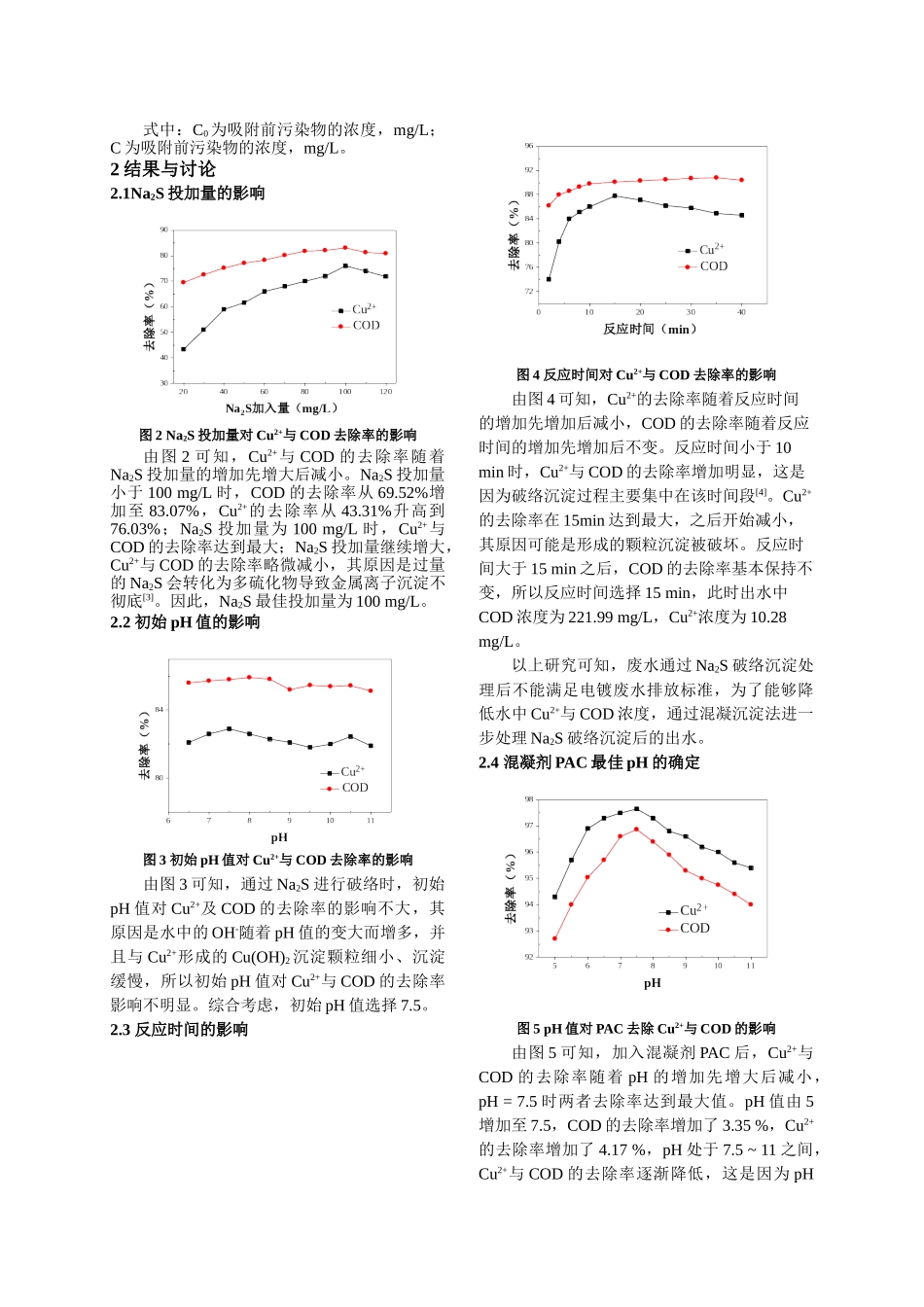

Na2S 破络与混凝沉淀组合处理电镀废水的研究摘要:电镀废水不仅能够污染环境,并且对人体造成伤害。本文通过 Na2S 破络与混凝沉淀组合处理电镀废水中 Cu2+与 COD,分析了 Na2S 投加量、初始 pH 值与反应时间等因素对电镀废水处理效果的影响。结果表明,最佳处理条件为:Na2S 投加量 100 mg/L,初始 pH 值 7.5,反应时间选择 15 min,PAC 混凝 pH 为 7.5,PAC 投加量为 8.0 mg/L,混凝时间为 6 min,PAM 投加量为 8.0 mg/L,沉降时间为 50 min,出水中 Cu2+浓度为 0.43 mg/L,COD 浓度为 41.26 mg/L,能够达到电镀废水排放标准。关键字:Na2S;电镀废水;Cu2+;COD;混凝沉淀Study on the Treatment of Electroplating Wastewater by the Combination of Na2S Network and Coagulation SedimentationAbstract: Electroplating waste water can not only pollute the environment, but also cause harm to the human body. In this paper, Cu2+ and COD in electroplating wastewater were treated by combination of Na2S network and coagulation and sedimentation. The effects of dosage of sodium sulfide, initial pH value and reaction time on electroplating wastewater treatment were analyzed. The results showed that the optimal treatment conditions were Na2S dosage 100 mg/L, initial pH 7.5, reaction time 15 min, PAC coagulation pH 7.5, PAC dosage 8.0 mg/L, coagulation time The dosage of PAM was 8.0 mg/L, the settling time was 50 min, the concentration of Cu2+ in the effluent was 0.46 mg/L and the COD concentration was 60.96 mg/L at 6 min, which could meet the electroplating wastewater discharge standards.Key words: Na2S; electroplating wastewater; Cu2+; COD; coagulation and sedimentation;0 引言电镀废水作为工业最难处理 的废水之一[1],其主要成分包括重金属废水与有机废水,重金属废水大部分为金属络合形态,水质复杂难以处理。化学沉淀法是一种比较成熟的废水处理方法,利用 Na2S 处理废水不仅能够破坏重金属的络合形态,而且可以形成硫化物沉淀,达到去除废水中污染物的目的...