedredsurfaceforcavity,suggesttoremovematerial0.05mm分型面与骨位底面平行PLsurfacebeparalleltothebottomsurfaceofribThesurfacesinredisformedbythecavitywhichneedtocreatepositivedraftbyremovingmaterial,max.0.05mmPositive:正面的Negative:负面的Draft:出模角MMC:MaximumMaterialConditionPartinglinewillbeinparalleltothebottomsurfacethisrib.所指红色面直身,建议往前模加胶拨模2度,最大加胶0.06MM详见修改后的产品3D所指红色面倒扣,建议往前模拨模0.3度,最大加胶0.19MM详见修改后的产品3D所指红色面倒扣,建议往前模加胶拨模2度,最大减胶0.13MM详见修改后的产品3DIndicatedredsurfacewithoutdraftangle,suggesttoapply2degreeatthecavityside,max.materialaddedis0.06mm,moredetailsrefertomodifiedpart3DIndicatedredsurfaceisundercut,suggesttoapply0.3degreeatthecavitysidebyaddingmaterial,max.materialaddedis0.19mm,moredetailsrefertomodifiedpart3DIndicatedredsurfaceisundercut,suggesttoapply2degreeatthecavitysidebyremovingmaterial,max.materialremovalis0.19mm,moredetailsrefertomodifiedpart3DThereisnodraftintheredsurfaces,suggesttoapply2degreeincavitydirectionbyaddingmaterial,max.materialaddedis0.06mm,pleaserefertopart3Ddataupdated/modifiedbyus.Update:升级Modify:更改Latest=updated:最新Undercutinredsurfaceasindicated….所指红色面倒扣,建议往行位减胶拨模2度,最大减胶0.05MM详见修改后的产品3D为避免行位薄钢建议所指红色面加胶到行位分型面,最大加胶0.09MM详见修改后的产品3D为避免行位薄钢建议所指红色面加胶到行位分型面,最大加胶0.05MM详见修改后的产品3DSuggesttoaddmaterialintoparallelwithPLtoavoidslidetoothin,max.materialaddedis0.09mm,moredetailsrefertomodifiedpart3DIndicatedredsurfaceisundercut,suggesttoapply2degreeatthecavitysidebyremovingmaterial,max.materialremovalis0.05mm,moredetailsrefertomodifiedpart3DSuggesttoaddmaterialintoparallelwithPLtoavoidslidetoothin,max.materialaddedis0.05mm,moredetailsrefertomodifiedpart3DThinsteelconditioninslideatredsurfaces,suggesttoincreasematerialtolevelupthesurfacetopartingline,max.materialaddedis0.09mm,pleaserefertotheupdateddataforyourapproval.LevelupForyourapproval.6.1Theinsertistoosmall,whickisnospacetomakewater-line,soweproposetoapplythematerialismadeofBeCu.后模镶件太小,运水无法到达胶位上面Thisinsertistoosmalltoapplywaterline,wesuggesttoapplyBeCuforbettercooling.0.5修改前修改后0.522第2色Itisonly0.5mmsteeltosealing-offthatistoothin,proposetoincreaseanother1.5mmminimum(theredsurface)asindicated,Thenthesteelthicknessbecomes2mmforsealing.2ndshotBeforeAfter如图示第二色红色面处出行位(如下图)封胶面出现薄钢(0.5mm)影响第二色行位封胶钢料强度,建议此处红色面处减胶由0.5mm变更至2mm,OK?Thereis0.5mmsteelforseal-offwhichistoothin,proposetoincrease1.5mmmin.asind...