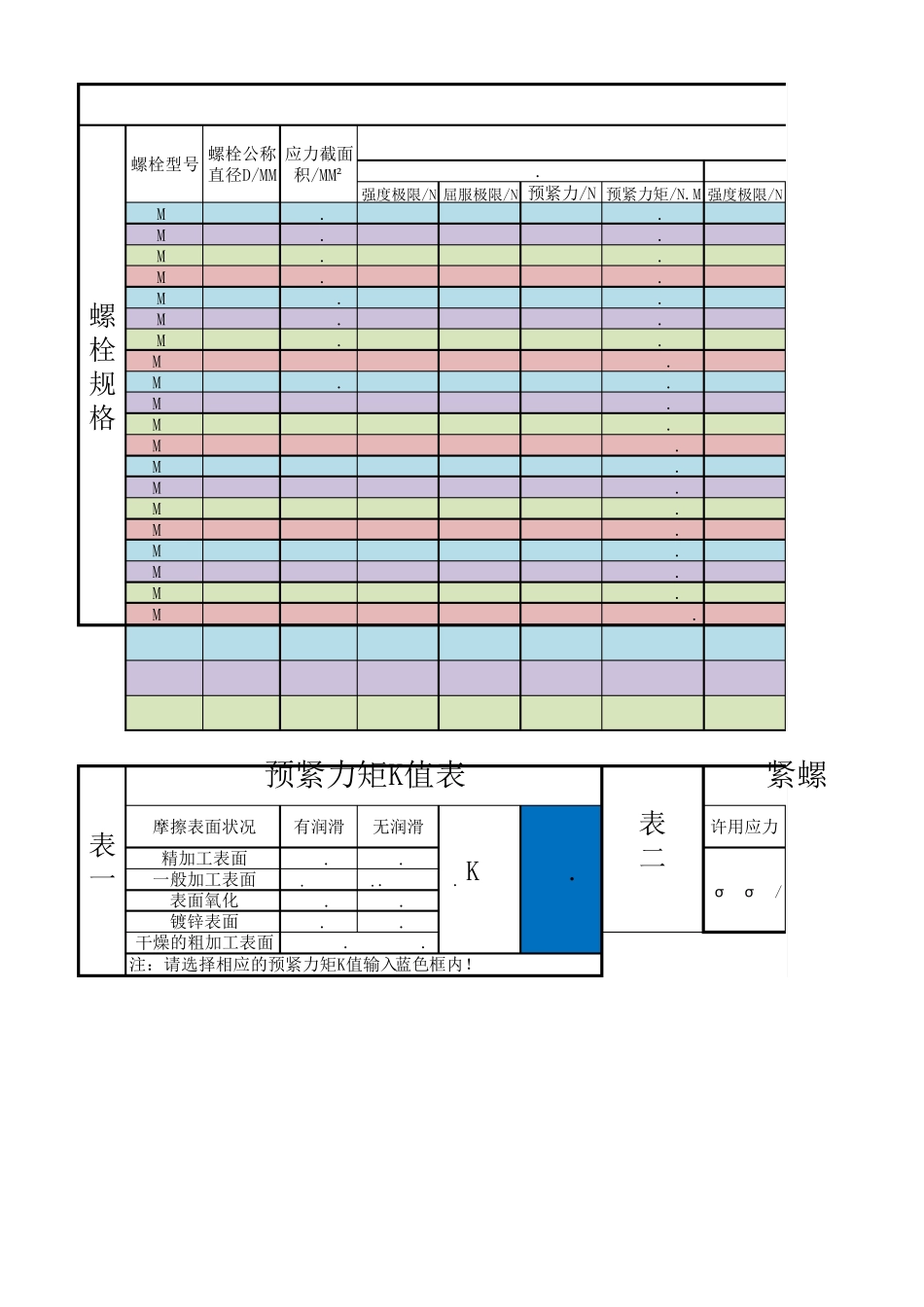

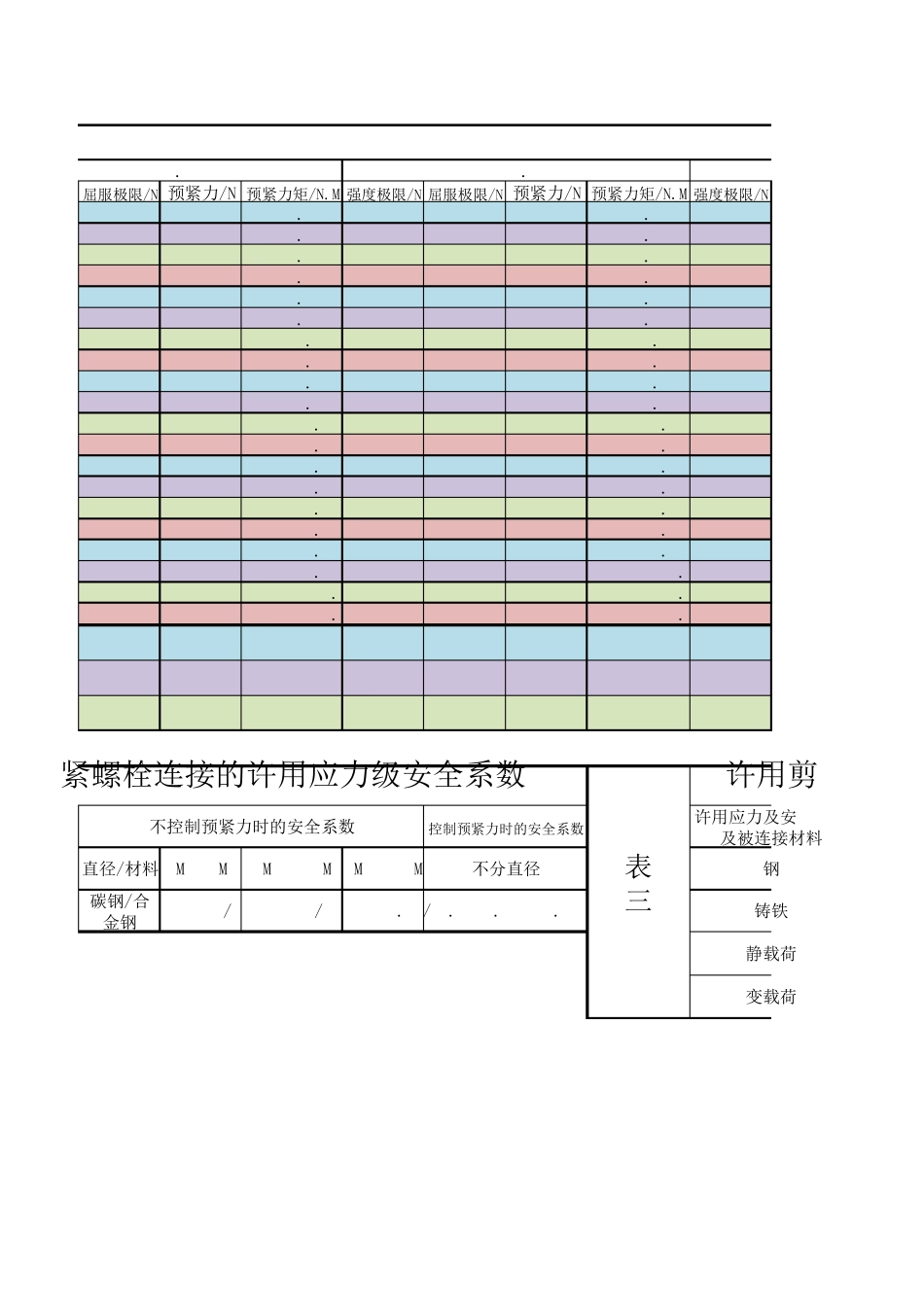

强度极限/N 屈服极限/N 预紧力/N 预紧力矩/N.M 强度极限/NM110.4613883500.0149 184M222.076213732240.1341 828M335.031,509 9055430.48892,012M448.782,6341,580 9481.13793,512M5514.24,2602,5561,534 2.30045,680M6620.16,0303,6182,171 3.90748,040M8836.6 10,9806,5883,953 9.486714,640M10105817,40010,4406,26418.792023,200M121284.3 25,29015,1749,10432.775833,720M141411534,50020,70012,42052.164046,000M161615747,10028,26016,95681.388862,800M181819257,60034,56020,736111.974476,800M202024573,50044,10026,460158.760098,000M222230390,90054,54032,724215.9784121,200M2424353 105,90063,54038,124274.4928141,200M2727459 137,70082,62049,572401.5332183,600M3030561 168,300100,98060,588545.2920224,400M3333694 208,200124,92074,952742.0248277,600M3636817 245,100147,06088,236952.9488326,800M3939976 292,800175,680105,4081,233.2736390,4000.10.120.13-0.150.18-0.210.20.240.180.22预紧力矩K值表螺栓型号应力截面积/MM²螺栓规格螺栓公称直径D/MM3.6表一许用应力[σ ]=σ s/S有润滑无润滑0.26-0.3K=0.3摩擦表面状况精加工表面一般加工表面表面氧化镀锌表面注:请选择相应的预紧力矩K值输入蓝色框内!干燥的粗加工表面表二紧螺屈服极限/N 预紧力/N 预紧力矩/N.M 强度极限/N 屈服极限/N 预紧力/N 预紧力矩/N.M 强度极限/N110660.0199 184147880.0265 2304972980.1788 8286623970.23851,0351,207 7240.65192,0121,610 9660.86922,5152,1071,264 1.51723,5122,8101,686 2.02294,3903,4082,045 3.06725,6804,5442,726 4.08967,1004,8242,894 5.20998,0406,4323,859 6.946610,0508,7845,27012.649014,64011,7127,02716.865318,30013,9208,35225.056023,20018,56011,13633.408029,00020,23212,13943.701133,72026,97616,18658.268242,15027,60016,56069.552046,00036,80022,08092.736057,50037,68022,608108.518462,80050,24030,144144.691278,50046,08027,648149.299276,80061,44036,864199.065696,00058,80035,280211.680098,00078,40047,040282.2400122,50072,72043,632287.9712121,20096,96058,176383.9616151,50084,72050,832365.9904141,200112,96067,776487.9872176,500110,16066,096535.3776183,600146,88088,128713.8368229,500134,64080,784727.0560224,400179,520107...