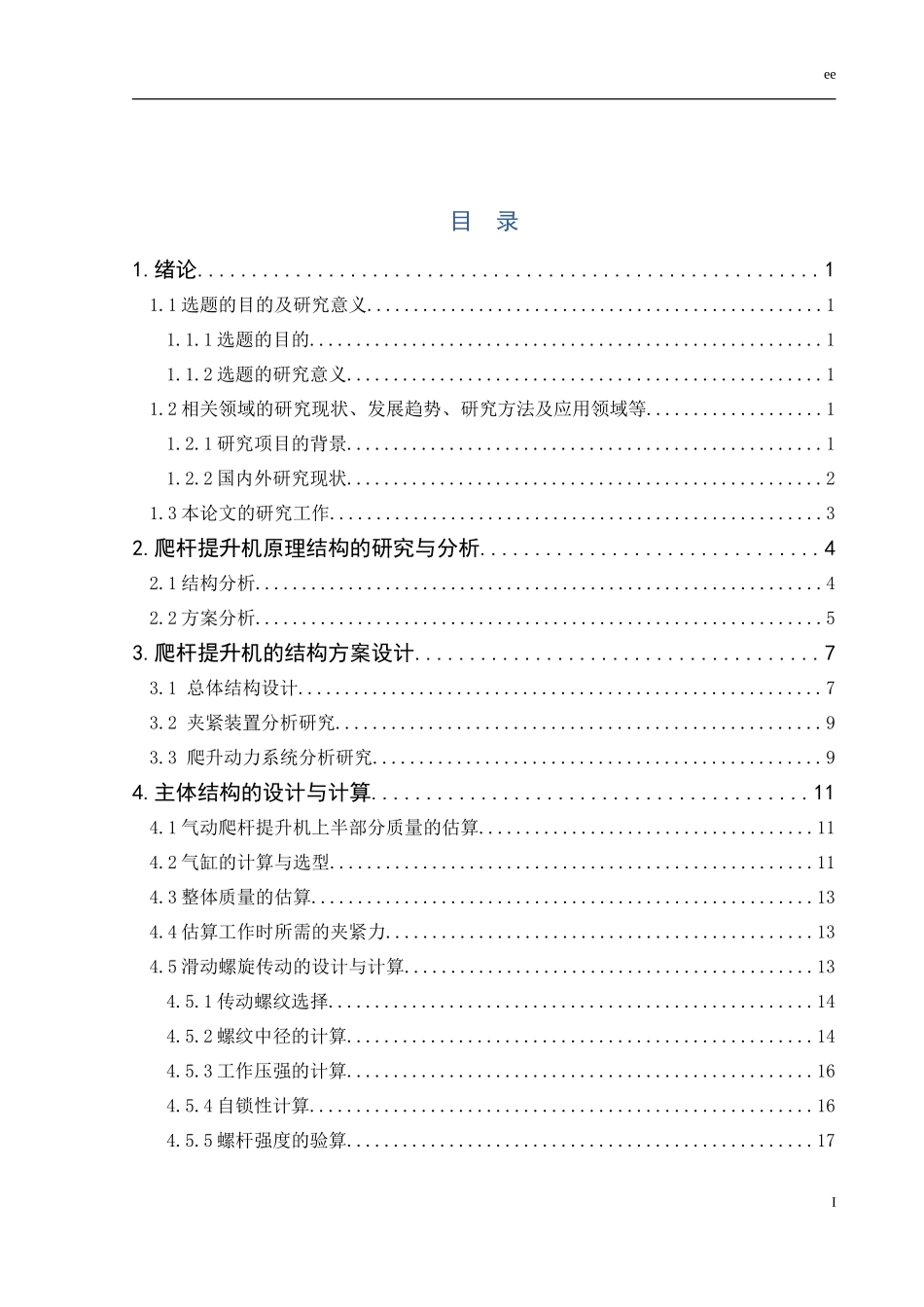

ee气动式爬杆提升机设计e(e)指导教师:e【摘要】首先查找资料文献,研究分析各种攀爬机构,比较各类爬行机构的优劣,找出它们的优缺点。然后提出爬杆提升机的设计方案,确定本体的大致结构。在此基础上详细阐述了爬杆提升机模块化设计的理念。根据垂直电杆、管道的尺寸数据,分为模块进行设计计算,然后经过合理的组合装配,完成气动爬杆提升机的设计。【关键词】提升机;爬杆;攀爬eeDesignofpneumaticpole-climbinghoiste(e)Tutor:eAbstract:Firstfindthedataandliterature,researchandanalysisofvariousclimbingorganizations,comparetheprosandconsofallkindsofcrawlingbodies,identifyingtheirstrengthsandweaknesses.Andthenmakepole-climbinghoistdesign,determiningthegeneralstructureoftheontology.Thisclimbingelevatoriselaboratedonthebasisofmodulardesignconcept.Accordingtotheverticalpoles,pipesofdimensiondata,calculationisdividedintomodules,andthenafterareasonablecombinationofAssembly,completedesignofpneumaticpole-climbinghoist.Keywords:hoist;pole-climbing;speelee目录1.绪论.........................................................11.1选题的目的及研究意义.................................................11.1.1选题的目的.......................................................11.1.2选题的研究意义...................................................11.2相关领域的研究现状、发展趋势、研究方法及应用领域等...................11.2.1研究项目的背景...................................................11.2.2国内外研究现状...................................................21.3本论文的研究工作.....................................................32.爬杆提升机原理结构的研究与分析...............................42.1结构分析.............................................................42.2方案分析.............................................................53.爬杆提升机的结构方案设计.....................................73.1总体结构设计........................................................73.2夹紧装置分析研究....................................................93.3爬升动力系统分析研究................................................94.主体结构的设计与计算........................................114.1气动爬杆提升机上半部分质量的估算....................................114.2气缸的计算与选型....................................................114.3整体质量的估算......................................................134.4估算工作时所需的夹紧力..............................................134.5滑动螺旋传动的设计与计算............................................134.5.1传动螺纹选择....................................................144.5.2螺纹中径的计算..................................................144.5.3工作压强的计算..................................................164.5.4自锁性计算......................................................164.5.5螺杆强度的验算..................................................17Iee4.5.6螺母螺纹强度验算................................................174.5.7螺杆的稳定性验算................................................194.5.8螺杆横向振动的验算..............................................204.6气动马达的设计计算与选型............................................214.6.1气动马达的选择缘由..............................................214.6.2气动马达的设计计算..............................................224.6.3气动马达的选型..................................................244.7齿轮传动部分的设计与计算.......................