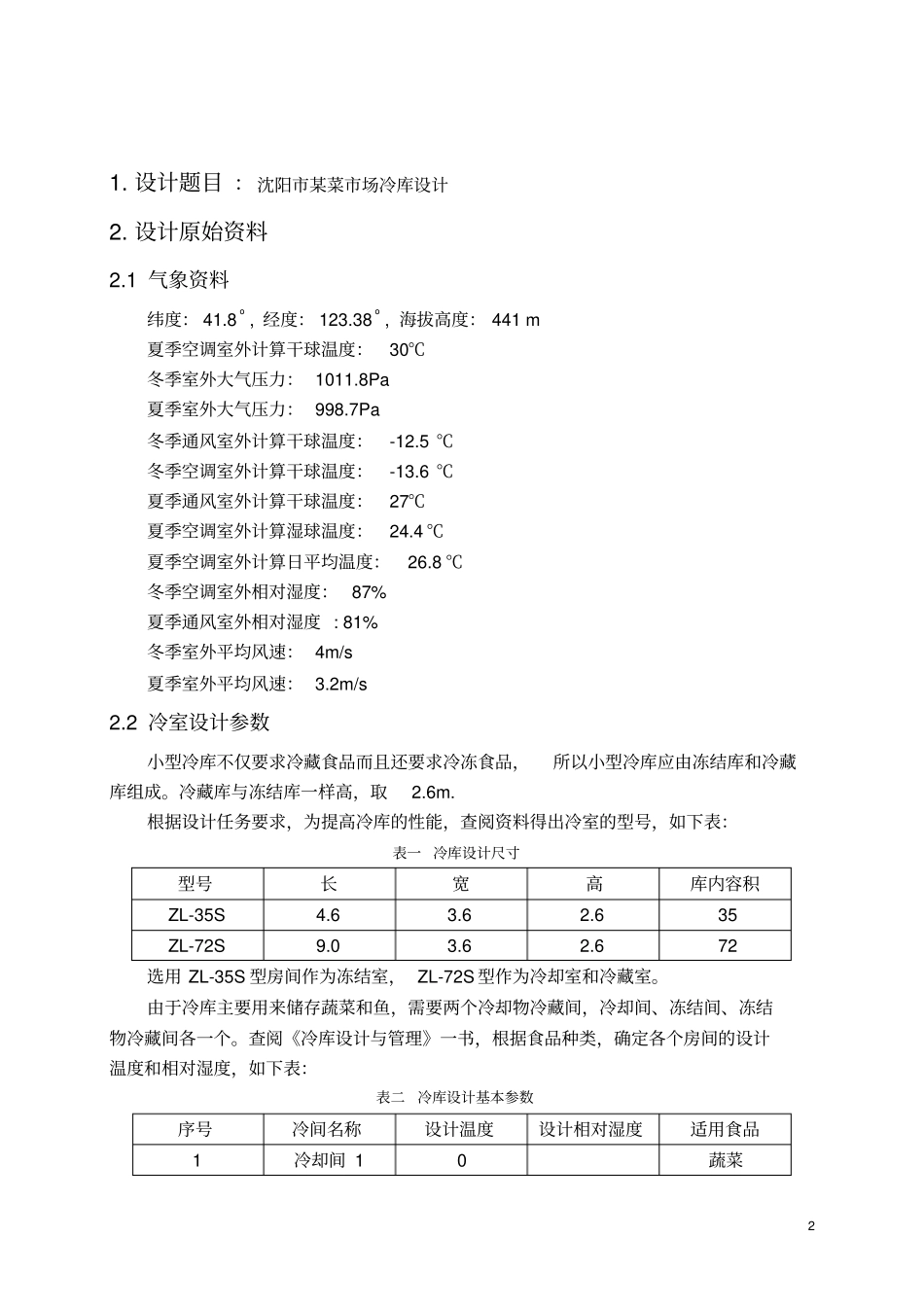

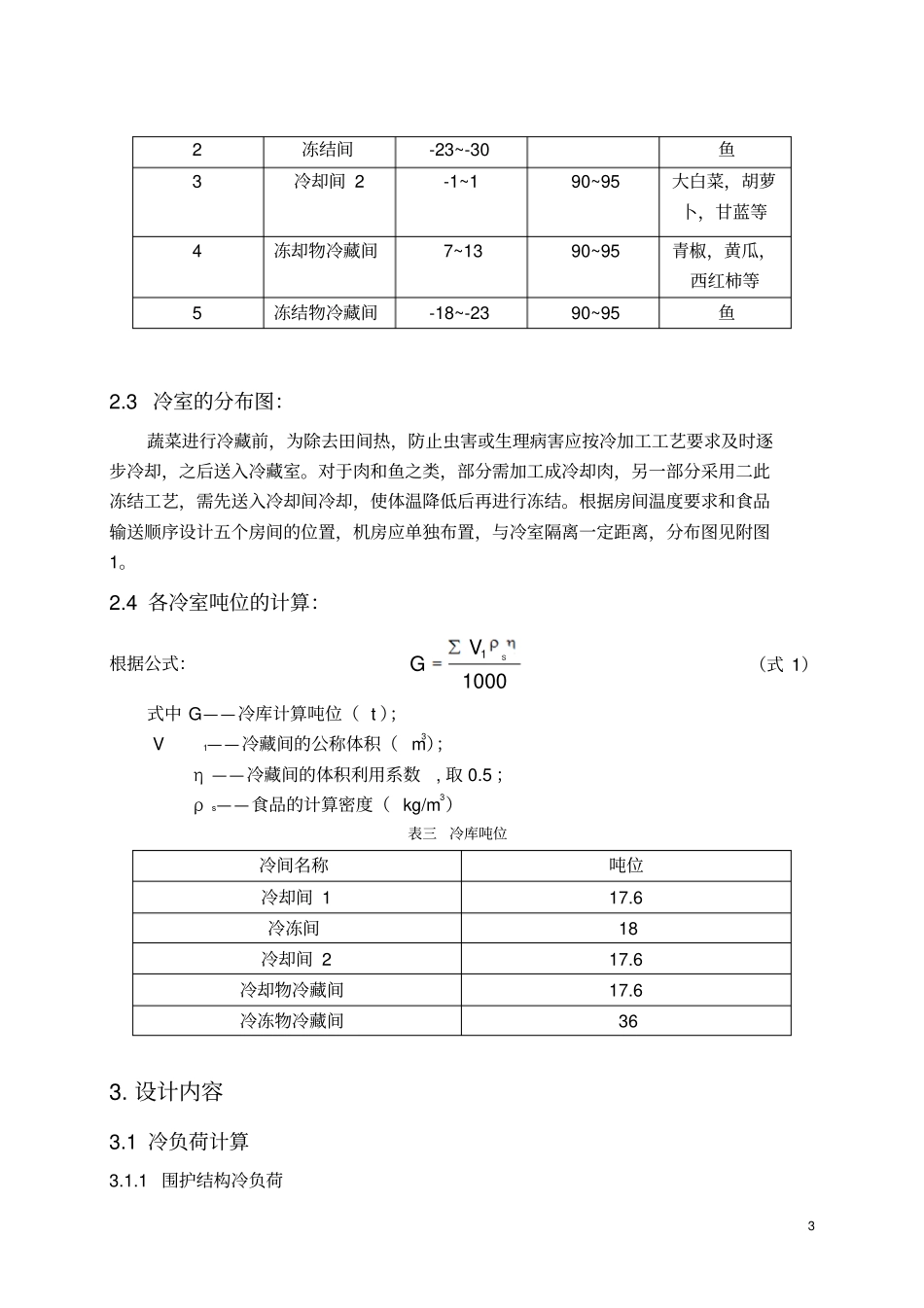

1目录1.设计题目······························································12.设计原始资料························································22.1室外气象参数···························································22.2冷室设计参数···························································22.3冷室分布图······························································32.4各个冷室吨位分配·····················································33.设计内容······························································33.1冷负荷的计算··················33.2制冷工况的确定·················73.3压缩机的选择计算················83.4冷凝器的选择计算················103.5蒸发器的选择计算················103.6膨胀阀的选择计算················123.7辅助设备的选择计算···············123.8供水方案的选择和管路计算⋯⋯⋯⋯⋯⋯⋯⋯⋯⋯⋯⋯⋯133.9制冷系统的流程图················14参考文献···········错误!未定义书签。521.设计题目:沈阳市某菜市场冷库设计2.