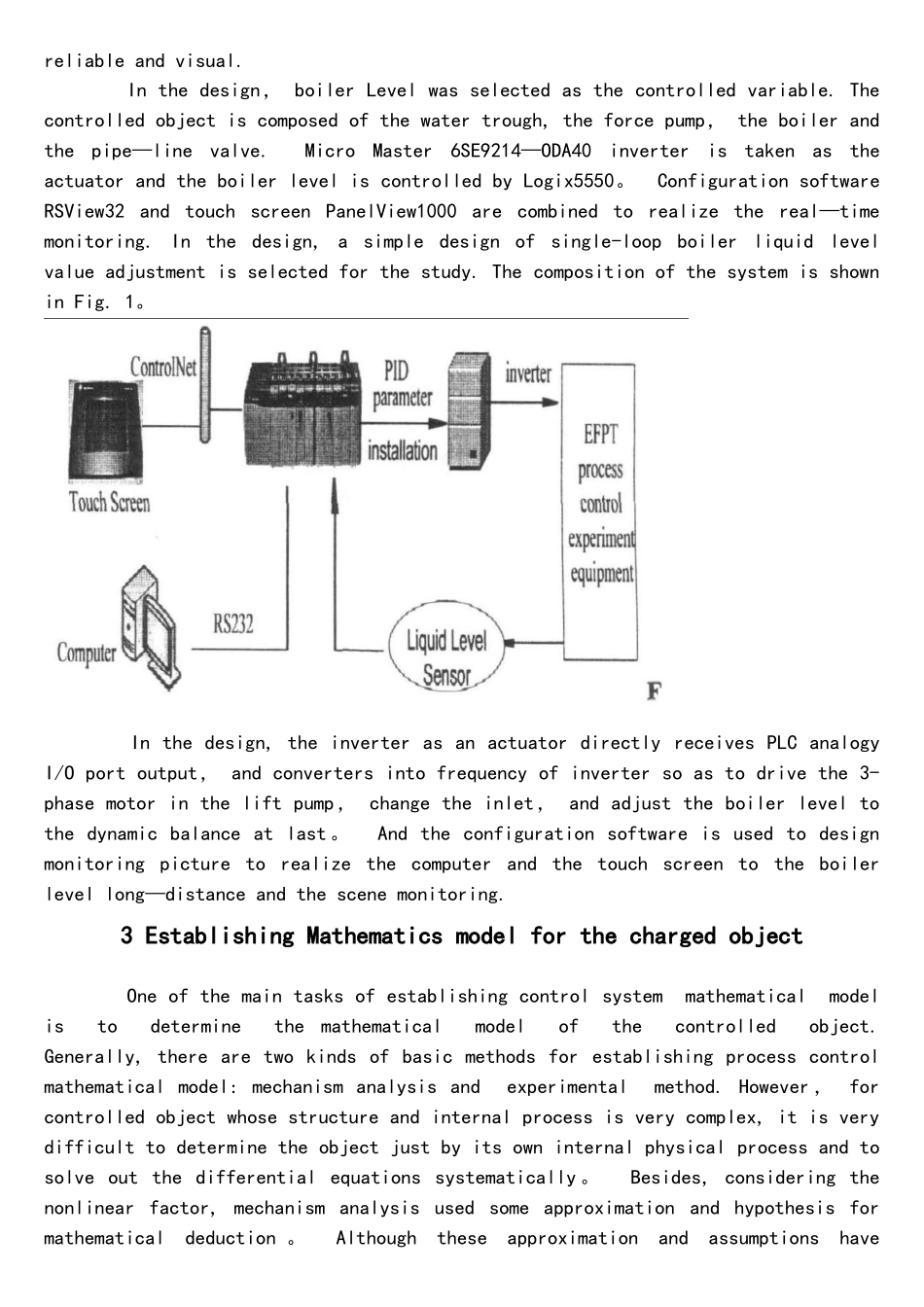

Boiler level control system based on ControlLogix5550 PLCAbstract-This paper is a research design based on EFPT process control device。 In the design, actual industry field has been simulated and corresponding modeling has been carried on for the boiler level system 。 Then the appropriate PID parameter has been sorted out and ControlLogia5550PLC has been used to control the entire boiler level system。At last, a corresponding control interface has been established and the boiler level has been under a safe and accurate controlKeywords:EFPT,PID,Modeling,Boiler level;1 IntroductionThe task of the industrial boiler level control is to maintain a dynamic balance by controlling the water flow and evaporation, so that the drum level can be maintained in the technological level, which is a necessity for ensuring safe operation and also one of the main indicators of the boiler’s normal operation. Water level which is too high will affect the effect of the steam-water separation, but too low it is will break ring cycle or even cause boiler explosion. To ensure a safe and efficient production, the boiler level must be strictly controlled in maintaining constant or changing only according to a certain rule。 Using Logix5550 PLC with analogy I/O modules , launched by Rockwell Automation Company as controllers, and EFPT process control experimental device as control object , this system have brought the boiler water level under an accurate control in a mini boiler system with sensors and actuators that used in industrial production.Fig。 1 Boiler level setting value adjustment system2 System Overview This system is composed of an EFPT process control device, an inverter, a Logix5550 PLC and a computer. EF...