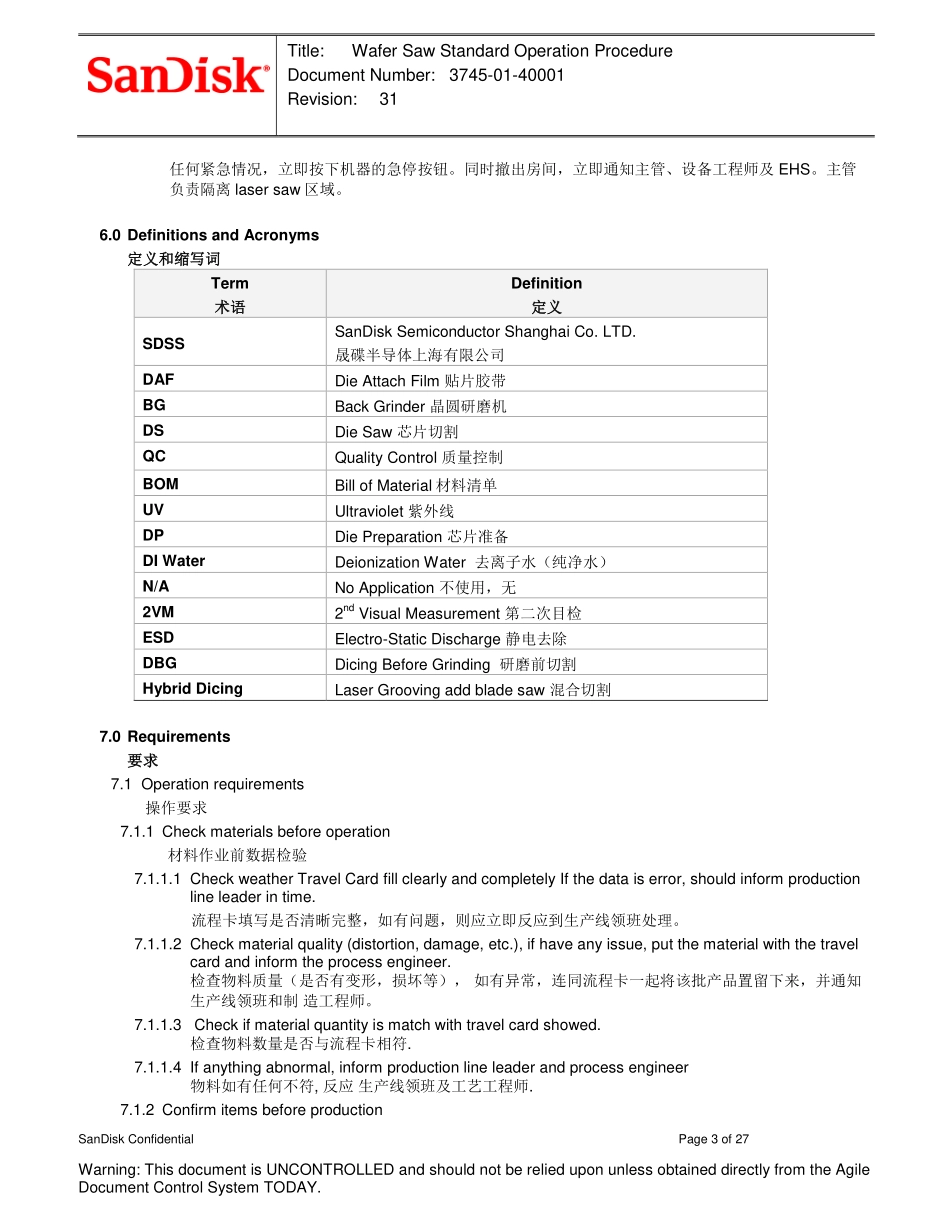

Title:WaferSawStandardOperationProcedureDocumentNumber:3745-01-40001Revision:31SanDiskConfidentialPage1of27Warning:ThisdocumentisUNCONTROLLEDandshouldnotberelieduponunlessobtaineddirectlyfromtheAgileDocumentControlSystemTODAY.1.0Purpose目的ThepurposeofthisprocedureistoestablishwafersawstandardoperationforSDSSproducts.本规范的目的是建立SDSS晶圆切割工序程序书。2.0Scope范围ThisprocedureisappliedforSDSSproducts.本规范仅适用于所有SDSS的产品。3.0RolesandResponsibilities角色和职责3.1Primaryownerdepartment:ProcessEngineering拟定部门:工艺工程部3.2Review,approvalandimplementationdepartment(s):Q&RDepartment,ProcessEngineering,ProductionDepartment,EquipmentMaintenanceDepartment.评审,批准和执行部门:质量部,工艺工程部,生产部,设备维护部4.0ReferenceDocuments参考文件No..编号Source来源Title/Description标题/描述1111-02-20001AgileProcessControlPlan3712-02-00017AgileInternalVisualInspectionCriteria3715-01-00003AgileESDControlProcedure2041-02-00017AgileIndirectmaterialspec0000-02-00002AgileProcessFMEA-DiePreparation3743-02-00006AgileDirectmaterial&keysupplycontrolworkinstruction3712-01-00006AgileQDNProcedure3745-02-40005AgileOCAPofwafersawprocess5.0Materials,Equipment,ToolsandSafety材料、设备、工具和安全5.1Equipmentandmaterial设备、材料和工具WaferDicer晶圆切割机DAFLasergrooving激光切割机DAFexpanding晶圆分离机CO2BUBBLER二氧化碳发生器SawBlade划片刀LowPowerMicroscope低倍显微镜HighPowerMicroscope低倍显微镜Measurementscope500X500倍测量显微镜Frame铁圈FrameCassette提篮FingerCoats指套Title:WaferSawStandardOperationProcedureDocumentNumber:3745-01-40001Revision:31SanDiskConfidentialPage2of27Warning:ThisdocumentisUNCONTROLLEDandshouldnotberelieduponunlessobtaineddirectlyfromtheAgileDocumentControlSystemTODAY.ConductiveShoes导电鞋GroundedWorkTable接地工作台MarkPen记号笔Maskliquid保护液LasergroovingforLow-kwafer激光切割机5.2Safety安全5.2.1Alwayskeepalltables,shelvesandmachinecoverclean.所有工作台,架子和机台外壳,必须保持清洁.5.2.2Alloperatorsshouldwearconductiveshoesandfingercotsonallfingers,maskwhilehandlingproducts.所有操作工在加工产品时必须穿戴导电鞋和指套(所有的手指都戴上)以及口罩.5.2.3Therevolutionofdicerspindleisquitehigh,becarefulnoanyoperationwithmachinecoveropensallowed切割机主轴高速旋转,不允许在机器盖板打开的状况下进行任何操作5.2.4Emergencycase紧急情况5.2.4.1Incaseofemergencypowerfail,turnoffalltheswitch,takeoutmaterial,thencontactwithfacilitytoconfirmthepowerandairpressure.Aftergettingfacility’sconfirm,poweronthemachineagain.如遇紧急停电,首先应将机台的开关全部关闭,将物料清点,各自放到相应的位置,来电后直至厂务确定没有问题.电压,气压都稳定后方可重新开机生产5.2.4.2Incaseoffire,turnoffmachine,gotosafetyplace(followedtheescapeway)asquicklyaspossible.Afterthefirealarm,returntoonsite,andcheckthemachineandmaterial如遇火警,把机台的电源关闭,随同所有人员迅速离开,到安全地点集合,火警解除后进入厂内检查机台的情况及物料的情况5.2.4.3Anyabnormalcase,tostopmachine.任何异常情况请首先停机,等待技术员和工程师做确认。5.2.5Shouldbecarefultopreventmachineelectrical&mechanicalinjurywhenusemachine.Innormalproduction,don’topenthemachinecover.使用机器时请注意防止电气和机械伤害。正常生产时,请不要打开机器的盖子5.2.5.1Shouldturnedoff,whenmakemaintenance当需要做设备维护时须关闭电源5.2.5.2Shouldmaketheinterlockopenedwhenmakemaintenance,ifshouldkeeppoweron在必需开机状态下做维护时,须确保互锁装置工作5.2.5.3Makesuretheelect...