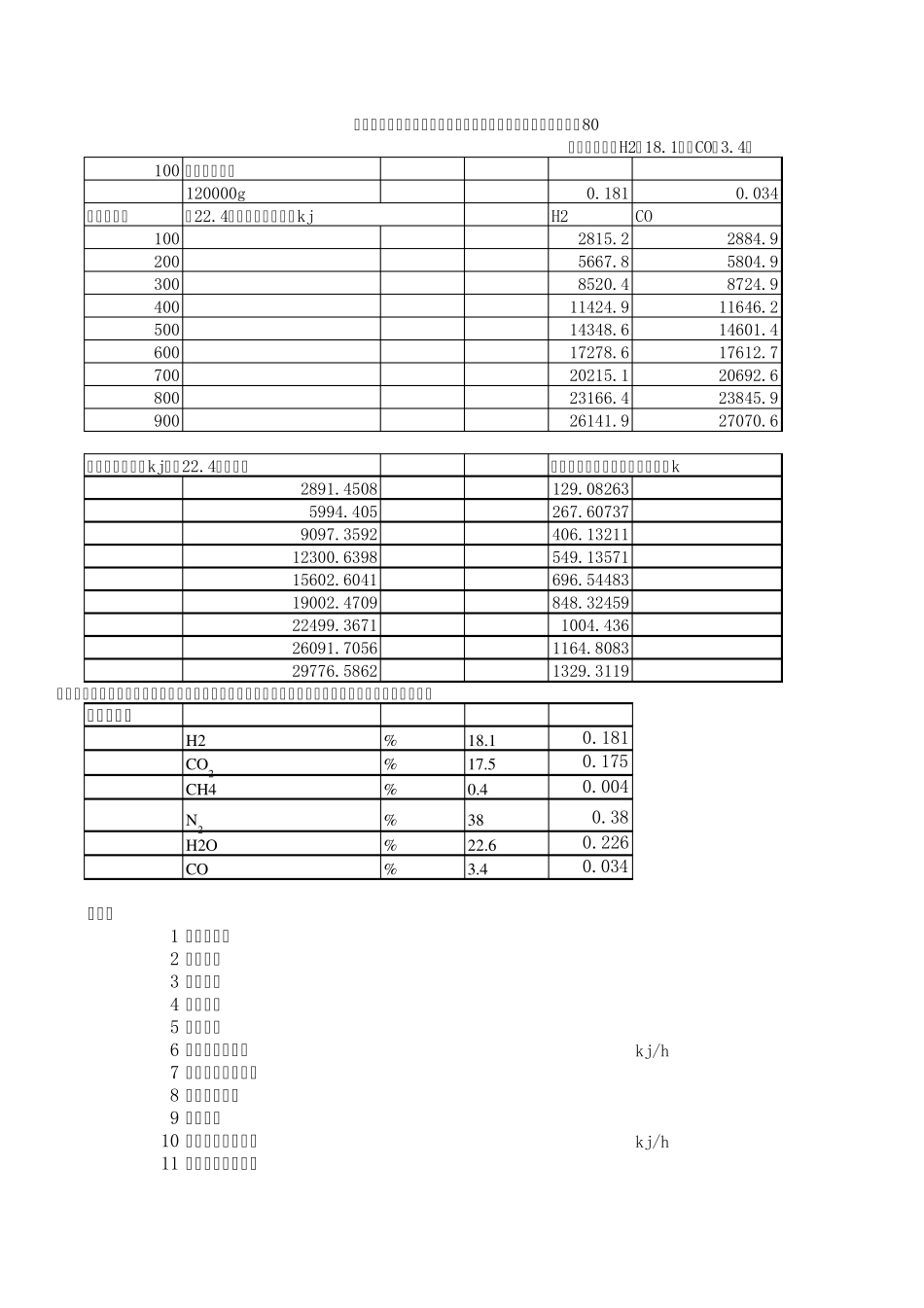

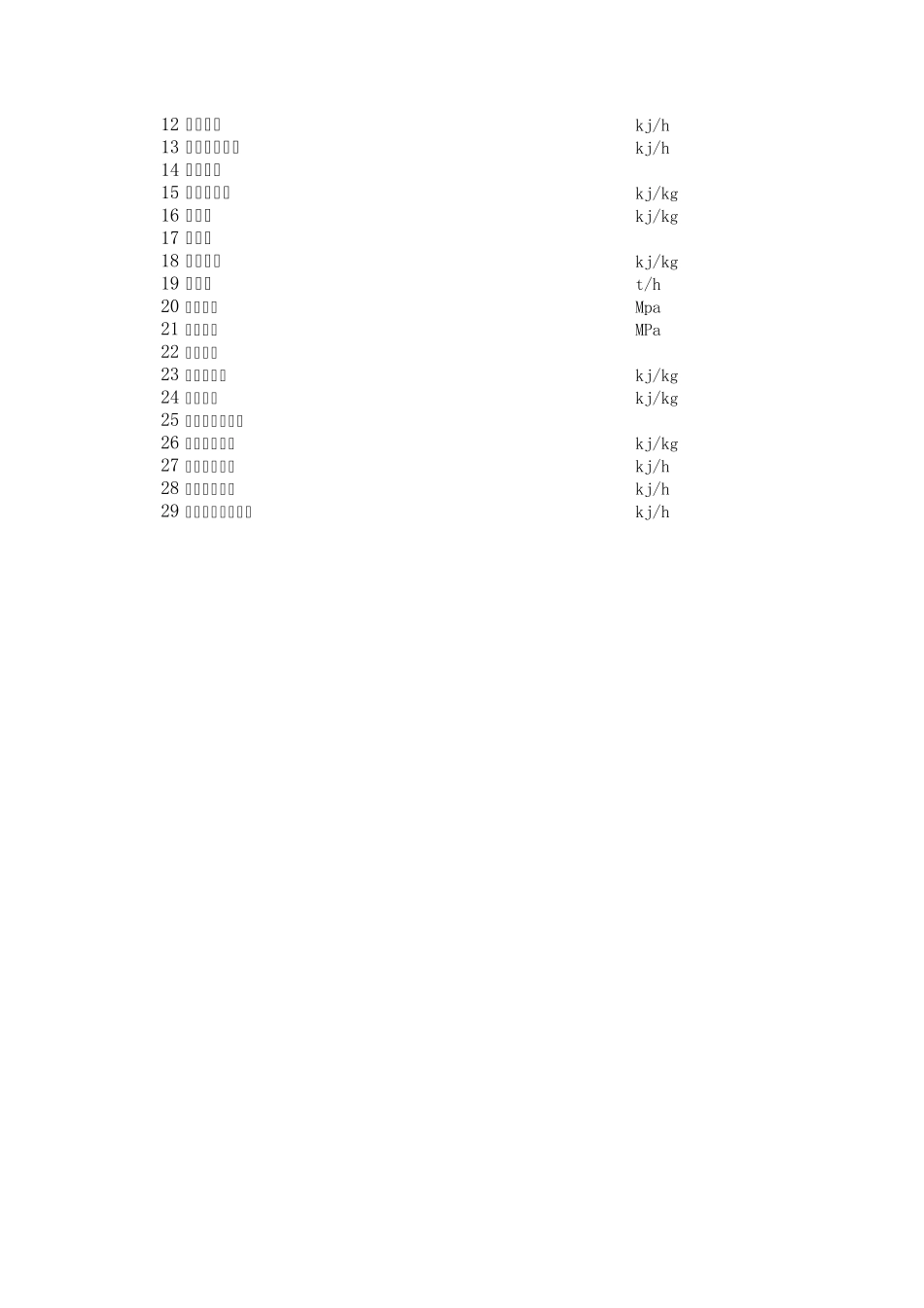

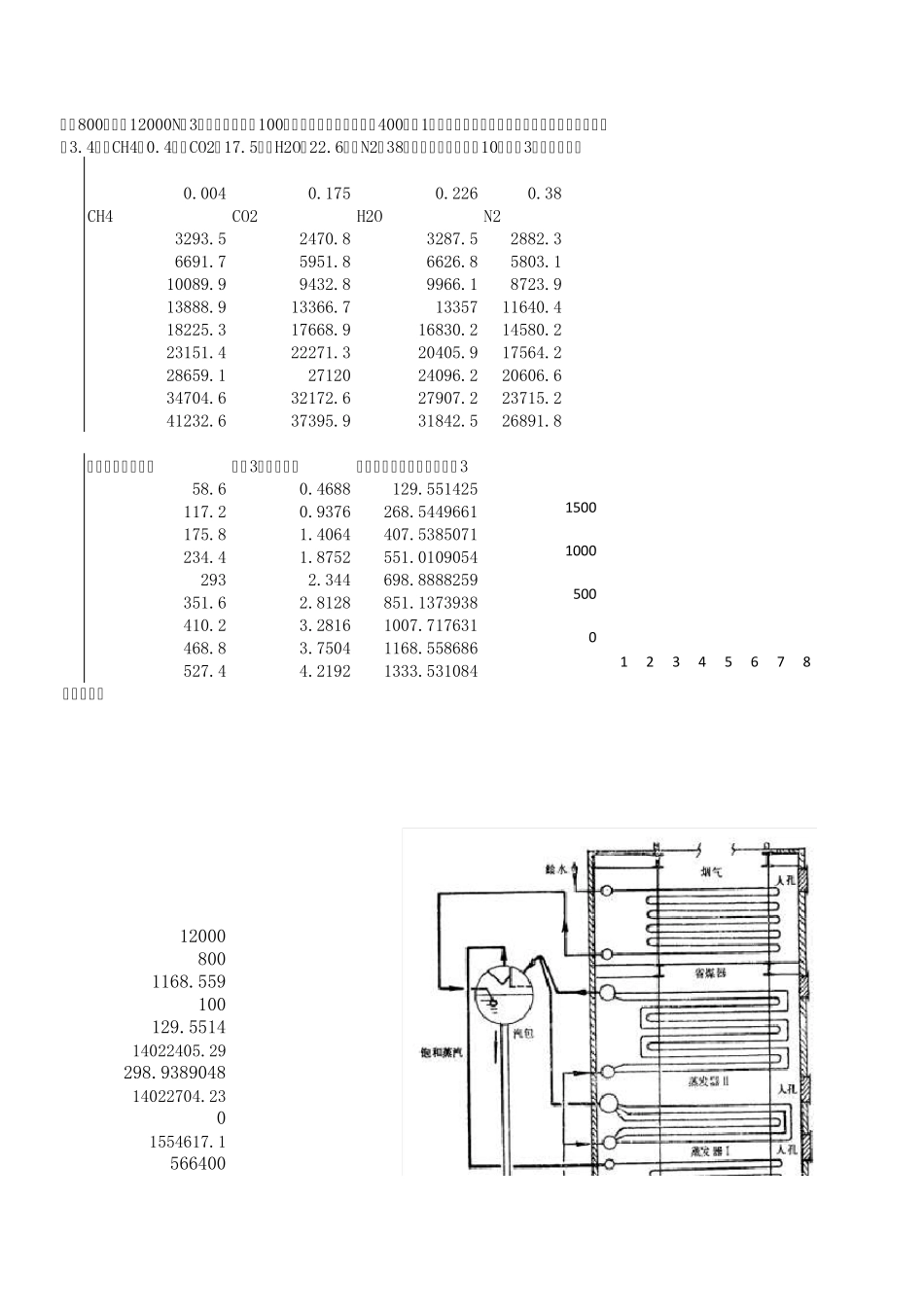

100 一小时含尘量120000g0.1810.034水煤气温度每22.4立方米水煤气焓值kjH2CO1002815.22884.92005667.85804.93008520.48724.940011424.911646.250014348.614601.460017278.617612.770020215.120692.680023166.423845.990026141.927070.6水煤气理论焓值kj(每22.4立方米)水煤气理论焓值(不含灰的焓)k2891.4508129.082635994.405267.607379097.3592406.1321112300.6398549.1357115602.6041696.5448319002.4709848.3245922499.36711004.43626091.70561164.808329776.58621329.3119出,由于水煤气温度低,炉口辐射热量忽略,采用全密封结构,,锅炉漏风系数很小,暂忽略漏风损烟气成分:H2%18.10.181CO2%17.50.175CH4%0.40.004N2%380.38H2O%22.60.226CO%3.40.034热平衡1 