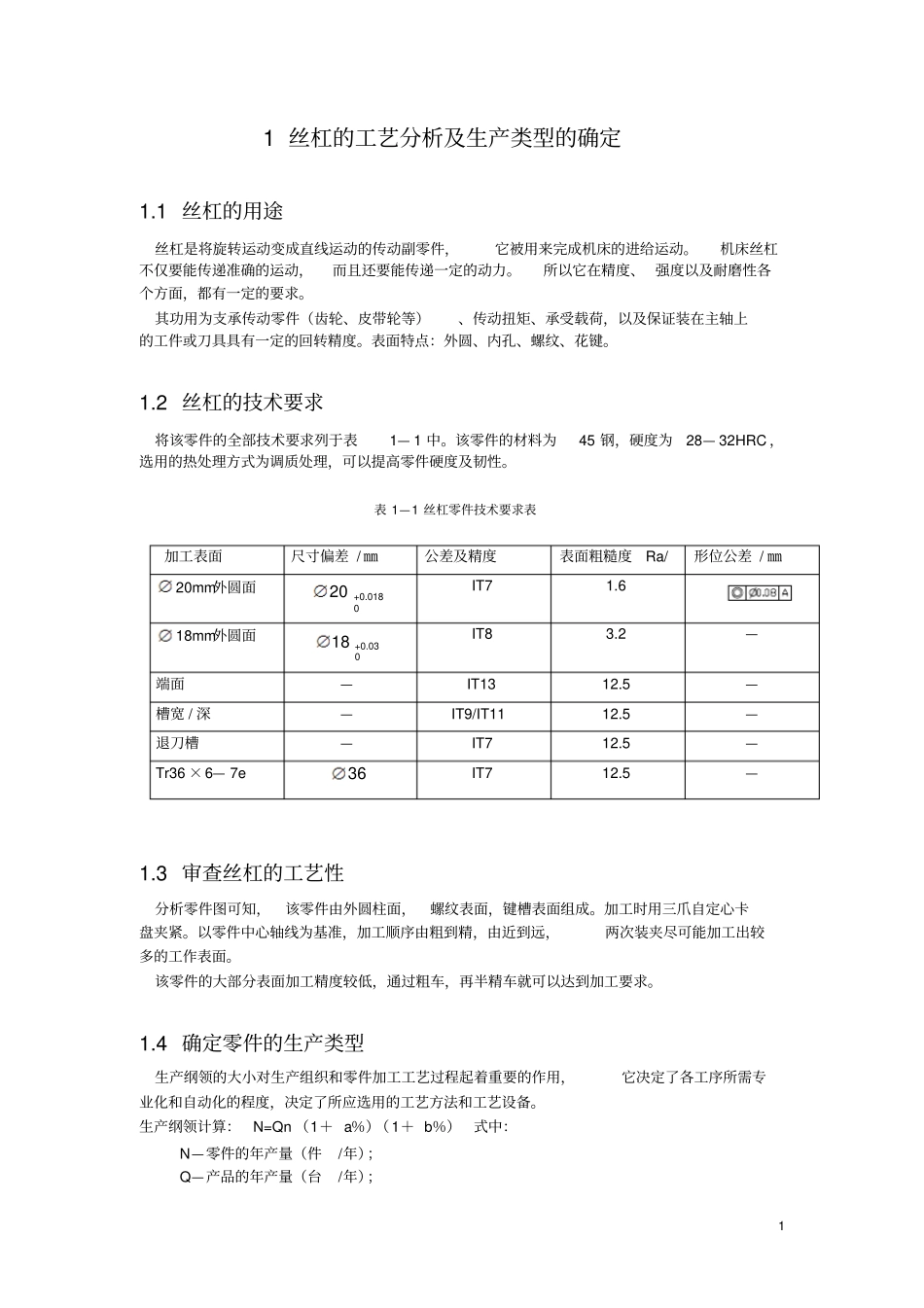

目录1丝杠的工艺分析及生产类型的确定..............................................11.1丝杠的用途..............................................................11.2丝杠的技术要求..........................................................11.3审核丝杠的工艺性........................................................11.4确定丝杠的生产类型......................................................12确定毛坯、绘制毛坯简图......................................................22.1选择毛坯................................................................22.2确定毛坯的尺寸公差和机械加工余量........................................22.3、绘制毛坯简图...........................................................23拟定丝杠工艺路线............................................................23.1定位基准的选择..........................................................23.1.1粗基准的选择........................................................33.1.2精基准的选择........................................................33.2各表面加工方案的确定....................................................33.3加工阶段的划分..........................................................33.4工序的集中与分散........................................................33.5工序顺序的安排..........................................................43.5.1机械加工工序........................................................43.5.2热处理工序..........................................................43.5.3辅助工序............................................................43.6机床设备及工艺设备的选用................................................43.6.1机床设备的选用......................................................43.6.2工艺装备的选用......................................................43.7确定工艺路线............................................................44确定加工余量和工序尺寸......................................................54.1工序-粗车外圆端面及台阶.................................................54.2工序—车梯形螺纹........................................................54.2.1工序加工过程........................................................54.2.2确定工序尺寸........................................................54.3工序—粗铣..............................................................64.4工序—半精车精车外圆....................................................74.4.1工序精车外圆........................................................74.4.2工序半精加工外圆....................................................75确定切削用量及时间定额......................................................75.1工序-粗车外圆端面及台阶................................................75.1.1确定切削用量........................................................75.1.2时间定额的计算......................................................75.2工序—车梯形螺纹........................................................85.2.1确定切削用量........................................................85.2.2时间定额的计算......................................................95.3工序—铣削.............................................................105.4工序—半精车精车外圆...................................................115.4.1确定切削用量.......................................................115.4.2时间定额的计算.....................................................126总结....