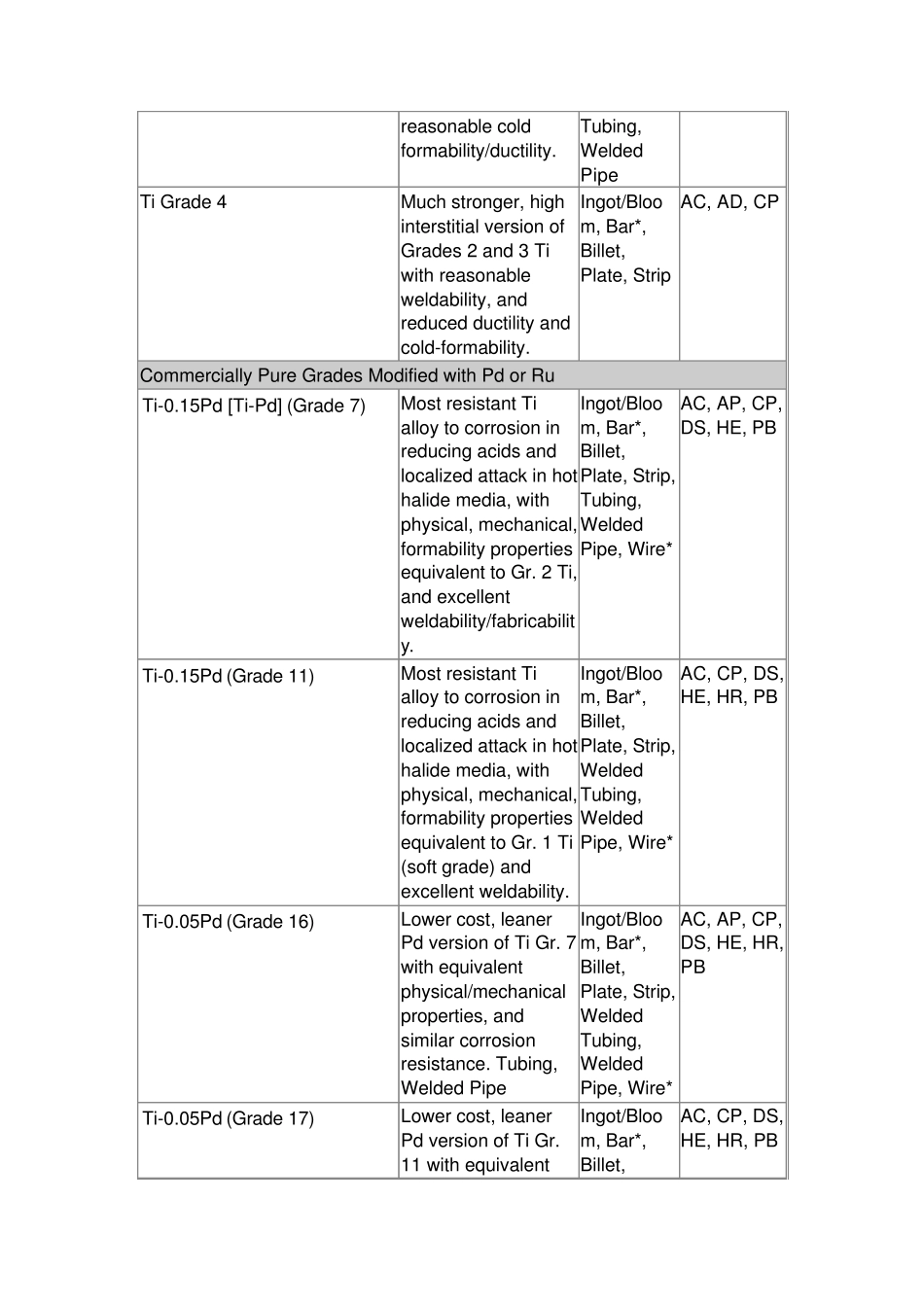

Alloy Guide A Guide to Commercial Titanium Alloys Alloy Composition (ASTM Grade) [Common Name] Alloy Description Available Product Forms Typical Applications Commercially Pure (Unalloyed) Ti Grades Ti Grade 1 Lower strength, softest, unalloyed Ti grade with highest ductility, cold formability, and impact toughness, with excellent resistance to mildly reducing to highly oxidizing media with or without chlorides and high weldability. Ingot/Bloom, Bar*, Billet, Plate, Strip, Welded Tubing, Welded Pipe, Wire* AC, CG, CP, DS, HE, HR, FP, MI, PB, NS Ti Grade 2 Moderate strength unalloyed Ti with excellent weldability, cold formability, and fabricability; "workhorse" and "garden variety" Ti grade for industrial service with excellent resistance to mildly reducing to highly oxidizing media with or without chlorides. Approved for sour service use under the NACE MR-01-75 Standard. Ingot/Bloom, Bar*, Billet, Plate, Strip, Welded Tubing, Welded Pipe, Seamless Tubing*, Wire*, Foil* AC, AD, AP, AR, CG, CP, DS, FP, HE HR, MI, NS, PB, PP, OP, SR Ti Grade 3 Slightly stronger version of Gr. 2 Ti with similar corrosion resistance with good weldability and Ingot/Bloom, Bar*, Billet, Plate, Strip, Welded CP, NS, PP reasonable cold formability/ductility. Tubing, Welded Pipe Ti Grade 4 Much stronger, high interstitial version of Grades 2 and 3 Ti with reasonable weldability, and reduced ductility and cold-formability. Ingot/Bloom, Bar*, Billet, Plate, Strip AC, AD, CP Commercially Pure Grades Modified with Pd or Ru Ti-0.15Pd [Ti-Pd] (Grade 7) Most resistant Ti alloy to corrosion in reducing acids and localized attack in hot halide media, with physical, mechanical, formability properties equivalent to Gr. 2 Ti, and excellent weldabi...