设计原始资料2.1气象资料纬度:41.8o,经度:123.38o,海拔高度:441m夏季空调室外计算干球温度:30℃冬季室外大气压力:1011.8Pa夏季室外大气压力:998.7Pa冬季通风室外计算干球温度:-12.5℃冬季空调室外计算干球温度:-13.6℃夏季通风室外计算干球温度:27℃夏季空调室外计算湿球温度:24.4℃夏季空调室外计算日平均温度:26.8℃冬季空调室外相对湿度:87%夏季通风室外相对湿度:81%冬季室外平均风速:4m/s夏季室外平均风速:3.2m/s2.2冷室设计参数小型冷库不仅要求冷藏食品而且还要求冷冻食品,所以小型冷库应由冻结库和冷藏库组成。冷藏库与冻结库一样高,取2.6m.根据设计任务要求,为提高冷库的性能,查阅资料得出冷室的型号,如下表:表一冷库设计尺寸型号长宽高库内容积ZL-35S4.63.62.635ZL-72S9.03.62.672选用ZL-35S型房间作为冻结室,ZL-72S型作为冷却室和冷藏室。由于冷库主要用来储存蔬菜和鱼,需要两个冷却物冷藏间,冷却间、冻结间、冻结物冷藏间各一个。查阅《冷库设计与管理》一书,根据食品种类,确定各个房间的设计温度和相对湿度,如下表:表二冷库设计基本参数序号冷间名称设计温度设计相对湿度适用食品1冷却间10蔬菜32冻结间-23~-30鱼3冷却间2-1~190~95大白菜,胡萝卜,甘蓝等4冻却物冷藏间7~1390~95青椒,黄瓜,西红柿等5冻结物冷藏间-18~-2390~95鱼2.3冷室的分布图:蔬菜进行冷藏前,为除去田间热,防止虫害或生理病害应按冷加工工艺要求及时逐步冷却,之后送入冷藏室。对于肉和鱼之类,部分需加工成冷却肉,另一部分采用二此冻结工艺,需先送入冷却间冷却,使体温降低后再进行冻结。根据房间温度要求和食品输送顺序设计五个房间的位置,机房应单独布置,与冷室隔离一定距离,分布图见附图1。2.4各冷室吨位的计算:根据公式:10001SVG(式1)式中G——冷库计算吨位(t);V1——冷藏间的公称体积(m3);η——冷藏间的体积利用系数,取0.5;ρs——食品的计算密度(kg/m3)表三冷库吨位冷间名称吨位冷却间117.6冷冻间18冷却间217.6冷却物冷藏间17.6冷冻物冷藏间363.设计内容3.1冷负荷计算3.1.1围护结构冷负荷4(1)隔热材料。材料导热系数的大小是材料隔热性能的决定因素,导热系数越小,保温隔热性能就越好。硬质聚氨酯泡沫塑料具有非常优越的绝热性...