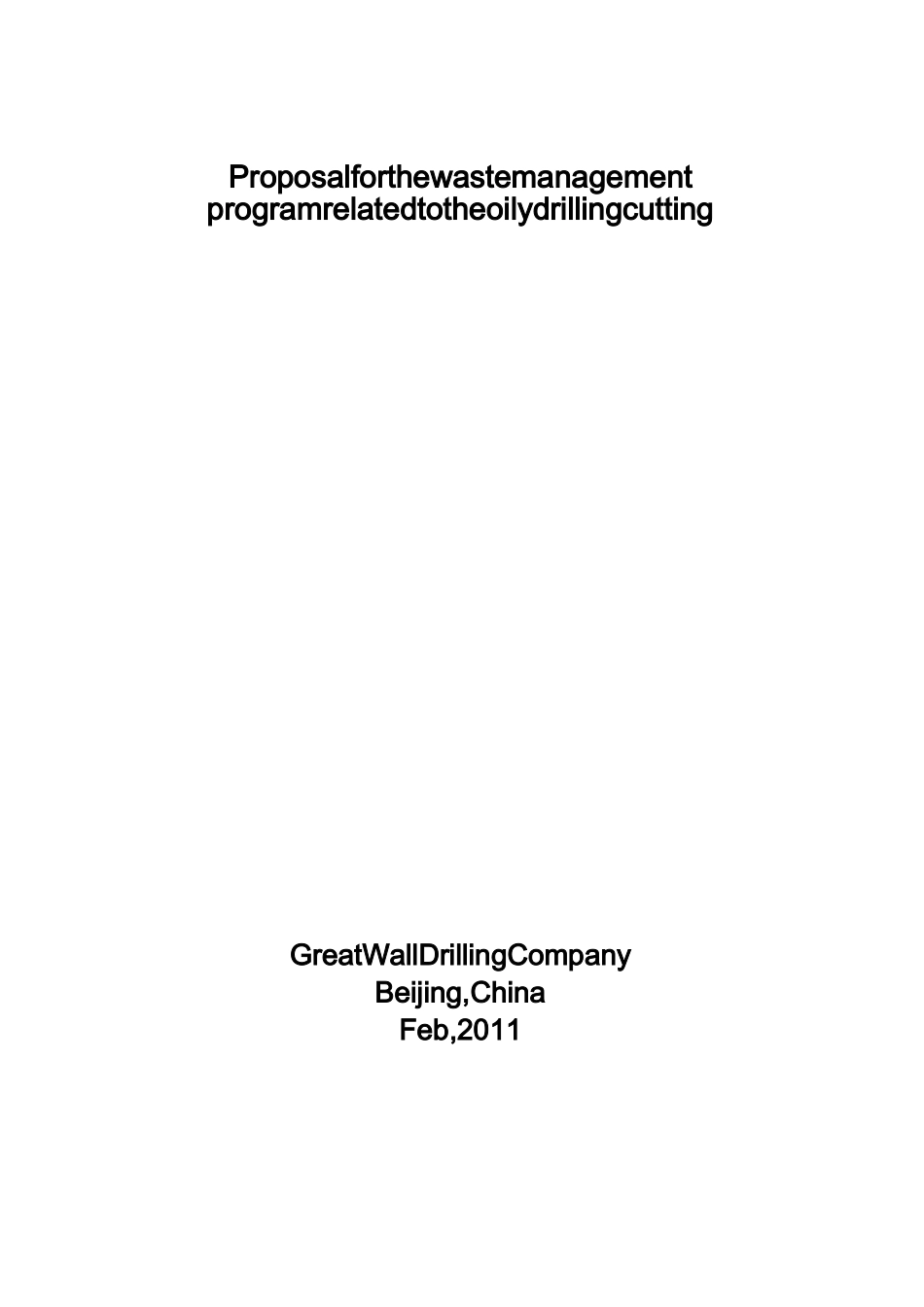

ProposalforthewastemanagementprogramrelatedtotheoilydrillingcuttingGreatWallDrillingCompanyBeijing,ChinaFeb,20111.IntroductionOilandgaswellscannotbedrilledwithoutcreatingwaste.However,withgoodwastemanagementpractices,theamountofwasteandthetoxicityofwastecanbereduced.Byfar,thegreatestvolumeofwastegeneratedinthedrillingprocessisdrilledcuttings.ThefirststepandperhapsthebestwastemanagementpracticeisgoodSolidscontrolequipment,includingshakers,mudconditioners,andcentrifuges.WithourlatesttechnologiesinDrillingWasteManagementServiceswestrivetoreducethewastegeneratedatsource,duringdrillingactivitiestoacceptableenvironmentallevels.OurwastemanagementservicesarebasedonourWasteManagementHierarchywhichgovernsthewaywedealwithSolidscontrolandwastedisposalinallourdrillingactivitiesworldwide.Alltheseserviceshavebeenstructuredanddesignedtomeettheincreasinglyhighenvironmentalstandardsrequiredbytheindustrywhenoperatinginevermoreremoteanddiverselocations.TheintegrationandmanagementofalltheseservicesbyGWDC'steamofspecialistsprovidestheClientwiththeconfidencethatanyprojectwillbecompletedinaccordancewiththehigheststandardspossible.2.ProposalforthewastemanagementprogramrelatedtotheoilydrillingcuttingTreatmentoftheNABMdrilledcuttingswillcomplywiththeWasteManagementProgramand/orCompany'sspecificationsandlocalrequirements.GWDCshallprovideVerticalCuttingsDryersequipmentpackageoffirststeptoreducetheOOC(OilonCuttings)to8-5%.Then,thesecondsteptousebioremediationtoreducetheOOC(OilonCuttings)tolessthan2%Step#1NABMSolidswastes-VerticalCuttingsDryersDisposalProcessDrillingwastefluid&wastecuttingsshallbetransferredfromshaleshakertodryeratwellsiteorintocollectingtankbyaugerconveyor;thewasteincollectingtankshouldbetransferredtomudplantordisposalsitetodryerforfurthertreatment.Processchart:TransfersystemCuttingsfromthefirstshaleshakershallbetransferredintocollectingtankforwastefluid&wastecuttings,therearestirringdeviceandpumpinthecollectingtank.Wastefluidfromdesander,desilterandcentrifugeshallbedischarge...