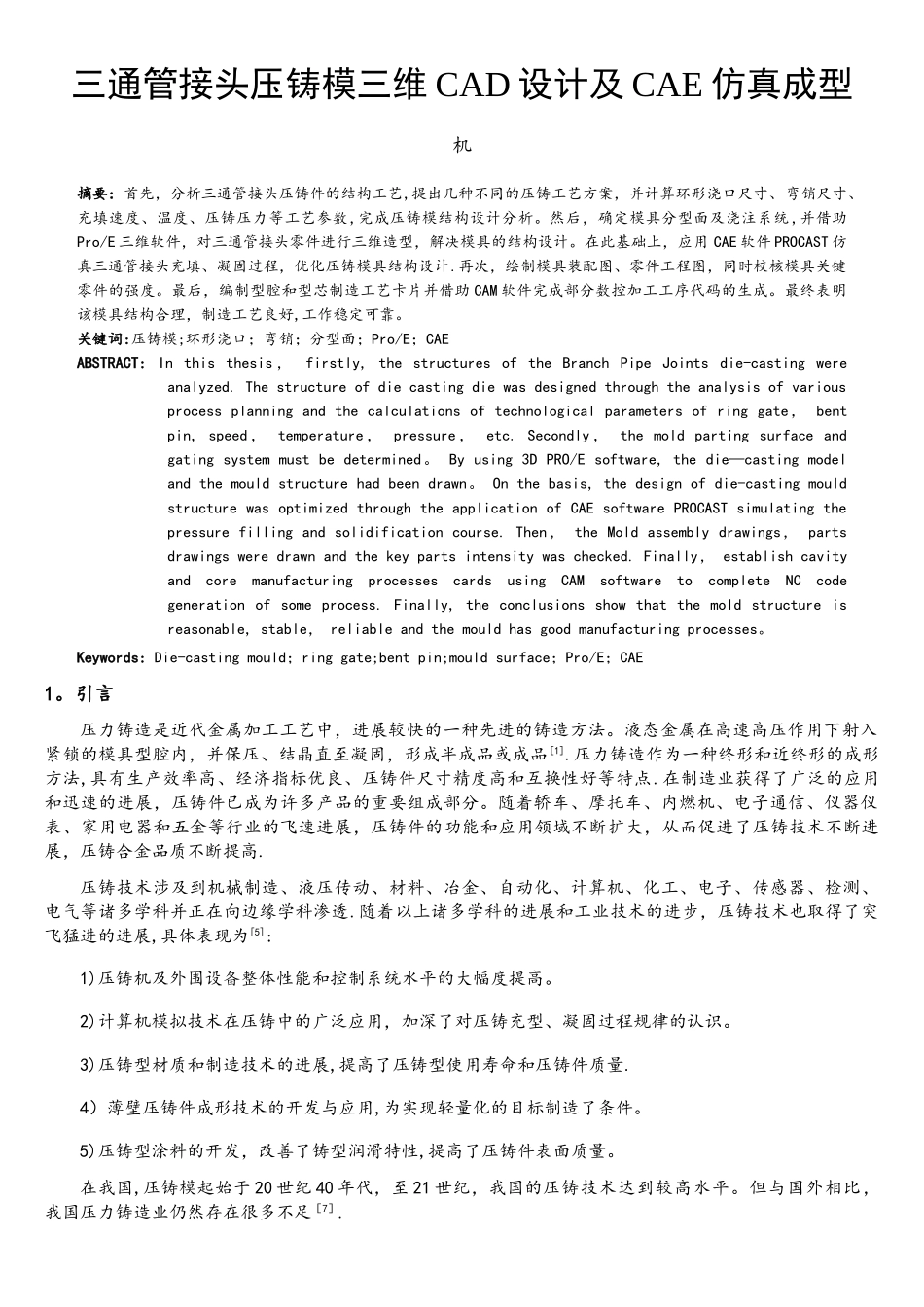

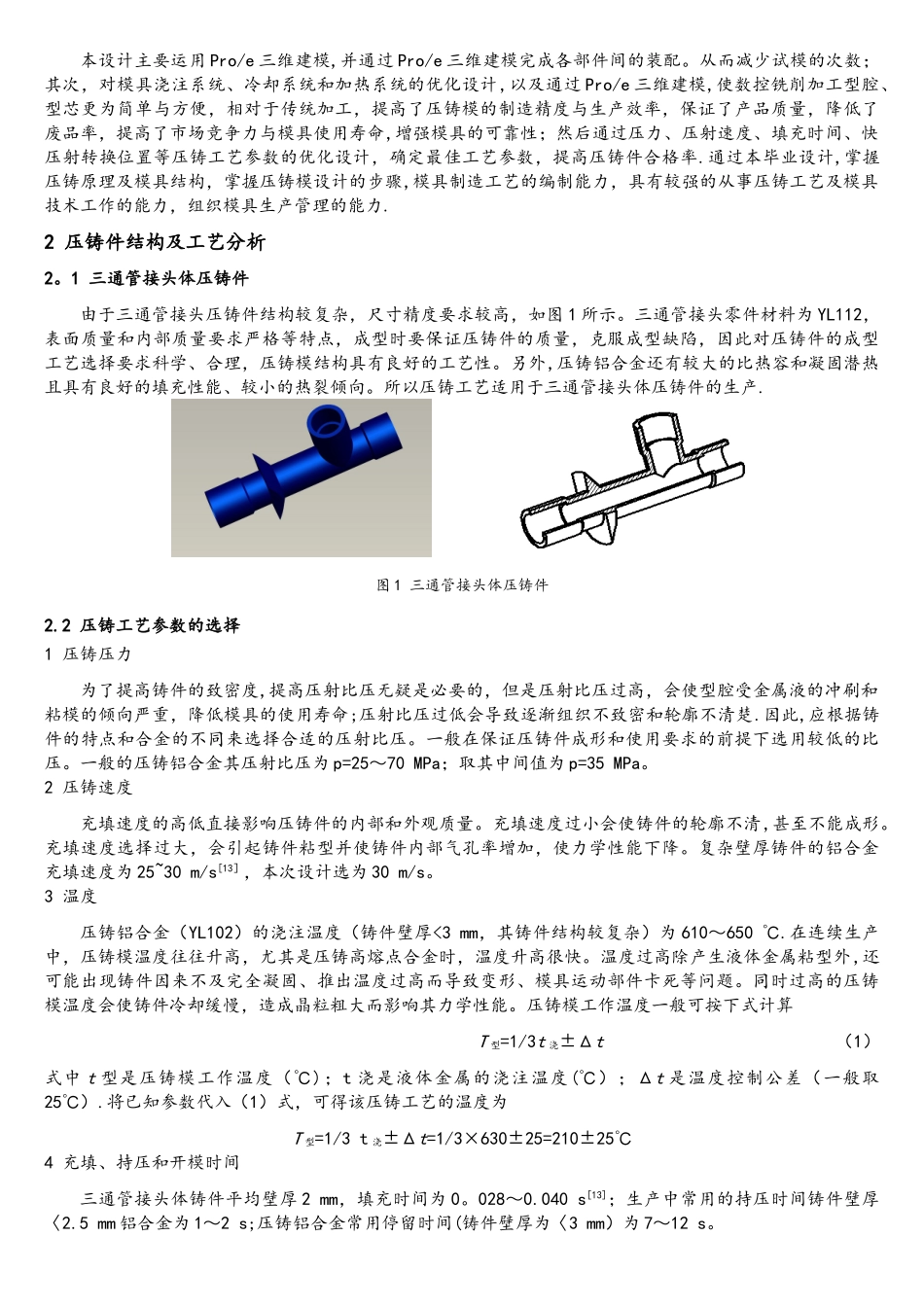

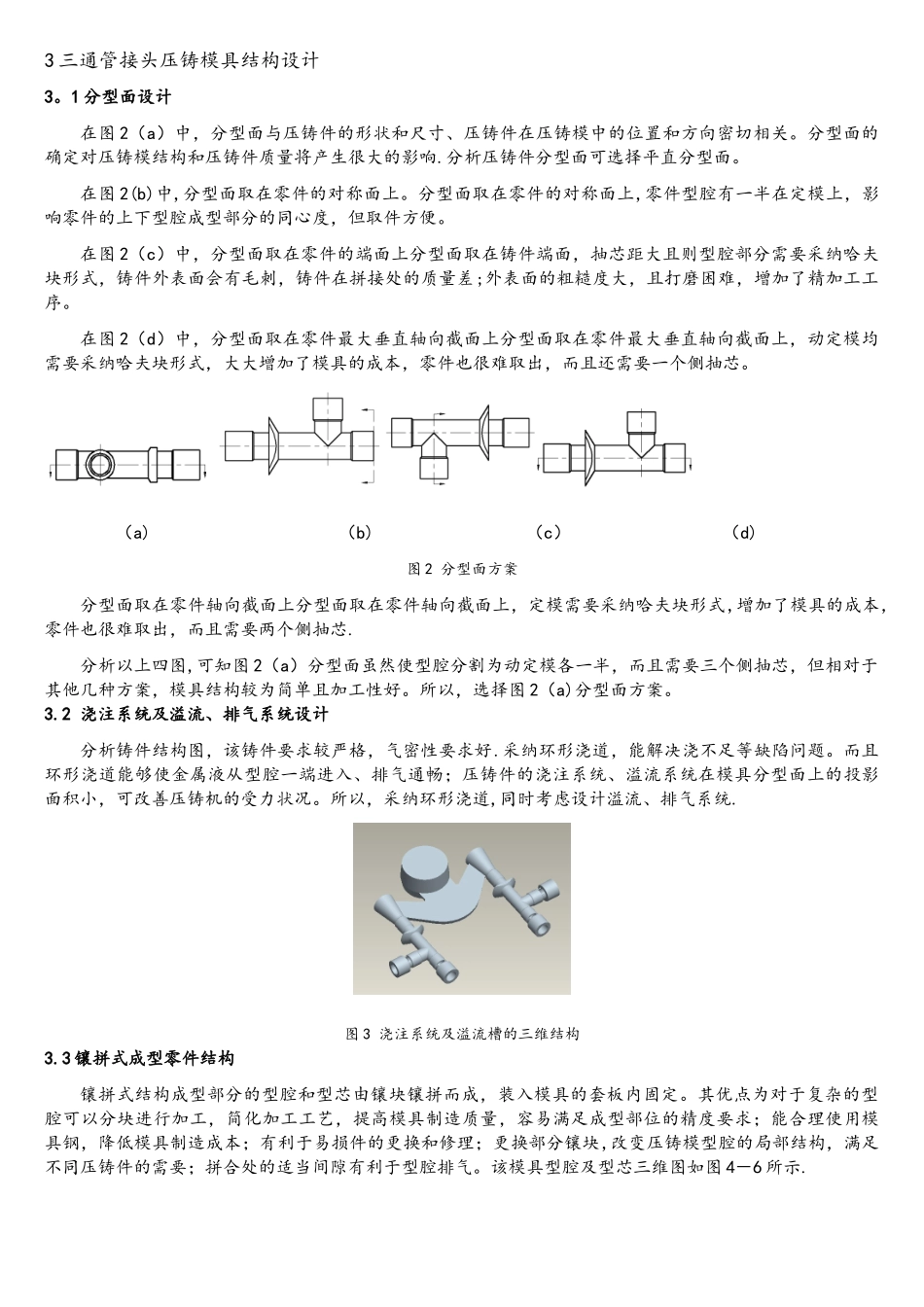

三通管接头压铸模三维 CAD 设计及 CAE 仿真成型机摘要:首先,分析三通管接头压铸件的结构工艺,提出几种不同的压铸工艺方案,并计算环形浇口尺寸、弯销尺寸、充填速度、温度、压铸压力等工艺参数,完成压铸模结构设计分析。然后,确定模具分型面及浇注系统 ,并借助Pro/E 三维软件,对三通管接头零件进行三维造型,解决模具的结构设计。在此基础上,应用 CAE 软件 PROCAST 仿真三通管接头充填、凝固过程,优化压铸模具结构设计.再次,绘制模具装配图、零件工程图,同时校核模具关键零件的强度。最后,编制型腔和型芯制造工艺卡片并借助 CAM 软件完成部分数控加工工序代码的生成。最终表明该模具结构合理,制造工艺良好,工作稳定可靠。关键词:压铸模;环形浇口;弯销;分型面;Pro/E;CAEABSTRACT: In this thesis , firstly, the structures of the Branch Pipe Joints die-casting were analyzed. The structure of die casting die was designed through the analysis of various process planning and the calculations of technological parameters of ring gate, bent pin, speed , temperature , pressure , etc. Secondly , the mold parting surface and gating system must be determined。 By using 3D PRO/E software, the die—casting model and the mould structure had been drawn。 On the basis, the design of die-casting mould structure was optimized through the application of CAE software PROCAST simulating the pressure filling and solidification course. Then, the Mold assembly drawings, parts drawings were drawn and the key parts intensity was checked. Finally, establish cavity and core manufacturing processes cards using CAM software to complete NC code generation of some process. Finally, the conclusions show that the mold structure is reasonable, stable, reliable and the mould has good manufacturing processes。Keywords: Die-casting mould;ring gate;bent pin;mould surface;Pro/E;CAE1。引言压力铸造是近代金属加工工艺中,进展较快的一种先进的铸造方法。液态金属在高速高压作...