进炉烟气量2 入炉烟温3 入炉烟焓4 出炉烟温5 出炉烟焓6 烟气带入热功率kj/h7 烟尘带入的热功率8 入炉总热功率9 漏风系数10 烟气带走的热功率kj/h11 烟尘带走的热功率水煤气成分 H2 18.1% CO 3.4%命题:余热回收利用 煤化工 水煤气余热去加热水蒸气 8012 散热损失kj/h13 汽化吸热功率kj/h14 给水温度15 过热蒸汽焓kj/kg16 给水焓kj/kg17 排污率18 饱和水焓kj/kg19 产汽量t/h20 给水压力Mpa21 锅筒压力MPa22 饱和温度23 饱和蒸汽焓kj/kg24 饱和水焓kj/kg25 省煤器出口水温26 省煤器出口焓kj/kg27 过热器吸热量kj/h28 省煤器吸热量kj/h29 蒸发受热面吸热量kj/h0.0040.1750.2260.38CH4CO2H2ON23293.52470.83287.52882.36691.75951.86626.85803.110089.99432.89966.18723.913888.913366.71335711640.418225.317668.916830.214580.223151.422271.320405.917564.228659.12712024096.220606.634704.632172.627907.223715.241232.637395.931842.526891.8灰的焓kj/kg每m3灰的焓kj水煤气的理论焓值kj/m358.60.4688129.551425117.20.9376268.5449661175.81.4064407.5385071234.41.8752551.01090542932.344698.8888259351.62.8128851.1373938410.23.28161007.717631468.83.75041168.558686527.44.21921333.531084漏风损失,120008001168.559100129.551414022405.29298.938904814022704.2301554617.1566400 3.4% CH4 0.4% CO2 17.5% H2O 22.6% N2 38% 热值 含尘量10g/m3 经济型分析气 800℃ 12000Nm3/h 冷却到100℃ 另一工艺需水蒸气400℃ 1MPa 设计换热器 蒸汽流量? 常规水0500100015001234567814022.7042312454064.420.888135713203214.58502782.053.869570035 无排污1.24481.18180.60722782.05794.8475170.60727181720965.0622519067.8328214031.531常规水20℃89系列1